Theme

Digital Transformation

Green Transformation

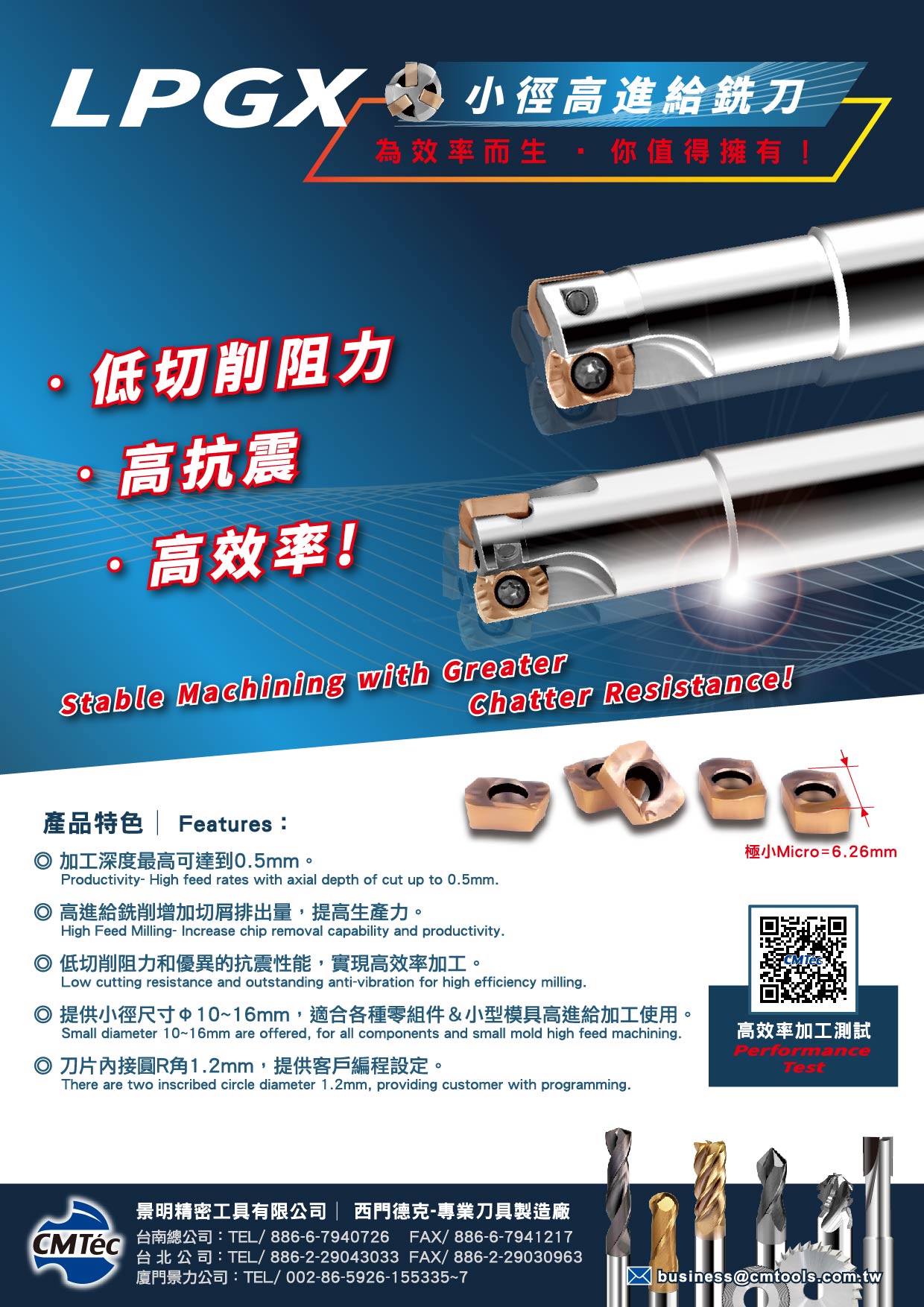

CHIN MING PRECISION TOOLS CO., LTD.

Product Description :

★ Productivity- High feed rates with axial depth of cut up to 0.5mm.

★ High Feed Milling- Increase chip removal capability and productivity.

★ Low cutting resistance and outstanding anti-vibration for high efficiency milling.

★ diameter 10~16mm are offered, for all components and small mold high feed machining.

★ There are two inscribed circle diameter 1.2mm, providing customer with programming.

TAIWAN 3AXLE TECHNOLOGY CO., LTD

Product Description :

Colour Marking Fiber Laser

Marking Machine

Good for metal materials, All polycarbonate material, plastic Stainless steel and other metal materials surface marking.

Laser safty goggles, Simple Fixture, External red light, Foot Switch.

Taiwan laser marking software

Availavle in 9 languages, English, Traditional/Simplified Chinese, German, Japanese, Polish, Portuguese, Turkish, Vietnamese, Portuguese, Turkish, Vietnamese.

Deep engraving, Metal marking, Serial number, QR code, Data matrix all in one machine.

Auto focus up to 4cm.

3D Rotary up 120º degree.

GREEN ECO PRO CO. LTD.

Product Description :

Chip Vacuum Removal System

FC Series

Used by Negative vacuum principle, and increase high absorption of air to get filter cycle. Intercept particulate matter and impurity.

Processing cycle

Zero Power consumption

CNC Machine No Stop

Waste material a few water

No Consumable

Reduce wastage of coolant

Promote Volume of Water Tank

Promote productivity

LEADWELL CNC MACHINES MFG., CORP.

Product Description :

Twin spindle & twin turret design, it can turn the different parts on the spindle and identical parts on both spindles at the same time. Integrated with 3-axis robot arms, to reach different OP and automation requested. Considering the turning efficiency, with automation high-speed robot reduces the loading/unloading time, with a high rigidity stricture design to increase the stability. On the other hand, the multiple types of robot arms will be able to satisfy the different demands of the client.

Max. swing: 290mm

Max. turning diameter: 290mm

Max. turning length: 220mm

X-axis travel: 195+5mm

Z-axis travel: 300mm

Spindle speed: 3500rpm

Spindle nose: A2-6

Chuck size: 10"

Spindle motor power: 11/15kw

Number of tool stations: 12T

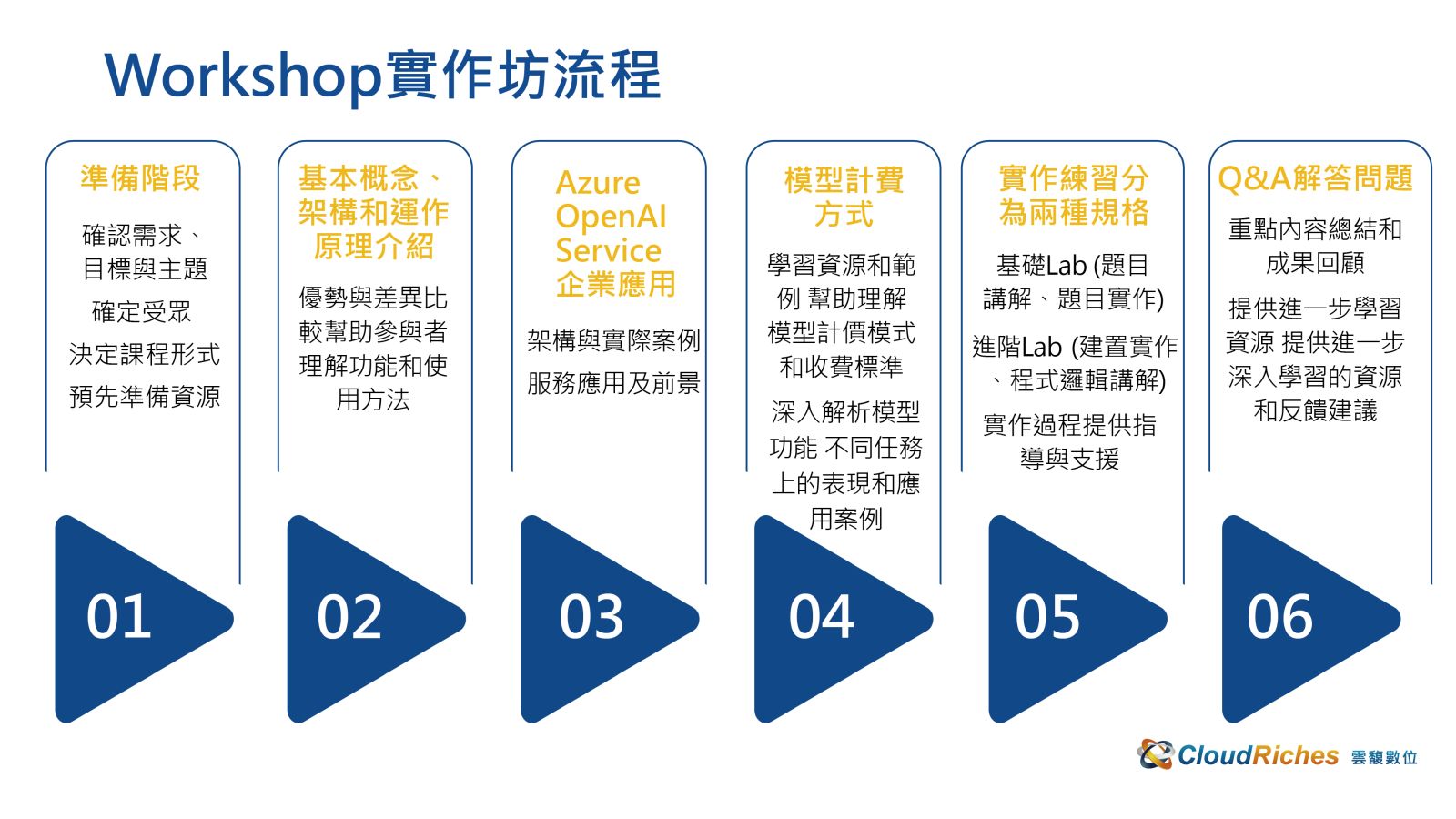

CloudRiches Digital Technology Co., Ltd

Product Description :

雲馥數位 開設企業級別的 Azure OpenAI Service 技術工作坊,提供更符合企業需求的Azure OpenAI 服務,並由解決方案顧問擔任講師,完整介紹 Azure OpenAI Service 和 Azure OpenAI Studio。參與者將透過實際操作,學習如何創建和優化各種情境的提示(Prompt)。同時,瞭解到如何將 Azure OpenAI 服務運用至公司內部實際場域。此外,工作坊也會從中提供最佳實踐案例,讓參與者探索新的解決方案、原型設計和部署方式。

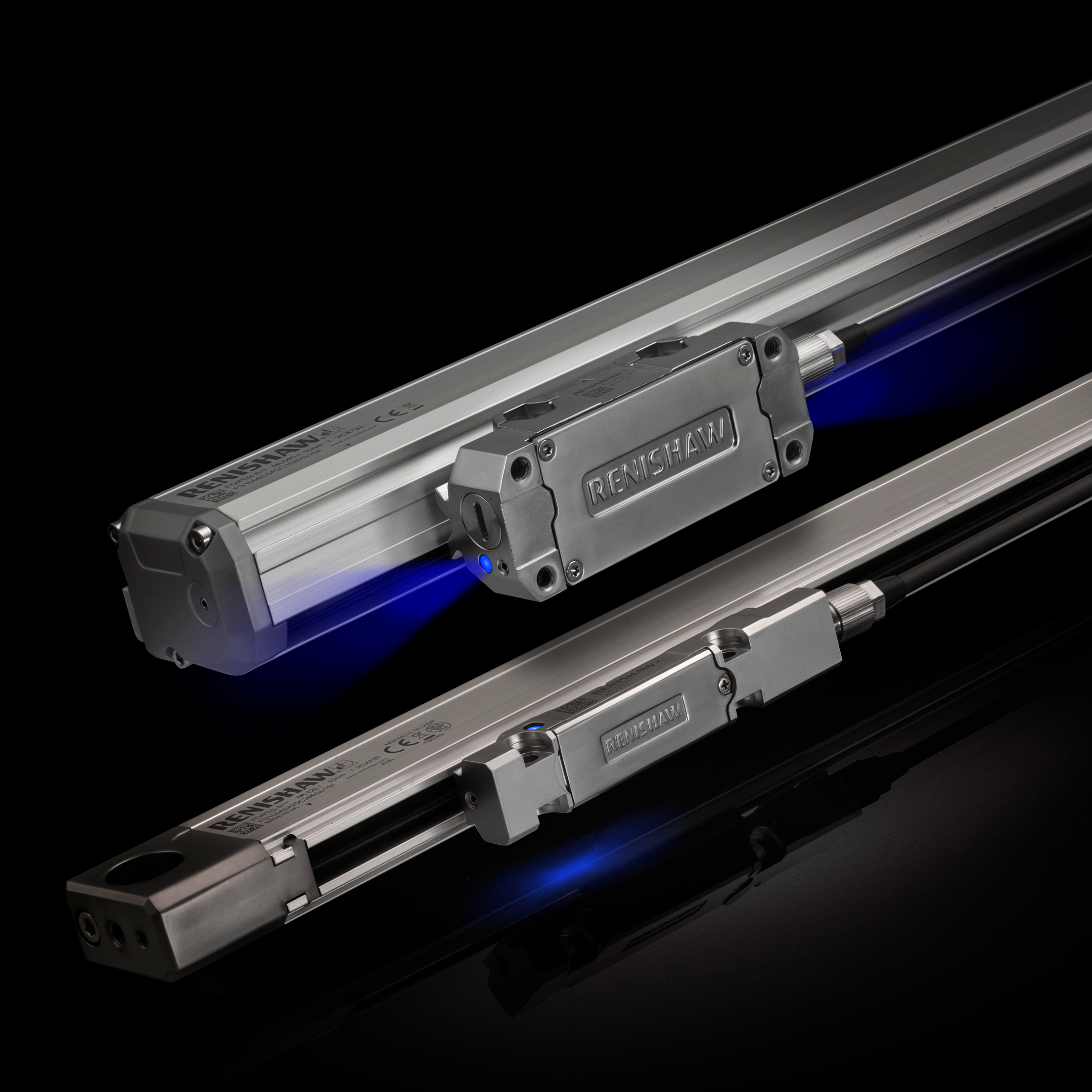

Ametek Taiwan Corp., Ltd.

Product Description :

Autocollimator:The autocollimator is used for measuring angle, straightness, flatness, squareness and parallelism.

MAT:The micro alignment telescope is used for alignment inspection and adjustment in machine tool and ship industries.

Talyvel:The Talyvel electronic level is used for measurement and adjustment, such as: straightness of machine tool guideway, flatness of granite platform.

Clinometer:Precision in angular measurement, checking and setting with 360° range.

Prism Checker:Automatic Prism/Polygon measurement system.

YEONG CHIN MACHINERY INDUSTRIES CO., LTD.

Product Description :

NFX400A is designed especially for small, complex high-quality parts mainly for aerospace, automotive, medical, job shop and die & mold applications

■ Extra wide column and base design to ensure best support and cutting rigidity.

■ Increased tool life by cutting with belly and edge of the tool

■ Reduce fixture error and improve workpiece loading and uploading time

■ Greatly reduced non-cutting or setup waiting time

■ Saves manufacturing cost with reduced fixture and electrode costs.