Theme

Digital Transformation

Green Transformation

HEIDENHAIN CO., LTD. (TAIWAN)

Product Description :

Linear encoders are indispensable for machines with high demands regarding positioning accuracy and machining speed. Linear encoders directly and immediately measure the actual position of the feed axis. This makes it possible to eliminate a number of potential error sources: Positioning error due to thermal behavior of the recirculating ball screw

, Reversal error, errors due to deformation of the drive mechanics by machining forces, kinematic errors through pitch error in the recirculating ball screw.

VICTOR TAICHUNG MACHINERY WORKS CO., LTD.

Product Description :

.Turning & Milling in one set-up

.Y-axis travel 260 mm (10.2")

.Max. turning dimension Ø500 x 1075 mm

.Turning spindle 4200 rpm / 15 KW with 8” chuck for Vmt-X200, or 3500 rpm / 22 kW with 10” chuck for Vmt-X260

.Milling spindle 12000 rpm / 22 kW

.with HSK-T63 / A63 tooling

.ATC-40 tools

INNOSERV FA INC. TAIWAN BRANCH (BVI)

Product Description :

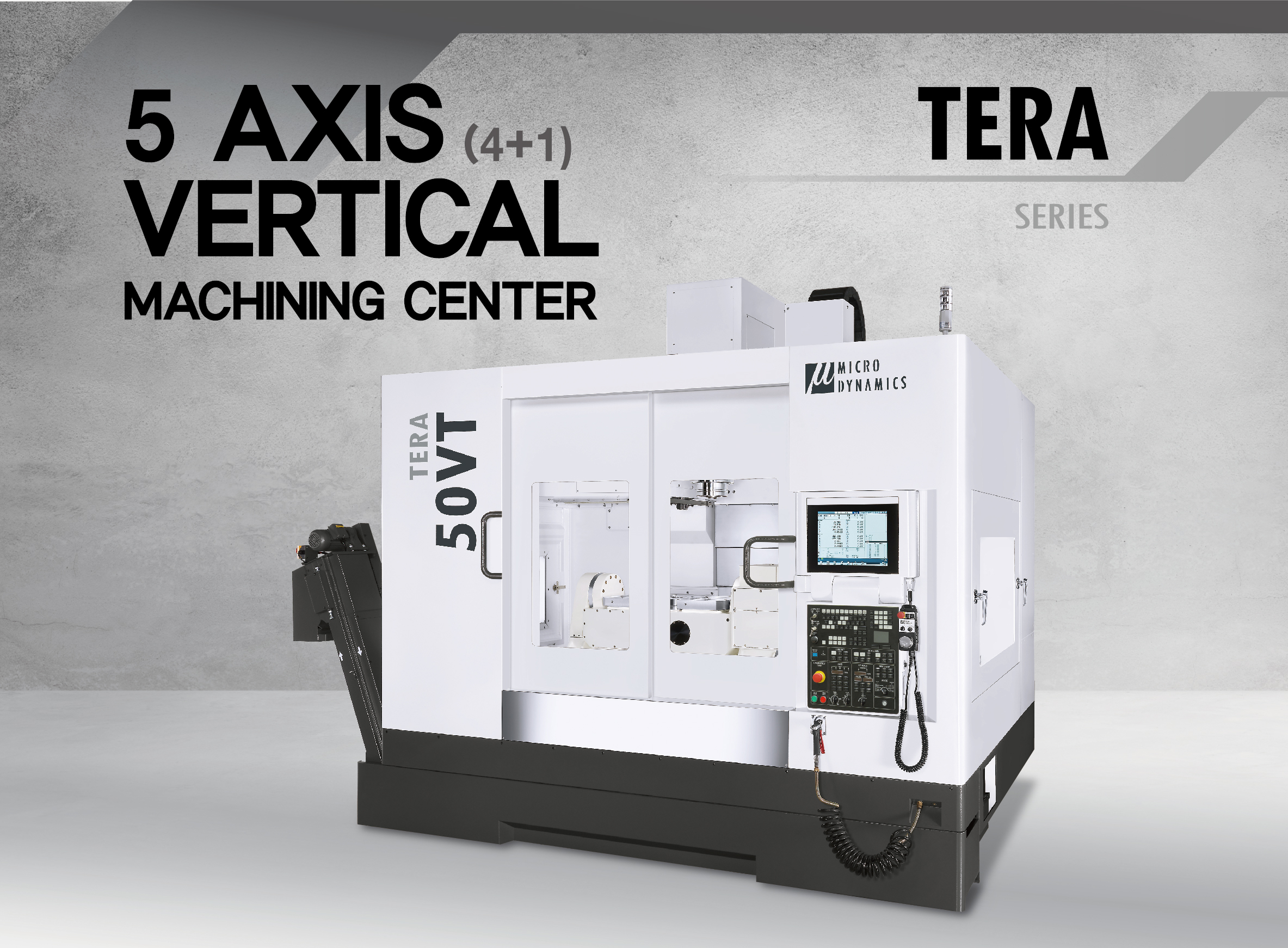

Micro Dynamics Vertical Machining Center Line opens a new era in multi-purpose and versatile machining centers. Compact, durable, powerful, strong and accurate, the MEGA/TERA Series starts a revolution in the market: the smallest C-frame machines provide powerful and precise results for manufacturers of dies and molds, aerospace, automotive, semi-conductor, job shops and general machine sectors.

The MEGA/TERA Series has been designed with the latest in technology being utilized throughout the machine with productivity in mind. From its EtherNet/IP architecture for easy automation and integration into systems and cells, to its Motion Control for fast and smooth operations used in all industries, the MEGA/TERA Series has quickly become one of the industries leading machine tool lines of Vertical Machining Centers.

The MEGA/TERA Series has been refined through years of research and development of new technologies that greatly enhance the machines for the rigors of the Mold and Die industry.

All series are equipped with

■ 15,000 rpm Built-In Spindle

■ Thermal Compensation (DYPEC)

■ Micro Dynamics HMI

MING YANG MACHINERY CO., LTD.

Product Description :

The model MTY 51/65 is equipped with a dual spindle double turret and double Y axes. The machine is combined with FANUC 31i PLUS for simultaneous control on triple tool systems. The machining support two turrets for one spindle and one turret for two spindles at the same time. In other words, each process will collaborate with three tools. Mostly, the machine improves 50% efficiency.

ACROW MACHINERY MFG. CO., LTD.

Product Description :

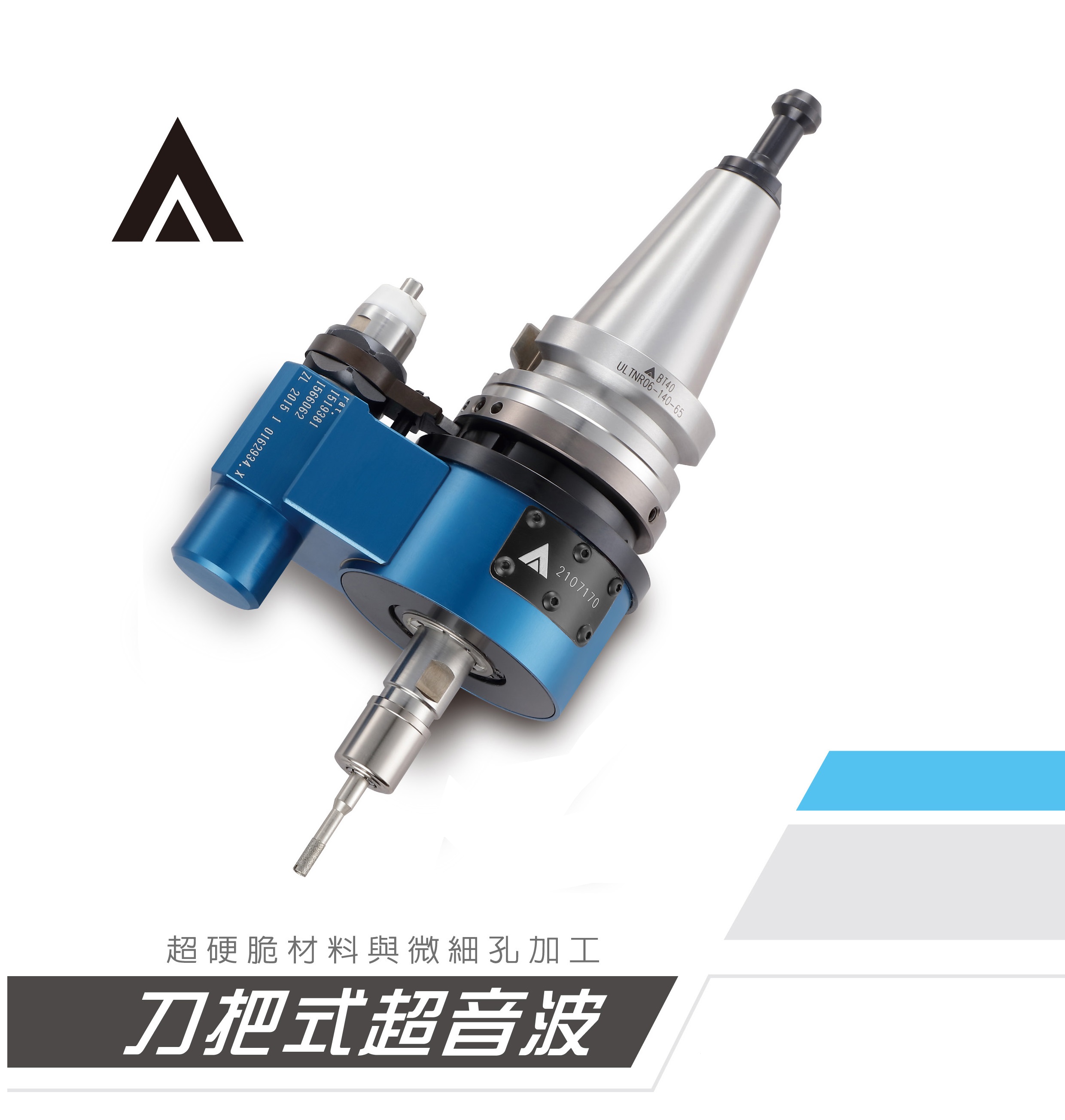

For Hard brittle material and micro holing drilling / Toolholder support for coolant function /

Clamping accuracy under 5 micro with the spring collets/ No need for special machine /

Easy to operate and install /

Reducing cutting resistance /

Improve surface roughness

RAISE PRECISION CO., LTD.

Product Description :

Capacitive switches with touch sensor technology

The first capacitive switches with touch sensor technology from CAPTRON were used in 1994 for public transportation. Today, CAPTRON offers a wide range of capacitive SENSORswitches for various industries and applications where unconditional reliability, durability, comfort and design are required.

If necessary, SENSORswitches from the standard range can be tailored and modified optically and technically to meet individual customer demands.

Skeye Machinery co.,LTD

Product Description :

The appearance and structural dimensions of the YRTS high-speed turntable bearing (referred to as YRTS turntable bearing) series are the same as the YRT series, but the internal structure is different from the YRT series. This determines that the YRTS turntable bearing series has a higher limit speed than the YRT turntable bearing series. The friction torque is lower and more uniform than that of the YRT turntable bearing series. Therefore, this series can be selected for applications that require relatively low friction but relatively high speed, such as bearings used for shafts driven by direct drive motors.

The radial rollers use nylon retainers, so that the YRTS bearing has the characteristics of high limit speed and low and stable friction torque, so this kind of bearing is suitable for engines with torque.

SUN FIRM MACHINERY IND. CO., LTD.

Product Description :

Machines are equipped with a product visualization. This remote monitoring system can check the life of machines' parts, spindle servo axis and tool. This device can report potential problems in advance and solve them, reducing cost and preventing waste of operational time.

Our specially designed spindle accommodates up to two sets of mandrels at the front and back, which is perfect for processing long tubes or bars. The turret is designed to fit the rigid platform-type rail structure, providing the best balance between high cutting resistance and processing efficiency. The design of the body structure is complete and the interface is taken into account in advance. It can support the robot arm, the automatic power system as well as the power turret and lead to a more efficient treatment, bringing us win-win benefits.

Go power machinery CO.LTD

Product Description :

Gutian horizontal cam fix-axis rotary table has internal cam roller transmission mechanism.

There is backlash-free rolling drive between cam and needle bearings pre-load, no sliding

friction or backlash. Its positive reverse motion has high repeatability accuracy without the

need for periodic calibration and adjustment. Its accuracy is not affected by rising

temperature. Improving the quality of multi-axis machining parts can greatly reduce defective

rate of machined parts.