Theme

Digital Transformation

Green Transformation

KINGYOUP ENTERPRISES CO., LTD.

Product Description :

The INNOVATEST hardness tester covers various testing methods such as Rockwell, Vickers, Brinell, and Knoop, and all products comply with ISO and ASTM standards. In ISO 17025 accredited laboratories, you can confidently use the calibrated and certified INNOVATEST hardness tester. We have already provided advanced material testing solutions to numerous international machinery, aerospace, automotive manufacturers, and research institutions.

The INNOVATEST multifunctional hardness tester offers an extensive range of testing forces and methods, providing users with a user-friendly and convenient testing experience. The equipment is suitable for a wide range of material testing and applications.

YOKE INDUSTRIAL CORP

Product Description :

1. Size from M8 to M48 to fulfill your demand

(M8 ※ 0.3t _ M64 ※ 12t)

2. Design Factor 4:1, Working load limit could be up to 32 tons

3. Lifting point is made by forged alloy steel, quenched and tempered

4. 360 degrees rotation to avoid traditional eye bolt bending.

5. Light weight, High Performance, easily for using

Deliver with test certification to guarantee your safety

HO CHEN MACHINERY & ELECTRIC IND. CO., LTD.

Product Description :

X axis travel:

Single movement: 1125 mm (44" )inch

Dual movement: 560 mm (22") inch

YZ axis travel 700x500 mm (28"x20") inch

Work table: 1850x850 mm (73"x33") inch

Max. Workpiece: 2800x1400x700 mm (110"x55"x28") inch

Max. Workpiece weight: 5800 kg

Max. electrode weight: 400 kg

Machine net weight:8350 kg

Oil level: 110-550 mm (4"-22") inch

Packing size(LxWxH): 5430x4600x3090 mm (214"x181"x122") inch

Work Table to platen: 700-1200 mm (28"-47") inch

Filter: 4

Paper filter:8

Capacity:3400 Liters

Machine Features

> Windows CE controller

> A dialog window with picture description.

> Special repaired frames to quicken the maintenance speed.

> Close-loop design of digital feedback on three axes of the machine significantly increases positioning precision and ORBIT-CUT machining accuracy and efficiency.

> Simple operation interface.

> Common function keys are located on the operational panel for direct use.

> Hot key setting.

> ATC (automatic tool change) and C-axis 360° index can be installed; the process of coarse machining to ultra-fine machining can be completed at one time.

> Dialogue diagram provides various hole-expanding modes such as quick search of edge, centers and datum marks.

> Rich color graphic (the same resolution as a PC screen).

> Automatic multi-step machining (coarse, medium coarse, medium fine, fine, superfine)—up to 10 steps.

> Unlimited number of machining conditions can be saved as machining archives. Each set of machining conditions can be edited, modified or stored. They are easy to edit and easy to find.

> Automatic origin search and multi-point coordinate memory capability.

> 1/2 design capability, ARC automatic discharge waveform detection and automatic adjustment.

> Automatic center position detection, automatic compensation, search of hole center and deepest point; fixed hole machining (cyclic mode, independent mode), which is suitable for different machining conditions; Radial, circular, square, linear (vector), coning, 45° hole-expanding machining.

> Three-axis beeline, two-axis arc, three-axis helix.

> Chinese/English versions interface, metric/British system switch and Z-axis quick up, quick down, slow up and slow down capability.

> Lateral machining, three axes, six directions (plane rotation).

> All alarms describe the source, date and exact time of problem occurrence.

> Optical scale is applied for close-loop position control, enabling extreme position for machining.

> Automatic editing—settings can be done according to type of material, work piece size, machining depth, one side die clearance, final current and rate of electrode wear.

> CNC models possess conventional capability of consistent level of energy discharge, achieving stable and rapid machining and smooth high quality on machining surface while the rate of electrode wear is still low.

> Monitor page indicates machining path and orbital pattern in use.

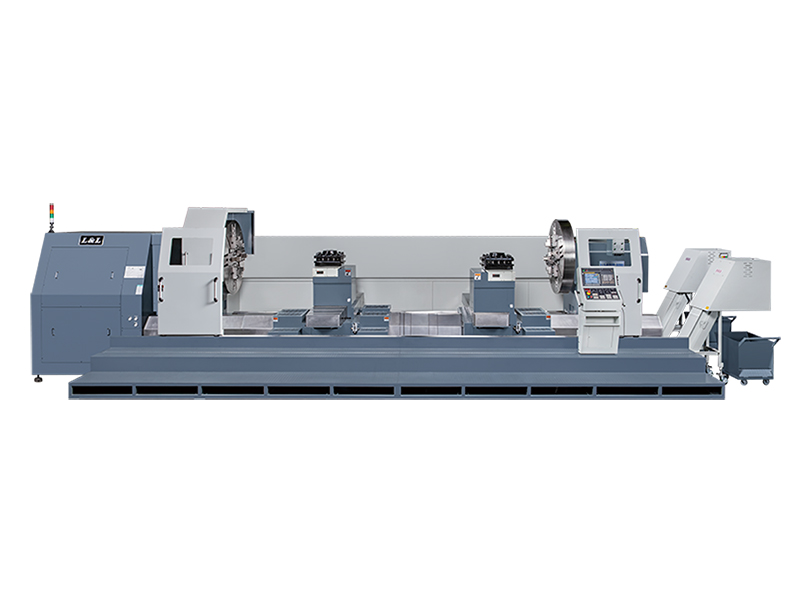

L & L MACHINERY INDUSTRY CO., LTD.

Product Description :

Smart heavy-duty multi-axis composite cutting machine, LLS-M, for the target industry market (oil industry, aerospace industry, steel industry and rubber and rubber industry), achieved ALL Processes In One Machine to reduce the clamping and shortening process, with precision and life management The intelligent machine, constructing the machine information management platform and man-machine management interface, integrating the computer numerical controller, the smart set-top box and the cloud product life cycle database, providing relevant data and data through artificial intelligence calculation analysis and application, reaching the machine Accuracy and life and performance improvement, and applied to the virtual reality pre-sales service system, the use of the real-life expansion after-sales service system to build a smart mechanical value service chain.

Administration for Digital Industries, moda

Product Description :

"Tukey is a No-Code AI platform designed to empower the manufacturing industry with AI solutions, assisting businesses in making optimal decisions in real-time. The key features of Tukey include user-friendly interfaces, easy scalability, and customizable development.

With a friendly operating interface, users can effortlessly create, adjust, and continuously manage AI models. Additionally, users can access custom dashboards through Tukey's extension modules.

Tukey excels in handling factory IoT data, ERP data, and CRM data. Through Tukey's drag-and-drop data extraction, automatic data preprocessing, and parameter adjustments, users can independently complete AI applications. After deploying their self-built artificial intelligence models, users can utilize Tukey's API to create their applications, such as integrating with BI tools or issuing anomaly notifications."

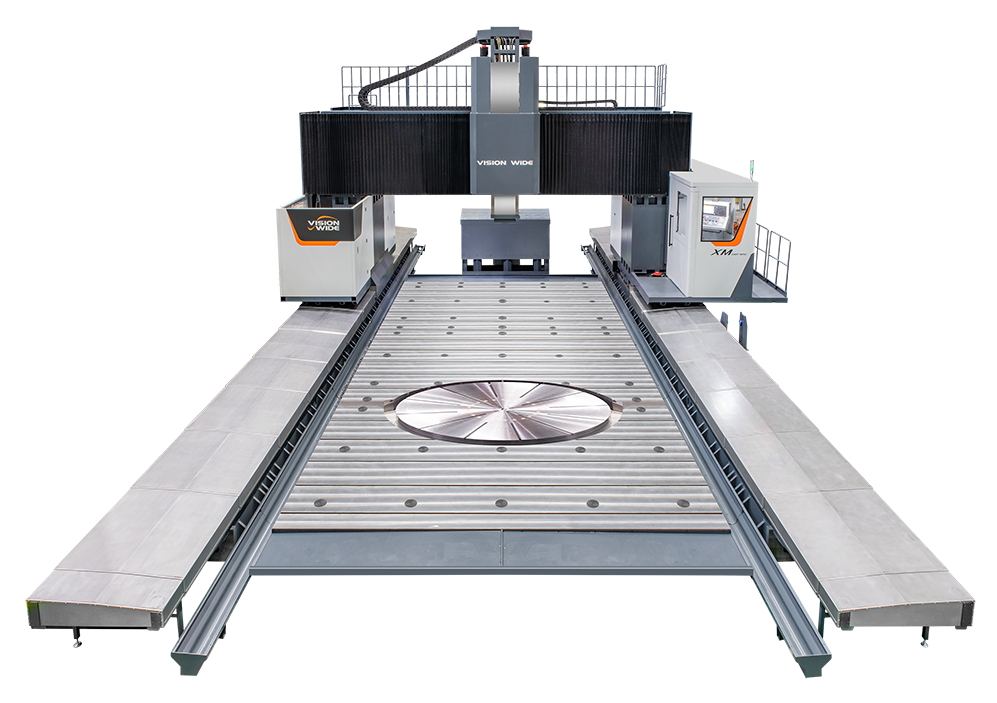

VISION WIDE TECH CO., LTD.

Product Description :

High Performance and Wide Application

XM series moving column machining center is a product developed for the machining needs of large-scale precision machinery, electric power, wind power, energy, petrochemical, transportation... and other equipment. It has:

Huge workpiece machining space: For precision machining of various types of structural parts, it can provide super large XYZ axis machining space.

• High-precise positioning: The high-standard geometric accuracy and positioning accuracy capabilities of the whole machine enable large-scale precision machining

• Heavy cutting capacity: Provide a variety of high-rated torque spindles to meet the processing and cutting capabilities of various materials.

• Fully automatic multi-face machining: This moving column machining center can be matched with various automatic attachment heads for high tangential speed mold surface machining and various types of precision parts complex angle machining, with excellent tool tip point error automatic correction function, and automatic additional head and tool exchange function, it can realize fully automatic machining performance.

• Milling and turning compound multitask: This moving column cnc milling machine can be equipped with a high-torque and high-speed vertical turning table to realize milling and turning compound automatic machining.