Theme

Digital Transformation

Green Transformation

CHANGHUA CHEN YING OIL MACHINE CO., LTD.

Product Description :

1. CEN03 type is without timer (also could be controlled by Programmable Logic Controller) and has to work with volume distributors. With CAB or CBB type volume distributor, oil will feed during operation time. With CDB or T type volume distributor, oil will feed during interval time.

2. The discharge volume is fixed. The lubrication points of volume distributor supply a fixed flow of oil.

3. It has a spark-eliminator inside to prevent the sparks producing when the electric current is running. The spark-eliminator can avoid PLC (Programmable Logic Controller) being interfered.

4. CEN03 type has a pressure switch device and been set up as 8kg/cm2, which assures the oil volume of lubrication point and check if the piping works normally. The standard specification is NC (Normal Close) contact, which means if the pressure is abnormal, it will have signal. NO (Normal Open) contact is available on request.

5. It has a float switch that can detect the oil volume. When oil is lower than the minimum level, the float switch will automatically send a continuous signal.

6. It has a pressure gauge where an operator can check the pressure easily.

7. Do not press the force feed-oil (F button) more than three minutes in order to avoid overloading. When the temperature reaches 100℃, the sensor will be on to stop the motor continuing running about 5 minutes.

8. It can be used for the machines requiring strictly rationing oil flow. It is usually used for such as processing machines or projecting machines.

CLAMPTEK ENTERPRISE CO., LTD.

Product Description :

Clamptek’s CLF5H series designed with connecting rod structure which can operate conveniently. CLF5H series can also reduce the interference with loading and unloading operation, because when CLF5H series is in the unclamping state, it’s clamping arm can be put lower than holding position.

Clamptek’s CLF5H series’ clamping arm is very flexible. By reducing the interference of the surrounding equipment, CLF5H series can save lots of working space.

Clamptek’s CLF5H series equipped with special dust proof design and high sealing, which can prevent the cutting chips and coolant to infiltration. Therefore, CLF5H series can be used in more severe conditions.

Please kindly check the suggested operating pressure as below,

Max. operating pressure: 70 kgf/cm2

Min. operating pressure: 10 kgf/cm2

SHENG YU PRECISION MACHINE CO., LTD.

Product Description :

當我們說UR機器手臂幾乎可能將一切自動化,

我們真的意味著幾乎一切:由裝配到著色,

由螺桿傳動到標籤,由包裝到磨光,由射出製模到焊接,以及其他你能想到的處理工作。

由於UR家族的靈活,機器人手臂在經濟上

更適合小批次和混合產品裝備。

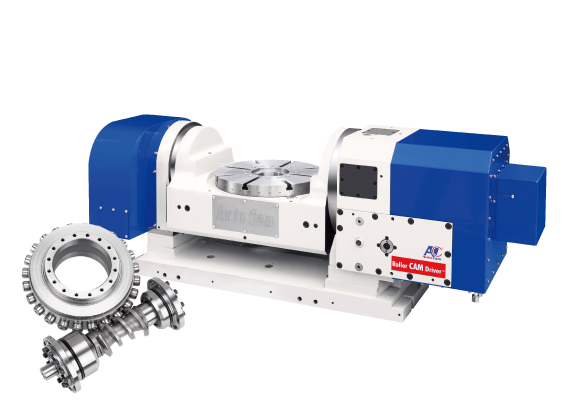

AUTOCAM TECHNOLOGY CO., LTD.

Product Description :

Roller CAM Driver No-backlash NC TILTING ROTARY TABLE.

BLUM PRODUCTION METROLOGY CO., LTD.

Product Description :

• Tool breakage detection

• Tool length measurement

• Machine axes compensation

• Temperature compensation

LITZ HITECH CORP.

Product Description :

1. 集工程集約的車-銑削複合加工,實現<br />一次裝夾多面加工。<br />2. 帶來高精度、高效益,可產生高效益。<br />3. 可更加快速、更加容易實現縮短交期。<br />4. 降低投資人力,能源成本帶來高投資報酬率。<br />5. 可發揮2軸車床+加工中心互為補助的投資效果。

TAIHO TOOL MFG. CO., LTD.

Product Description :

The AERO series is very suitable for high-power equipment above 80KW.

It has a sharp cutting edges and grooves for great efficiency of discharging the chips. The coating is OSG's diamond coating with glossy surface. This bright and smooth surface optimizes the performance of the end mill, especially in aluminum alloy that weldability and lubricity are required.

The 3-short-blade type and center jet type (AERO-ETS, AERO-O-ETS) are corner radius end mills applied to roughing and finishing.

The 3-long-blade type and extra long blade type (AERO-ETL, AERO-EXTL) are corner radius end mills applied to roughing and finishing.

The 2-short-blade type (DLC-AIR-EDS) is corner radius end mills applied to roughing and finishing.

GENTIGER MACHINERY INDUSTRIAL CO., LTD.

Product Description :

- “U” shaped base is one-piece fabricated for maximum stability and rigidity.

- X-axis federate is transmitted through a specially designed rotating nut, it prevents the ball-screw runs out during rotating and makes feed motion response faster.

- Coolant inter ball-screws on three-axis prevent ball-screw deformation, it suppresses thermal growth and thermal displacement on the ball-screw while assuring smooth feed motions and high positioning accuracy.

BUFFALO MACHINERY CO., LTD.

Product Description :

Available with two or six pallets, AXILE’s automated G6 Motorized Pallet Changer (MPC) exchanges raw workpieces and finished parts via a loading bay at the back side of the machine. Operators can load raw workpieces, and inspect and unload finished parts, while machining continues in the vertical machining center 24/7, dramatically increasing operational efficiency.

Freedom and flexibility are core to the design concept, as the MPC solution can be inte-grated upon initial commissioning of the G6 machine, or at a later stage when production capacity expands. And with the MPC-2 (the two-pallet solution), manufacturers can em-brace a Flexible Manufacturing System (FMS), of 12, 24, or 36 pallets total, by integrating one to three machines and two loading stations, depending on the scale required.

With AXILE’s digitalized intelligent automation solutions, manufacturers can eliminate production bottlenecks and ramp up production.