Theme

Digital Transformation

Green Transformation

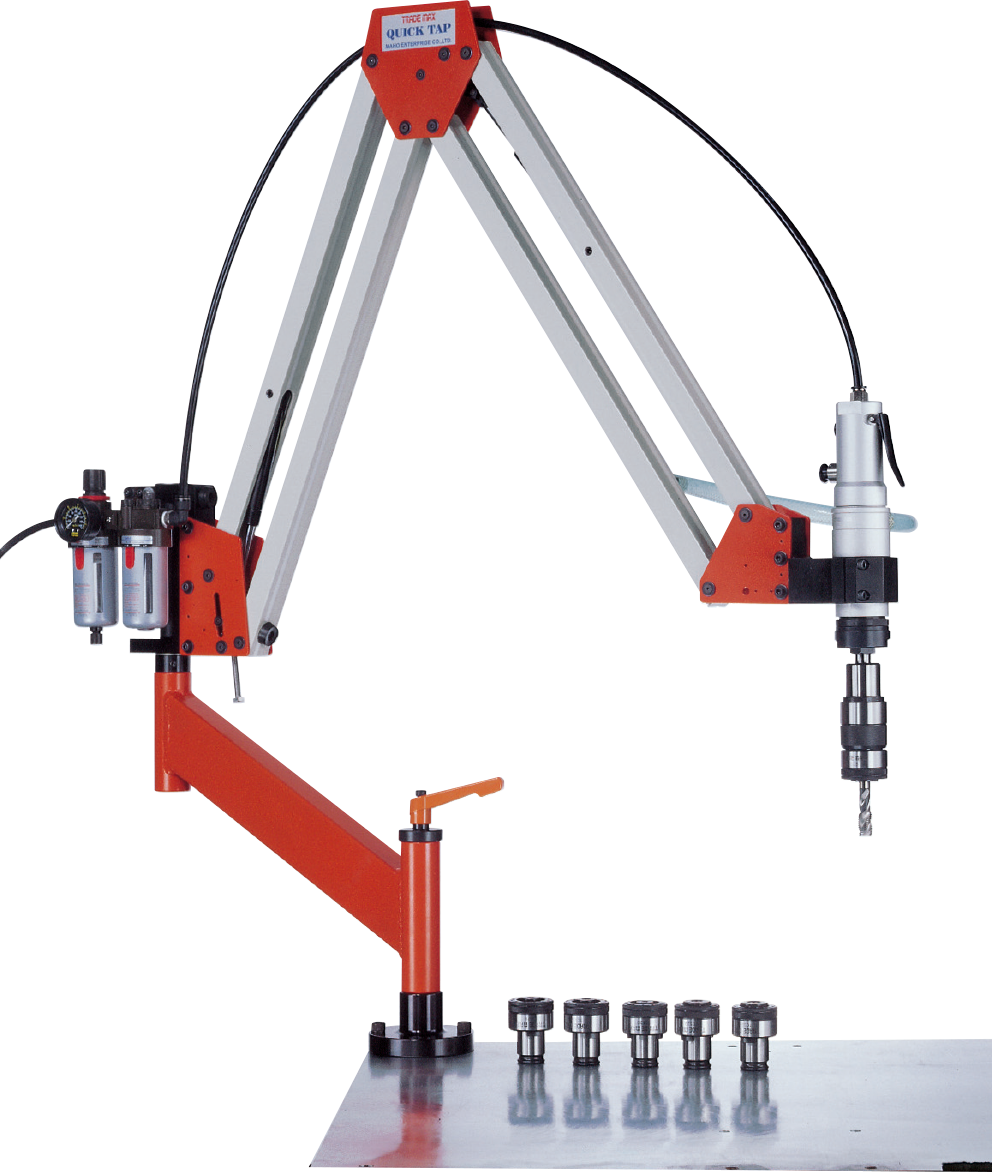

MAHO ENTERPRISE CO., LTD.

Product Description :

Pneumatic tapping machine is suitable for different size taps (from M2 to M27). The arm is equipped with lubricated for life bearings at all swivel points, provides weightless operation through the use of gas counter balance springs and permits the operator to bring the tap to the hole with ease.

Go power machinery CO.LTD

Product Description :

Gutian Cam NC Rotary Table internally adopts cam roller transmission mechanism.

There is backlash-free rolling drive between cam and needle bearings pre-load, no sliding

friction or backlash. Its positive reverse motion has high repeatability accuracy, without theneed for periodic calibration and adjustments. This product is featured with high rigidity,heavy load, high efficiency, and its accuracy is not affected by rising temperature.

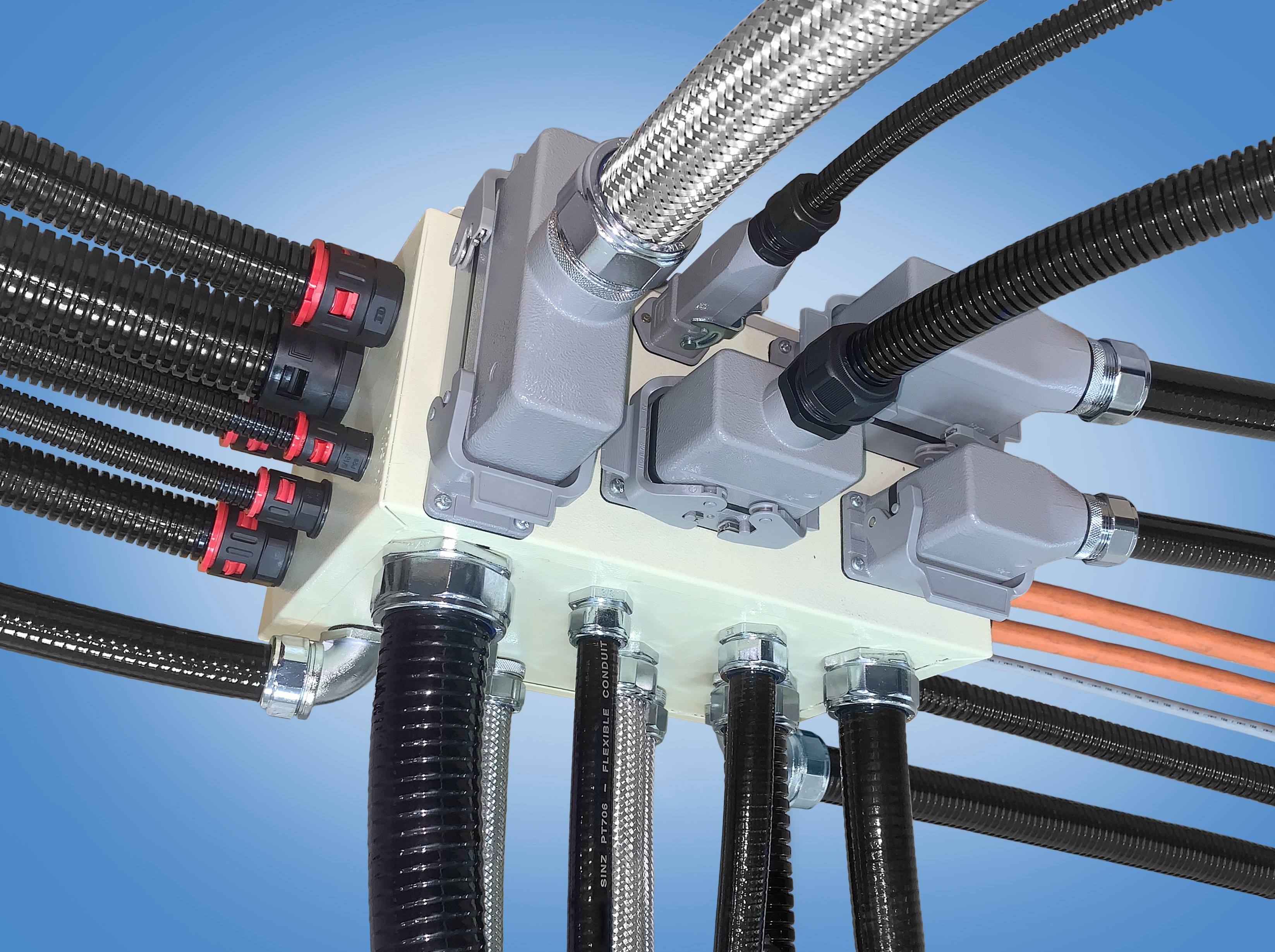

SING CHIUN ENTERPRISE CO.,LTD.

Product Description :

Connector products include:

(1) LIQUID-TIGHT CONNECTORS

(2) COMBINATION CONNECTORS

(3) POLYESTER LIQUID-TIGHT CONNECTORS

(4) THREAD PG & M CONNECTORS ADAPTER (Metal)

(5) MS-PLUG/CONNECTORS ADAPTER (Metal)

(6) SQUEEZE LIQUID-TIGHT CONNECTORS(Hydraulic

clamp is not loose)

(7) METAL CABLE GLAND

(8) POLYESTER CABLE GLAND

(9) MS-PLUG/CONNECTORS ADAPTER (Polyester)

(10) METAL 90° ANGLE-SHAPED WALL-MOUNTED

OUTLET SOCKET

(11) MTR METAL ADAPTER

HO CHEN MACHINERY & ELECTRIC IND. CO., LTD.

Product Description :

X axis travel:

Single movement: 2550 mm (100") inch

Dual movement: 1275 mm (50") inch

YZ axes travel: 850x600 mm (33"x24") inch

※Y axis can be increased to 1300 mm(51") (Option)

※Z axis can be increased to 1000 mm(39") (Option)

Work table: 3100x1600 mm (122"x63") inch

Max. Workpiece: 4100x2050x1250 mm (161"x81"x49") inch

Max. Workpiece weight: 22000 kg

Max. electrode weight: 500 kg

Machine net weight: 29410 kg

Oil level: 110-1000mm (4"-39") inch

Occupy size(LxWxH): 6480x6600x4600 mm (255"x260"x181") inch

Work Table to platen:

600mm Z travel machine: 1138-1738mm (45"-68")

1000mm Z travel machine: 740-1740mm (29"-69")

Filter: 4

Paper filter:8

Capacity:11300 Liters

Machine Features

> Windows CE controller

> A dialog window with picture description.

> Special repaired frames to quicken the maintenance speed.

> Close-loop design of digital feedback on three axes of the machine significantly increases positioning precision and ORBIT-CUT machining accuracy and efficiency.

> Simple operation interface.

> Common function keys are located on the operational panel for direct use.

> Hot key setting.

> ATC (automatic tool change) and C-axis 360° index can be installed; the process of coarse machining to ultra-fine machining can be completed at one time.

> Dialogue diagram provides various hole-expanding modes such as quick search of edge, centers and datum marks.

> Rich color graphic (the same resolution as a PC screen).

> Automatic multi-step machining (coarse, medium coarse, medium fine, fine, superfine)—up to 10 steps.

> Unlimited number of machining conditions can be saved as machining archives. Each set of machining conditions can be edited, modified or stored. They are easy to edit and easy to find.

> Automatic origin search and multi-point coordinate memory capability.

> 1/2 design capability, ARC automatic discharge waveform detection and automatic adjustment.

> Automatic center position detection, automatic compensation, search of hole center and deepest point; fixed hole machining (cyclic mode, independent mode), which is suitable for different machining conditions; Radial, circular, square, linear (vector), coning, 45° hole-expanding machining.

> Three-axis beeline, two-axis arc, three-axis helix.

> Chinese/English versions interface, metric/British system switch and Z-axis quick up, quick down, slow up and slow down capability.

> Lateral machining, three axes, six directions (plane rotation).

> All alarms describe the source, date and exact time of problem occurrence.

> Optical scale is applied for close-loop position control, enabling extreme position for machining.

> Automatic editing—settings can be done according to type of material, work piece size, machining depth, one side die clearance, final current and rate of electrode wear.

> CNC models possess conventional capability of consistent level of energy discharge, achieving stable and rapid machining and smooth high quality on machining surface while the rate of electrode wear is still low.

> Monitor page indicates machining path and orbital pattern in use.

TAIWAN MORE-CASH VILLAGE CORP.

Product Description :

1.Convenient Design

X, Y axis workable professional structure enhanced high-

performance cutting accuracy.

2.Cutting Capacity

Cutting diameter: Ø3~16mm;

Cutting length of work-piece end: 15mmL/max;

3.Patented Radius cutting by Dual-motor driver

The hardened treatment steel is controlled well in virtue of

natural dissipation characteristic, cutting time is greatly

shortened as the work-piece is simultaneously rotated while

cutting.

4.Quick-Work-Changing System

The work-piece is quickly exchanged with prime quality 3-Jaw

chuck system.

5.Cooling System

Dry cooling is able to connect with various pressurized air and

vacuum cleaner achieved perfect cooling effect.

6.Cutting Disc

SD#100 for Carbide, CBN#100 for HSS

7.Optional Grinding Wheel For GS-13 GS-13

SD#100 thickness 5mm, 10mm for Carbide, CBN#100

thickness 5mm, 10mm for HSS

A.Carbide end mill cutting efficiency on GS-13

■ Ø 10mm 4 flute carbide end mill is cut by SD#100 cutting

disc takes 55 seconds.

■ Ø 16mm 4 flute carbide end mill is cut by SD#100 cutting

disc takes 100 seconds.

B.HSS end mill cutting efficiency on GS-13

■ Ø 10mm 4 flute HSS end mill is cut by E60WA cutting disc

takes 60 seconds.

■ Ø 16mm 4 flute HSS end mill is cut by E60WA cutting disc

takes 110 seconds.

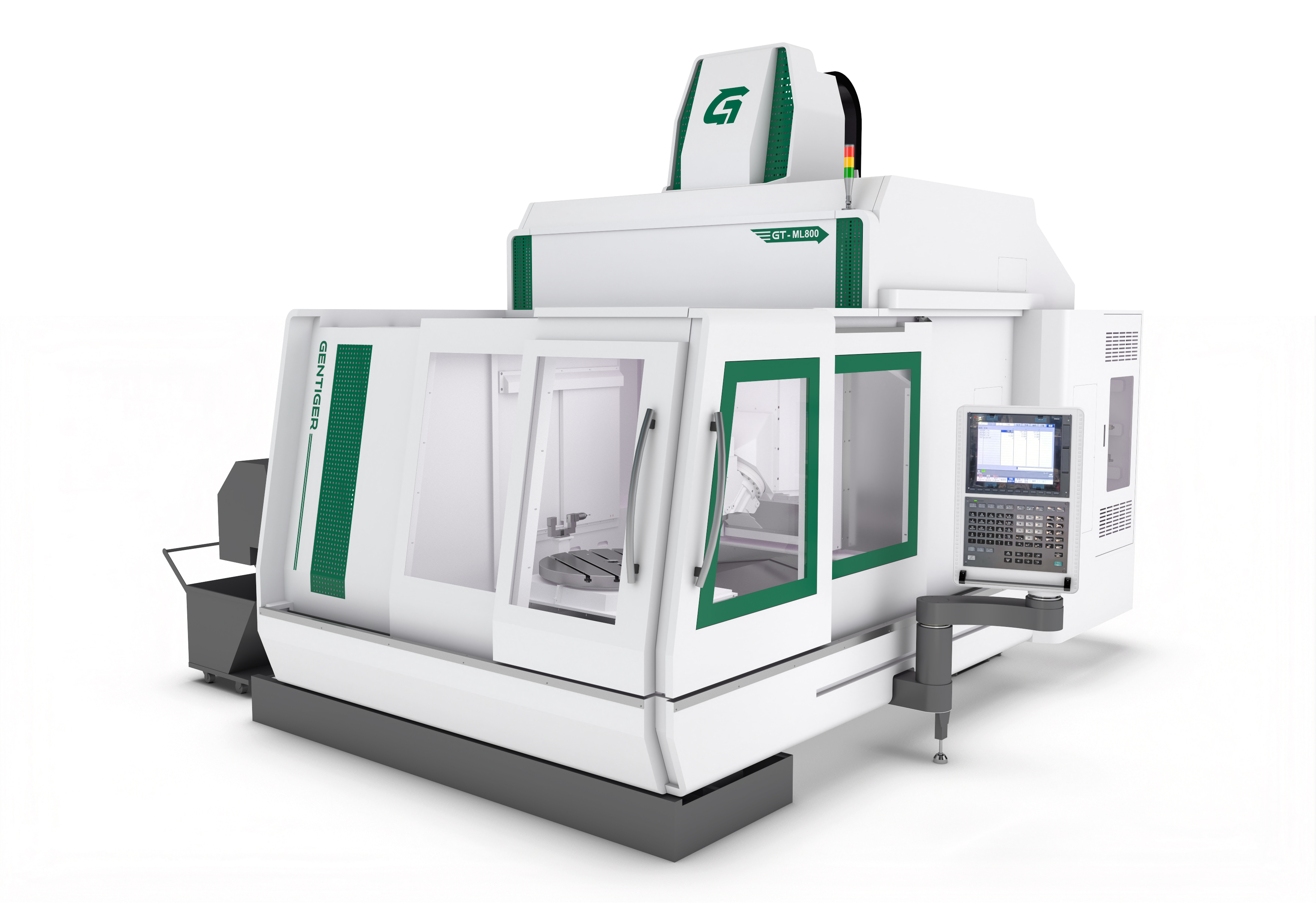

GENTIGER MACHINERY INDUSTRIAL CO., LTD.

Product Description :

• Closed-type double-column structure, it increases structure dramatically increases the structural rigidity of the machine and maintains extraordinary stability at all times.

• Roller-type linear guideway on three axes, it achieves high loading resistance, high rigidity, long service life, low thermal growth, and low noise.

• Three linear guideways on the Y axis, it provides more stable support for the spindle head, which contributes to upgraded stability in machining.

• The 45° vertical horizontal swiveling head is applicable for both vertical and horizontal machining, increasing flexibility in machining applications.

SUN FIRM MACHINERY IND. CO., LTD.

Product Description :

Machines are equipped with a product visualization. This remote monitoring system can check the life of machines' parts, spindle servo axis and tool. This device can report potential problems in advance and solve them, reducing cost and preventing waste of operational time.

Our specially designed spindle accommodates up to two sets of mandrels at the front and back, which is perfect for processing long tubes or bars. The turret is designed to fit the rigid platform-type rail structure, providing the best balance between high cutting resistance and processing efficiency. The design of the body structure is complete and the interface is taken into account in advance. It can support the robot arm, the automatic power system as well as the power turret and lead to a more efficient treatment, bringing us win-win benefits.

RINGIER TRADE MEDIA LIMITED TAIWAN BRANCH

Product Description :

International Metalworking News for Asia (IMNA) print magazines, digital e-magazines, and fully interactive magazine Apps with video links on iTunes and Google Play facilitate technology transfer by providing readers with industry news and trends. For over 10 years, IMNA has been providing readers in Asia practical solutions for improving productivity, reducing cost, and turning innovations into real competitive advantages to advance their operations.

These readers depend on IMNA for detailed technical information for real-world applications Metal Cutting, Lasers, Tooling & Workholding, Software & Control, Metrology, Welding and Metal Forming & Fabrication that can help them develop their business planning and strategies, product quality, process stability, equipment reliability, operator safety and business profitability, as they take advantage of the emerging opportunities from the Asia region.

Our editorial partners include Ringier’s family of Metalworking magazines covering the Greater China and a team of authoritative editorial advisors throughout South East Asia.

For suppliers, International Metalworking News for Asia is an effective multimedia platform which provides the latest information on their products and services. Through a dedicated Metalworking vertical, the industry community can find daily news updates and exclusive online features, videos and reports on major industry events – including live updates from trade shows as they happen – to keep the industry stay informed. Bi-weekly E-newsletters featuring headline industry news, trade show coverage, and analysis and market reports keep you linked to the industry with your latest company information.

GT MARKETING Co., LTD.

Product Description :

Designing Is to Deliver A Better Life Experience

Experience design is a coherent journey of using, from exploration and research, innovative concepts to design implementation, the whole process should be taken seriously. In order to achieve this kind of experience design, GTMC has established a UX design team with talents including user research, information architecture, interactive designers, visual designers, web designers, and front-end engineers. The team is diverse, full of enthusiasm, and also paranoid about design.

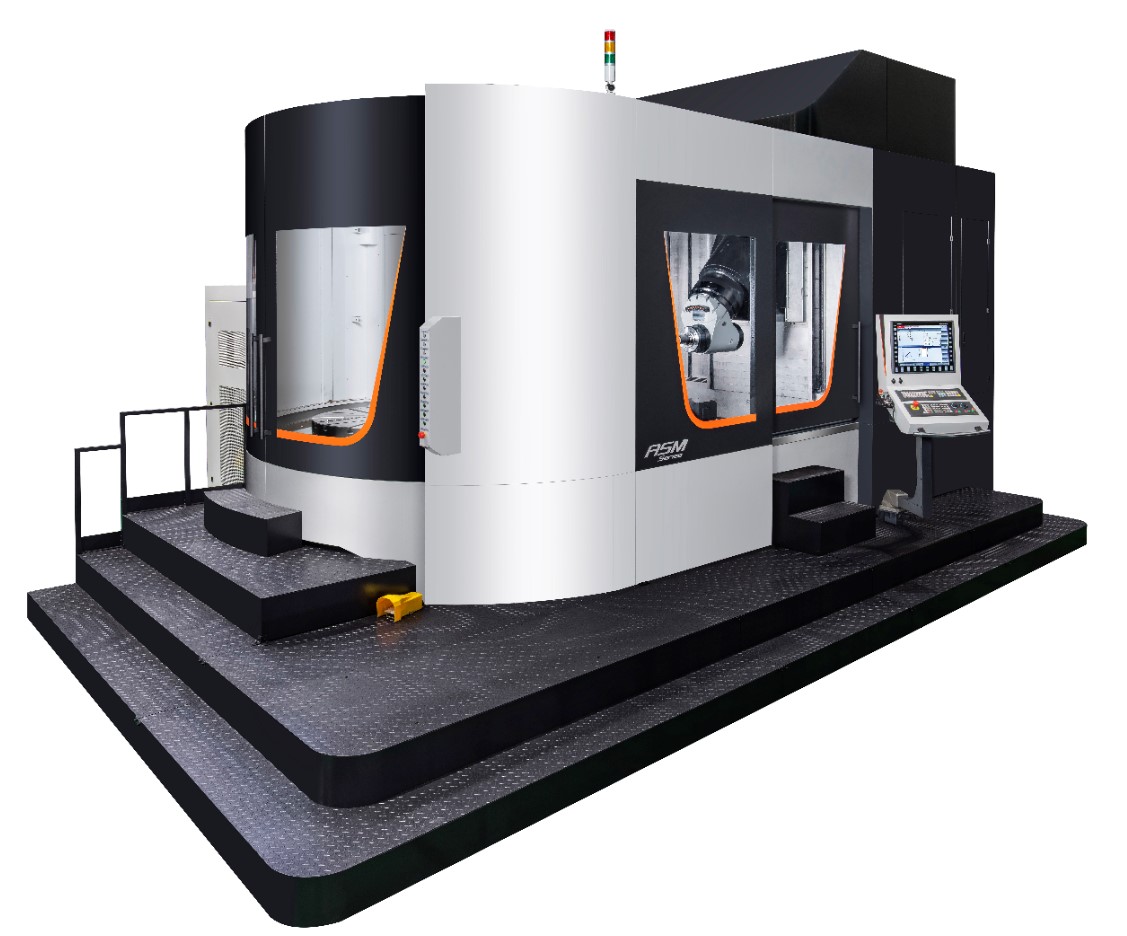

VISION WIDE TECH CO., LTD.

Product Description :

• ASM is the first 5-axis CNC turning and milling machining center of Vision Wide, and it is particularly designed for delicate cylindrical components machining featuring high acceleration, rapid feed-rate and synchronized axes machining, especially for aerospace components, tire molds, turbine blades and aluminum parts.

ASM accessorizes with 5-axis universal head and rotary shafts built-in D.D motor. Through topology analysis, ASM realizes the best distance between tool center point and B-axis transmission

• Positioning P0.006mm

• Repeatability Ps0.0055mm

• Spindle thermal compensation 0.02 mm

• Rapid Traverse 40m/min

• Acceleration 0.3G

• Cutting Feed rate 24 m/min