Theme

Digital Transformation

Green Transformation

HIWIN TECHNOLOGIES CORPORATION

Product Description :

【ESG Sustainable Goal for Motion Control Components】

According to TrendForce research, the green factories will boost the global smart manufacturing market, which will reach $620 billion by 2026. As the concept of ESG sustainability has set off a wave of enthusiasm around the world, HIWIN linear motion components have also continued to focus on intelligent energy-saving innovation, providing simple, safe and modular designs to help customers upgrade from the inside out and embrace the trend of ESG energy saving!

The world’s first Intelligent 4.0 Ballscrew i4.0BS®, together with Intelligent 4.0 Guideway i4.0GW® and Intelligent Single-Axis Robot provide users to monitor health conditions of multiple machines and allow users to plan the production and pre-schedule the maintenance. The function of improving productivity and reducing carbon emission is also in line with the ESG sustainable goal.

-i4.0BS® multi-function sensors design with algorithm, effectively monitor the status of the Ballscrew. The users can monitor machines' conditions anytime.

-i4.0GW® sensor can be mounted on the block according to customers' demand. The system is fully compatible with i4.0BS®.

-The intelligent single-axis robot iSR has a modular design to meet the users' needs in various fields.

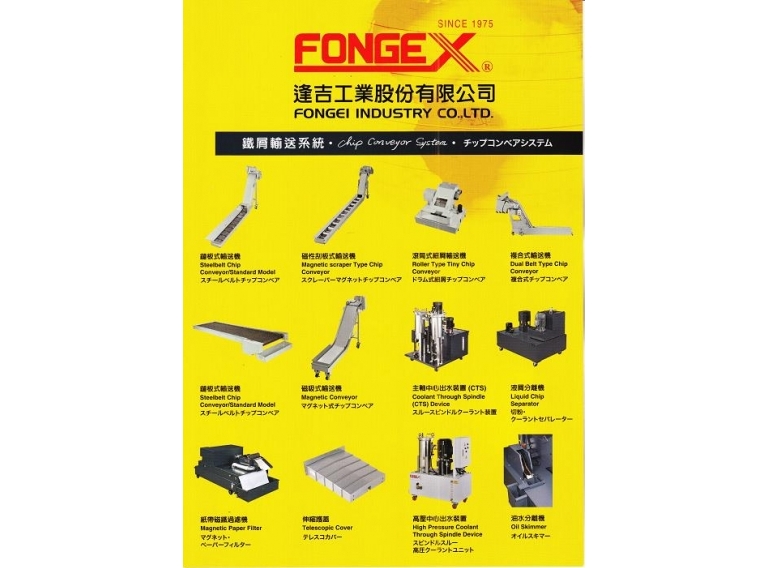

FONGEI INDUSTRY CO., LTD.

Product Description :

Steelbelt Chip Conveyor/Magnetic scraper Type Chip Conveyor/Roller Type Tiny Chip Conveyor/Dual Belt Type Chip Conveyor/Magnetic Conveyor/

Coolant Through Spindle(CTS) Device/Liquid Chip Separator/magnetic paper Filter/Telescopic Cover/High Pressure Coolant Through Spindle Device/Oil

Skimmer

YOKE INDUSTRIAL CORP

Product Description :

•Rotates through 360° and pivot 180°, and simultaneously allows lifting from any direction.

•Manufactured from forged alloy steel, quenched and tempered.

•Manufactured and tested in accordance with EN1677-1.

•Load rated parts are 100% magnaflux crack detected.

•Individual forged parts and cap screw are traceable to Test Certification.

•Bolt are Metric thread (ASME / ANSI B18.3.1M).

•Proof tested to 2.5 times the WLL.

•Fatigue rated to 1.5 times the WLL.

•All YOKE Lifting points meet or exceed all the requirements of ASME B30.26.

•Quick and simple assembly, just a tapped hole is required.

BEST DIAMOND INDUSTRIAL CO., LTD.

Product Description :

Compared to resin bond and metal bond wheels, Electroplated Grinding Tools are noted for relatively large grit protrusion and higher abrasive concentration. This results in very free cutting properties and in high stock removal capacity. Besides, these tools are noted for:

1. Allow special shapes and profile tools to be made at short notice.

2. Cause very little change on wheel shape after used, suitable for precision grinding.

Application and Processing Material for Electroplated Grinding Tools :

1. Internal grinding: Suitable for the internal grinding of carbide and High Speed Steel. The smallest diameter of our electroplating area is 0.3mm so it could be used in drilling for fined ceramics.

2. Jig grinding: Mostly used in fined ceramics processing and precision grinding for quartz. Customized items are also provided to cater your needs. Common grit size is #80~#325, good for rough and fine processing.

3. Touchscreen Processing: Drilling and chamfering for the glass panel of the smart phone and tablet computer. In order to improve work efficiency, we could also combine different grit sizes in the same diamond mounted point.

4. Grinding for Cutting tools: Normal end-mill grinder and drill grinder go with electroplated wheel. Carbide can be ground by diamond wheel and High Speed Steel could be ground by CBN wheel. Bowl-shape wheel with standard specification is also provided, suitable for the grinding of turning tools.

5. Precision grinding: Electroplating can produce wheel of different shapes without deforming it. Therefore, it is suitable for precision grinding or trimming aluminum oxide wheel.

6. Gem grinding: shape grinding for gem, semi-precious stones, shell and jade.

CHANGHUA CHEN YING OIL MACHINE CO., LTD.

Product Description :

1. Fixed amount of oil feeding that can supply the required amount of oil to each lubricating point.

2. There are various choices of discharge volume, 0.1, 0.2, 0.3, 0.4 and 0.5cc per stroke. The discharge volume of each outlet can be different.

3. Each discharge outlet has a detective piston that can detect if the pipe system works functionally.

4. T type 0.5cc can be assembled either NO (Normal Contact) or NC (Normal Close) Contact sensor switch. It also can be set up as NO or NC Contact upon request. When it is set up as NO Contact, it sends signal during the operation time. When it is set up as NC Contact, it sends signal during the interval time.

5. T type volume distributors accumulate oil inside of the distributor and discharge oil during the interval time.

6. T type volume distributors have to work with oil pressure-relief type lubricators. The lowest operation pressure is 8 kgf/c㎡ and the max pressure is 30 kgf/c㎡.

7. The viscosity range of oil is 32 ~90 cSt @ 40℃.