Theme

Digital Transformation

Green Transformation

JEFFER MACHINERY CO., LTD.

Product Description :

This machine comes in a one-piece construction that has been heat-treated to achieve maximum rigidity. The rails are thermal treated and precisely ground to reach hardness of more than HRC 60˚. Furthermore, options are available to adopt rails of various lengths to meet different knife grinding requirements. The machine length can be customized for specific needs from 1,600 to 4,000mm. Rough and finish grinding wheels can be controlled manually and automatically. The minimum grinding wheel downfeed amount is 0.005mm and the spindle is equipped with an automatic cooling system which ensures excellent cooling effect. The SSG-8 employs an automatic lubrication system for smoother operation and longer service life.

SSG-8 Feature :

1. Knife tools movement type.

2. After grinding by coarse wheel and fine wheel, knife

tools can be sharp.

3. Force cooling system on motor shaft obtains better

cooling effect for the knives.

4. Grinding wheel lifting seat is used by ball bearing screw,

it can adjust up and down movement in precision.

5. Water splash guard and coolant tank are made of

stainless steel.

6. Grinding Capacity (Magnetic Chuck) LxW :

2500x200mm

TAIWAN 3AXLE TECHNOLOGY CO., LTD

Product Description :

Feature of product :

The light spot can be adjusted from 0 to 300mm;

Rust removal gun weight 0.7KG

The system monitors the running status from time to time, monitors and collects the running status of lasers, chillers, and control panels;

Light weight, small size, ergonomic design, comfortable grip;

The safety lock touches the light;

The operation is simple and easy to use, and the requirements for operators are extremely low;

Strong anti-interference;

The fully sealed structure has built-in water and air channels;

Safe and pollution-free, low maintenance cost;

The hand-held laser rust removal and cleaning machine adopts the latest generation of optical fiber laser, which has the advantages of simple operation, small appearance and fast cleaning speed. It has an irreplaceable cleaning process in hardware material rust removal and oil removal. Easy to install, control and automate. Simple to operate, turn on the power and turn on the equipment, you can clean without chemical reagents, media, dust and water, you can manually adjust the focus, clean with curved surfaces, and clean the surface with high cleanliness Advantages, can remove resin, oil, stain, dirt, rust, coating, plating, paint on the surface of the object.

RICH SOU TECHNOLOGY CO., LTD.

Product Description :

This machine is an improved model from the Y Rail model, featuring similar functions.

Designed standard with 4-station hanger with two side doors on blasting chamber. To meet your specific production line requirements, additional hangers are available for the entire working environment. Contact us for further details.

Features:

1.The machine employs a PLC controller for continuous cycles of blasting operation.

2.The cycle motions are: the hanging shaft enters the blasting chamber, and then moves to a fixed position at a lower speed. The door closes automatically.

Once the door is closed, the blade starts running automatically, and the machine performs blasting. Once operation is accomplished, steel balls are supplied and the blade stops automatically.

When the blade comes to a complete stop, the door opens automatically. When the door opens to the fixed position, the chain conveyor quickly delivers the nest hanging rod into the blasting chamber, then moves forward at a lower speed to a fixed position.

The door closes automatically and performs the nest cycle of blasting operation.

LEPAO ELECTRICITY MACHINERY CO., LTD.

Product Description :

Features

Double servo system, close-loop control , precision transmission, accurate in location

There are 6 combination of working coordinates in the system, it is convenient to design

programs and process workpiece

Showing location immediately, self-diagnostics and indicating error function

Providing with Start, Stop, manual fine-tuning, returning origin when it finished,

convenient to operate

Editing and modifying working program on controller

Chinese/ English switch , easy to operate

Supporting memory card, or USB to load files

The program can make by CAD/ CAM

Previewing route of working program

Control axis X , Y 6 axis maximum

Collocating with Pipe cutting, driller

8 inches LCD, a concise panel

Can install「Dust Collector 」

YING HAN TECHNOLOGY CO., LTD.

Product Description :

■The specially designed software allows the operator to design the desired graphs on characters with ease, then machining can be conducted immediately.

■By using CAD/CAM software, material can be fully utilized for saving materail cost.

■The automatic height adjustment function enables the focal length to be maintained at a constant status, thus ensuring the consistency of cutting quality.

■3D tilt cutting function (optional) allows multiple tubes to join precisely. The function is also applied for beveled edges welding.

■Small heating area on the workpiece eliminates workpiece deformation problems.

■This machine is equipped with a constant temperature water chiller, enabling the machine to withstand long time continuous running with stable performance.

■The enclosed splash guard can prevent damage to personnel due to the strong laser light.

YING HAN TECHNOLOGY CO., LTD.

Product Description :

■The specially designed software allows the operator to design the desired graphs on characters with ease, then machining can be conducted immediately.

■The automatic height adjustment function enables the focal length to be maintained at a constant status, thus ensuring the consistency of cutting quality.

■Small heating area on the workpiece eliminates workpiece deformation problems.

■This machine is equipped with a constant temperature water chiller, enabling the machine to withstand long time continuous running with stable performance.

■The enclosed splash guard can prevent damage to personnel due to the strong laser light.

■The shortest cutting tail is ≥0 mm.

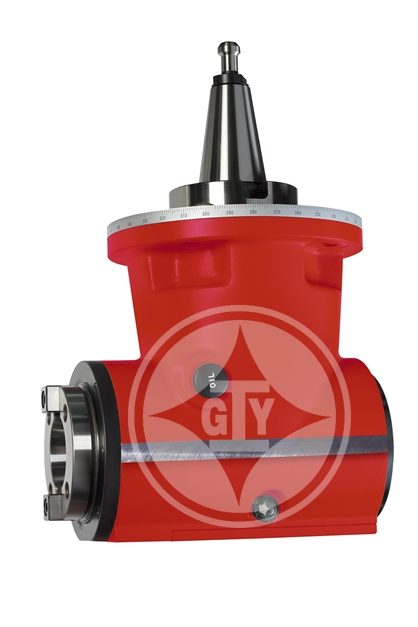

MATRIX PRECISION CO., LTD.

Product Description :

GVP-8040 applies the FANUC controller and high speed grinding spindle, through the Matrix developed intelligent conversations window software, it can flexibly output the required tooth profile and grinding parameters. The machining workpieces include involute gears, large-module hobs and cycloidal gears, the high-efficiency and high precision expressed from the products are equivalent to worldwide top brand’s ones. GVP-8040 is your best choice.

YAW SHENG MACHINERY CO., LTD.

Product Description :

Yao Sheng Machinery Industrial Co. is committed to developing and manufacturing shot blasting machines. We have accumulated rich experience in the field over the four decades. This blasting machine equipped with rails, hangers and hooks, by special design-ensures an even shot blasting and satisfactory treatment in a shorter time. Widely applied in surface treatment in various industrial sectors includes casting, forging, die-casting parts, automobile parts and paint industry, etc.

We set up a R&D division and provide more varieties and customized machines to various industrial sectors. Manufacturing of all products is conformed to ISO standard, and we hold quite a few patents for the machine. Our product is high-functioning. This machine features the mechanism of rotation and spinning, by the special design can greatly reduces blasting time and cost. For all materials that require surface treatment.