Theme

Digital Transformation

Green Transformation

YIH KUAN ENT CO., LTD.

Product Description :

The Plano Milling Head (Gantry Milling Head) are commonly used milling machine heads such as gantry milling machines, boring milling machines, and double-head milling machines. Uses include rough milling, finishing milling, boring holes... and other processing requirements.

The left and right vertical milling heads offer excellent flexibility and adaptability. Their adjustable angles and swivel capabilities enable operators to perform angular milling, drilling, and other complex operations with ease. They are compatible with different milling machines, providing a seamless integration into existing setups or as a valuable addition to new milling machine installations.

1. IK milling heads can upgrade or replacement your existing machine body, milling machine or special machine and also it can bring more stable and high-quality machining benefits for work piece cutting.

2. It is used for mold manufacturing or precision processing.

3. The machine processing for travel is 320 mm. We also provide “No slide” format.

4. This product is used in Gantry (Plano) Milling Machine (vertical / horizontal), suitable for heavy metal cutting.

5. Plano milling head series offer accessory head for you to optional.

It will apply for multi-angle machining to upgrade efficiency and longer machining range.

6. This product of standard motor is 10HP. We also offer 12.5HP for you to optional.

7. Offer pneumatic blade locking device, bearing guide screw, pneumatic leveler for you to optional.

8. There are 10 models in IK Plano Milling Machine Head Series.

SPINTECH PRECISION MACHINERY CO., LTD.

Product Description :

●To meet the demand of processing hard and brittle material, toughness material, and dead soft material.

●To provide the cutting line speed for the tool of micro machining to increase high yield rate of processing.

●Can be used on the existing machine equipment for current machine tool equipment manufacturers.

●To conform the processing needs between traditional milling and ultrasonic.

JEFFER MACHINERY CO., LTD.

Product Description :

This machine comes in a one-piece construction that has been heat-treated to achieve maximum rigidity. The rails are thermal treated and precisely ground to reach hardness of more than HRC 60˚. Furthermore, options are available to adopt rails of various lengths to meet different knife grinding requirements. The machine length can be customized for specific needs from 1,600 to 4,000mm. Rough and finish grinding wheels can be controlled manually and automatically. The minimum grinding wheel downfeed amount is 0.005mm and the spindle is equipped with an automatic cooling system which ensures excellent cooling effect. The SSG-8 employs an automatic lubrication system for smoother operation and longer service life.

SSG-8 Feature :

1. Knife tools movement type.

2. After grinding by coarse wheel and fine wheel, knife

tools can be sharp.

3. Force cooling system on motor shaft obtains better

cooling effect for the knives.

4. Grinding wheel lifting seat is used by ball bearing screw,

it can adjust up and down movement in precision.

5. Water splash guard and coolant tank are made of

stainless steel.

6. Grinding Capacity (Magnetic Chuck) LxW :

2500x200mm

PEIPING PRECISION ENTERPRISE CO., LTD.

Product Description :

*Automatic spindle polishing control.

*Keep the precision of spindle and no damage to spindle body.

*One setting for the maximum convenience of operation.

[After Use]

*Extend the life of cutting tools.

*Increase workpiece accuracy.

*Reduce the spindle vibration and extend the life of spindle.

YATAGHAN ENTERPRISE CO., LTD.

Product Description :

36W/40W is lightweight Single Function Ultrasonic Polisher with affordable prices so it totally fits the requirements of endusers.

The high micro vibration stroke frequency saves time to reach a quality result of polishing and finishing.

Their shaking is much smaller than Air Tools and it is perfect for objects that needs detailed polishing. Like precision molds, electronic molds, PCB boards, jewelry and so on.

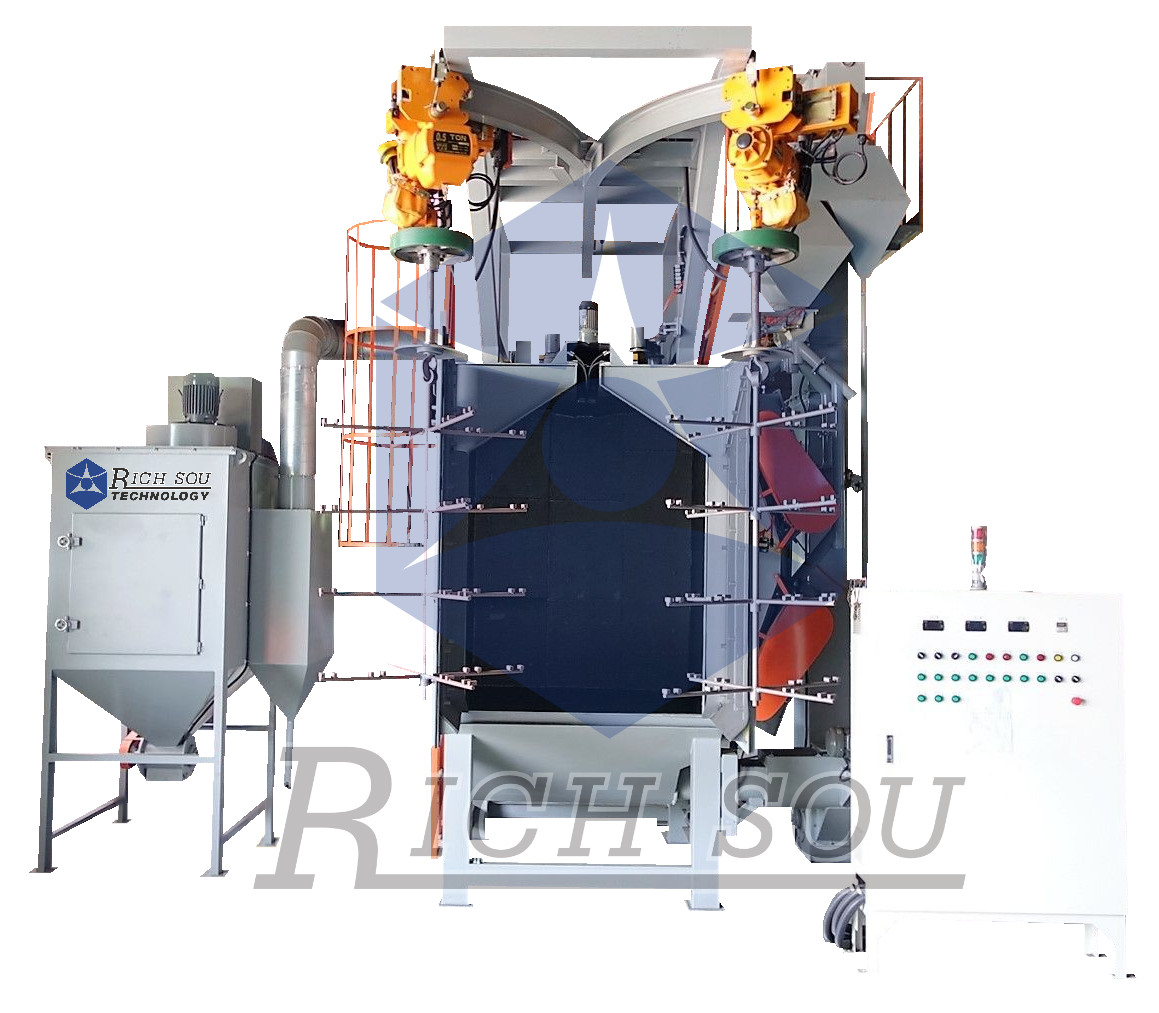

RICH SOU TECHNOLOGY CO., LTD.

Product Description :

The door equipped with PENUMATIC valve safe door opening and closing.

The double bevel mechanism has has rail exchange function.When one shaft is performing parts replacement at the outside for saving time.

Steel shot recycling system: Screw Conveyor is equipped with a sieving screen for separating big grits,which will be emitted automatically.

An air operated steel shot separator built on the top of elevator,fully separates steel shot from heavy grits and dust to reduce the consumption of water resisting parts.

TSYR TZUN INDUSTRIAL CO., LTD.

Product Description :

1.With circuit protection of breaking for motor, once any wire of three phases power source is broken off, this unit could cut off current to motor to prevent motor from being burn out.

2. Drill sleeves、tapping adaptors and borer holder are with rapid adaptors, very convenient for replacement of cutters.

3.Tapping adaptors with torsion control, tap bits are protected from being twisted off.

4.MTM-932ADL comes with drilling force control unit for Auto-feeding:

When drill bit is worn out, this unit will drive feeding intermittently or stop feeding.

Once feeding becomes difficult while making a hole, Please replace a new drill bit or re-sharpen the worn out one in order to protect both drilling tool and machine body from being damaged.

5. MTM-932ADL comes with three intermittent breaking rates for breaking chips :

Choose different feeding rates according to different drill bits and material to perform Auto-feeding operation.

This device can break chips intermittently and discharge them while Auto-feeding is processing, so that chips would not roll on drill bit. Easier to discharge chips.

6. MTM-932ADL comes with three feeding rates for Auto-feeding:

Feeding rates are separately 0, 0.15 and 0.25, please choose suitable rate according to size of drill bit and material of work-piece for drilling.

7. The rotation speed of the MTM-932ADL can be changed quickly during running.

It's very convenient for the operator, and the efficiency is increased accordingly.