Theme

Digital Transformation

Green Transformation

JEFFER MACHINERY CO., LTD.

Product Description :

ASG-800 is an Automatic Carbide Saw Grinder. Original design idea and goal is by the user-friendly, clear operation panel, the PLC numerical control and stores up huge tooth patterns inside it. The machine could grind different kinds of TCT saw blades and can store up common tooth patterns up to 100 groups. It has automatic compensation program to set up grinding wheel compensation. It also can adjust grinding speed and has automatic lubrication system. This is a multi-purpose Automatic Carbide Saw Grinder.

ASG-800 Feature :

1. Using Servo dividing on grinding wheel angle is fast

with high accuracy.

2. It can adjust high and low speed on grinding wheel up

and down movement, which can save working time.

3. Servo used on fixing position for pushing tooth with

precise and fast orientation.

4. With automatically right-left moving on grinding wheel

while working, this can reduce grinding noise and can

sharpen knives well.

5. Grinding capacity : dia.120~800

Saw blade bore diameter: dia. 10~85

PEIPING PRECISION ENTERPRISE CO., LTD.

Product Description :

*Automatic spindle polishing control.

*Keep the precision of spindle and no damage to spindle body.

*One setting for the maximum convenience of operation.

[After Use]

*Extend the life of cutting tools.

*Increase workpiece accuracy.

*Reduce the spindle vibration and extend the life of spindle.

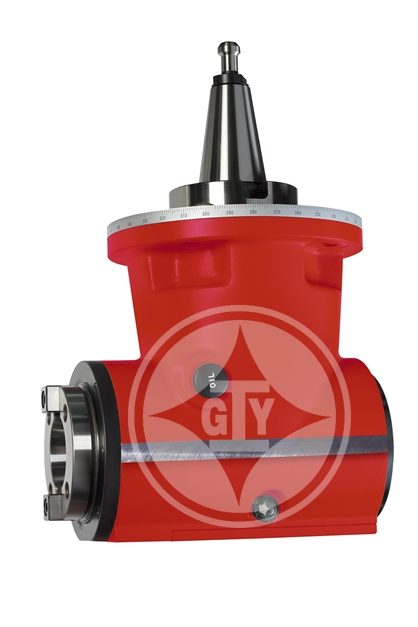

Hantop Intelligence Technology

Product Description :

Tool Holder Spec. provided:

BT30, BT40, HSKA63, HSKE25, HSKE32, HSKE40, CAT40

1. High Speed, high efficiency ultrasonic machining solution for high precision advanced materials machining(can reach 38000 rpm)

2. Plug and Play design for convenient and flexible Installation

3. Effective Intelligent Tracking System for advanced materials machining, finding the suitable resonance between tools and modules

4. Non-Contact transmission Design doesn't limit the high spindle rotation and reduce the impact from cutting heat, enhancing tool life and quality to next level.

RICH SOU TECHNOLOGY CO., LTD.

Product Description :

The door equipped with PENUMATIC valve safe door opening and closing.

The double bevel mechanism has has rail exchange function.When one shaft is performing parts replacement at the outside for saving time.

Steel shot recycling system: Screw Conveyor is equipped with a sieving screen for separating big grits,which will be emitted automatically.

An air operated steel shot separator built on the top of elevator,fully separates steel shot from heavy grits and dust to reduce the consumption of water resisting parts.

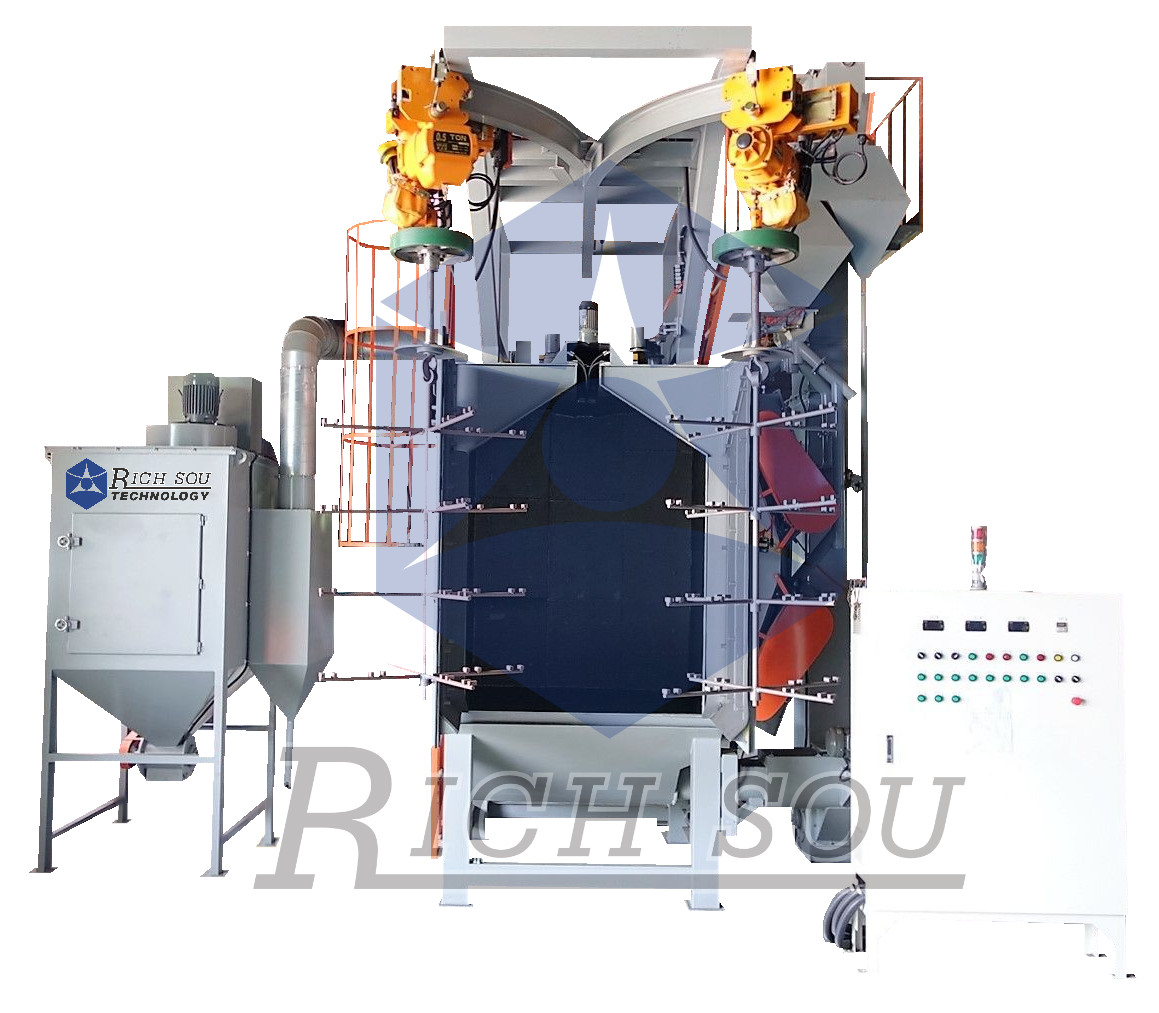

RICH SOU TECHNOLOGY CO., LTD.

Product Description :

This machine is an improved model from the Y Rail model, featuring similar functions.

Designed standard with 4-station hanger with two side doors on blasting chamber. To meet your specific production line requirements, additional hangers are available for the entire working environment. Contact us for further details.

Features:

1.The machine employs a PLC controller for continuous cycles of blasting operation.

2.The cycle motions are: the hanging shaft enters the blasting chamber, and then moves to a fixed position at a lower speed. The door closes automatically.

Once the door is closed, the blade starts running automatically, and the machine performs blasting. Once operation is accomplished, steel balls are supplied and the blade stops automatically.

When the blade comes to a complete stop, the door opens automatically. When the door opens to the fixed position, the chain conveyor quickly delivers the nest hanging rod into the blasting chamber, then moves forward at a lower speed to a fixed position.

The door closes automatically and performs the nest cycle of blasting operation.

TSYR TZUN INDUSTRIAL CO., LTD.

Product Description :

PRODUCT FEATURES

With circuit protection of breaking for motor, once any wire of three phases power source is broken off, this unit could cut off current to motor to prevent motor from being burn out.

Drill sleeves、tapping adaptors and borer holder are with rapid adaptors, very convenient for replacement of cutters.

Tapping adaptors with torsion control, tap bits are protected from being twisted off.

The rotation speed of the MTM-930A can be changed quickly during running.

It's very convenient for the operator, and the efficiency is increased accordingly.

JAR HON MACHINERY CO., LTD.

Product Description :

1.Both cutting TAP and forming TAP are suitable.

2.Fully automatic tapping process. One operator can easily operate several machines at the same time.

3.By using proper master pitch gears(change gears A and B pair), highly accurate thread can be tapped. It is easy and quick to change different size.

4.The length of the tapping stroke can easily be adjusted for high accuracy which is suitable for tapping blind hole parts.

5.It has safe device to monitor the feeding, torque, radial, and clamping to keep TAP's long life and ensure safe working job.

6.It governed by PLC.

7.Long parts or those can't feed in vertical position are suitable.

8.Pre-work parts auto-checking and machine auto-stop if abnormal.