Theme

Digital Transformation

Green Transformation

TSYR TZUN INDUSTRIAL CO., LTD.

Product Description :

PRODUCT FEATURES

With circuit protection of breaking for motor, once any wire of three phases power source is broken off, this unit could cut off current to motor to prevent motor from being burn out.

Drill sleeves、tapping adaptors and borer holder are with rapid adaptors, very convenient for replacement of cutters.

Tapping adaptors with torsion control, tap bits are protected from being twisted off.

The rotation speed of the MTM-930A can be changed quickly during running.

It's very convenient for the operator, and the efficiency is increased accordingly.

MATRIX PRECISION CO., LTD.

Product Description :

GHP-3540 applies the FANUC controller and high speed grinding spindle, through the in-house developed intelligent conversation window software, it can flexibly output the required tooth profile and grinding parameter. The machining workpieces include the involute gears and cycloidal gears, the high efficiency and high precision expressed from the product are equivalent to worldwide top brand's ones. GHP-3540 is your best choice.

YIH KUAN ENT CO., LTD.

Product Description :

The CNC Milling Head can tackle all sorts of critical processes, such as rough milling, finishing milling, boring holes, and much more. It's easily compatible with a number of different machines, like computer gantry milling machines, machining centers, and so on. Don't let small spaces or tight curves slow down your projects - the CNC Milling Head is compact enough to fit even into the most complex of workspaces. Plus its precise performance ensures that you get results exactly how you need them - every time. With the CNC Milling Head you can take your machining to the next level while saving time and money in the process.

1. The IK milling head, which fits your current milling machines and special purpose machines, can take place of your current milling heads and upgrade your machines.

2. This product with gear-type construction is very powerful and can creat a maximum machining efficiency for you

3. Spindle speed change has high and low two stage.

4. This product can be installed to a computer-controlled vertical milling machine and a special purpose machine.

5. This products doesn't include a servo motor or servo controller.

6. The IK CNC milling head series has three kinds of products.

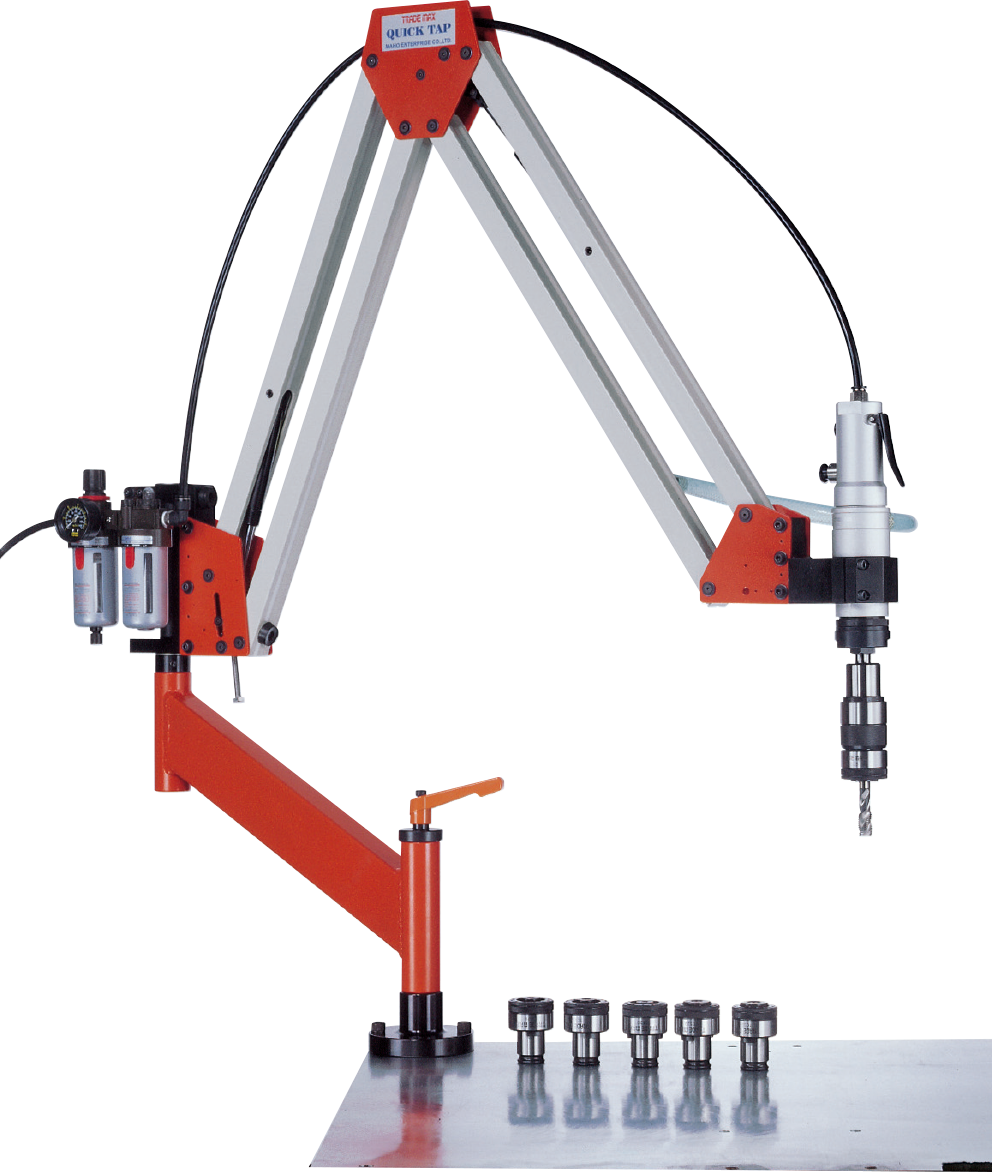

MAHO ENTERPRISE CO., LTD.

Product Description :

Pneumatic tapping machine is suitable for different size taps (from M2 to M27). The arm is equipped with lubricated for life bearings at all swivel points, provides weightless operation through the use of gas counter balance springs and permits the operator to bring the tap to the hole with ease.

RINGTECH INSTRUMENTS CO., LTD.

Product Description :

IFP vacuum cleaning machine can effectively clean any size and structure of complex metal products, great for either large or small amount of cleaning, it is also the best vacuum cleaning machine available for environmental protection and energy-saving! The cleaning cycle is carried out in a complete vacuum environment that the working environment is clean and odourless. During operation, the user can select different options from spray, rotate, ultrasonic, rinse...etc. based on the workpiece. With the cutting edge iFP cleaning technology, overcoming difficult cleaning situations such as cleaning blind holes, slits can be effortless. After cleaning, the chips and residual cutting oil will be separated from the cleaned workpiece, the chips are fully dried and can be collected from the filter; the residual cutting oil will also be separated from water and could be recycled and reused.

Facing the new industry trend and the new future, IFP cleaning machine is your best cleaning choice!