Theme

Digital Transformation

Green Transformation

JAR HON MACHINERY CO., LTD.

Product Description :

1.Both cutting TAP and forming TAP are suitable.

2.Fully automatic machine so a person can operate many machines.

3.Gear-pitch type auto. tapping will get a precise & accurate thread for finished workpiece.

4.It can option to add inverter or use servo motor to control the spindle speed.

4. Especially suitable for light workpiece.

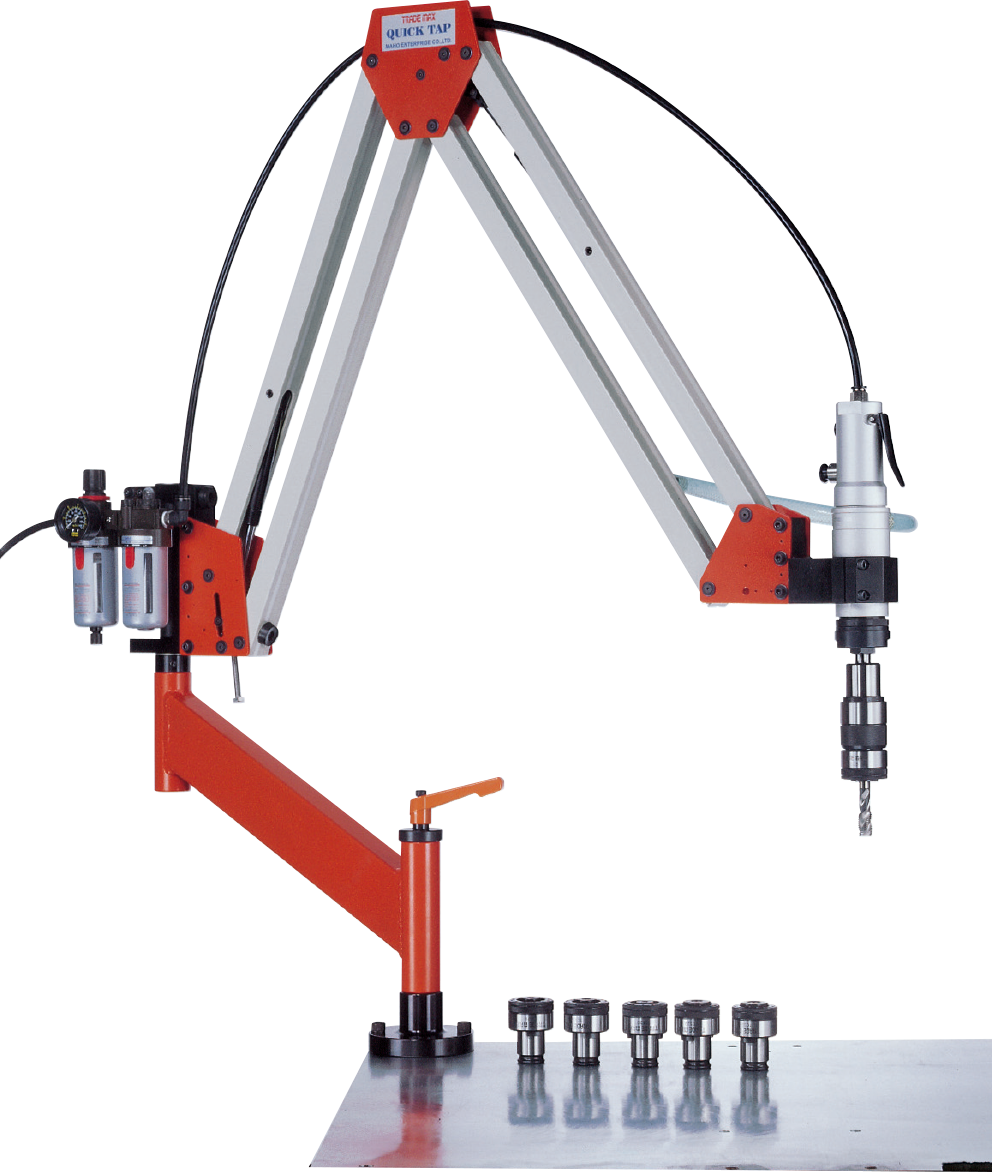

MAHO ENTERPRISE CO., LTD.

Product Description :

Pneumatic tapping machine is suitable for different size taps (from M2 to M27). The arm is equipped with lubricated for life bearings at all swivel points, provides weightless operation through the use of gas counter balance springs and permits the operator to bring the tap to the hole with ease.

Dah Young Vacuum Equipment Co., Ltd.

Product Description :

High Power Impulse Magnetron Sputtering (HiPIMS) is a high-power pulsed power supply system used on magnetron sputtering coating technics. Compared to the traditional DC sputtering system, HiPIMS could generate tens of times higher pulsing current to obtain a ten thousand times higher-density electron plasma. Effectively enhancing the ionization rate to obtain a non-porous, high density crystallinity film at lower coating temperatures.

DAH YOUNG's DYHC HiPIMS series sputtering coater power supply and chamber cavity are designed to provide high plasma density (1018~19e-/m3) and high ionization rate (70~100%), increasing the substrate coating compactness, adhesion flatness and corrosion resistance. The lower duty cycle (<5%) results in a significant reduction in process temperature offering more substrate options on PEN, PET, etc. fiexible substrates.

Please refer to:https://zh-tw.dahyoung.com/

YING HAN TECHNOLOGY CO., LTD.

Product Description :

■The specially designed software allows the operator to design the desired graphs on characters with ease, then machining can be conducted immediately.

■By using CAD/CAM software, material can be fully utilized for saving materail cost.

■The automatic height adjustment function enables the focal length to be maintained at a constant status, thus ensuring the consistency of cutting quality.

■3D tilt cutting function (optional) allows multiple tubes to join precisely. The function is also applied for beveled edges welding.

■Small heating area on the workpiece eliminates workpiece deformation problems.

■This machine is equipped with a constant temperature water chiller, enabling the machine to withstand long time continuous running with stable performance.

■The enclosed splash guard can prevent damage to personnel due to the strong laser light.

TAIWAN 3AXLE TECHNOLOGY CO., LTD

Product Description :

Colour Marking Fiber Laser

Marking Machine

Good for metal materials, All polycarbonate material, plastic Stainless steel and other metal materials surface marking.

Laser safty goggles, Simple Fixture, External red light, Foot Switch.

Taiwan laser marking software

Availavle in 9 languages, English, Traditional/Simplified Chinese, German, Japanese, Polish, Portuguese, Turkish, Vietnamese, Portuguese, Turkish, Vietnamese.

Deep engraving, Metal marking, Serial number, QR code, Data matrix all in one machine.

Auto focus up to 4cm.

3D Rotary up 120º degree.

Hantop Intelligence Technology

Product Description :

Tool Holder Spec. provided:

BT30, BT40, HSKA63, HSKE25, HSKE32, HSKE40, CAT40

1. High Speed, high efficiency ultrasonic machining solution for high precision advanced materials machining(can reach 38000 rpm)

2. Plug and Play design for convenient and flexible Installation

3. Effective Intelligent Tracking System for advanced materials machining, finding the suitable resonance between tools and modules

4. Non-Contact transmission Design doesn't limit the high spindle rotation and reduce the impact from cutting heat, enhancing tool life and quality to next level.