Theme

Digital Transformation

Green Transformation

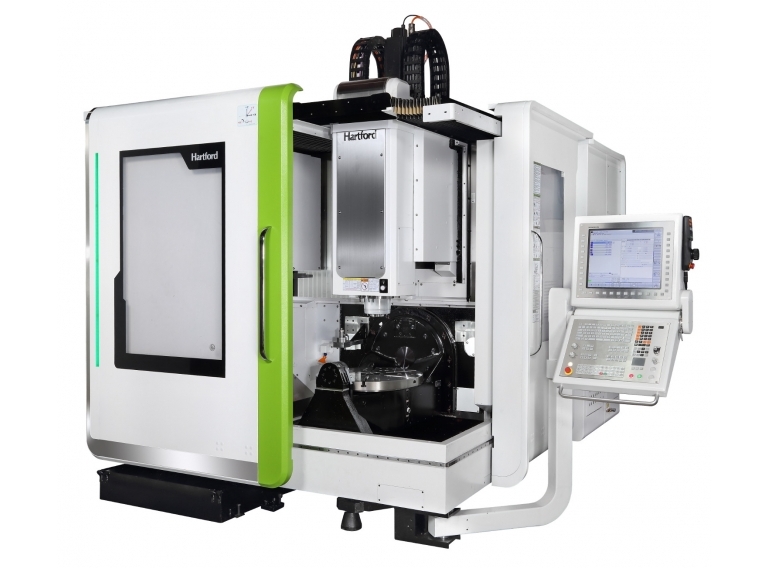

FAIR FRIEND ENTERPRISE CO., LTD.

Product Description :

★Optimized structure configuration

- The base and column are structured as one-Piece casting, which eliminates possible tolerance of the jointing interface.

- Box-opstructure casting and optimal span realize exceptional rigidity and stability.

★Overlapped Axes with 2 Rotating Axes

- Axes of linear movement and rotation are separated so that during 5-axis machining, curve tolerance or error can be controlled and adjusted rather easily.

★3 Axes Motion Area Partitioned Processing Area

- Effective In addition to space chips removal, promoting Antifouling capability, optimal span realize exceptional rigidity and stability.

★Chip removal function

- Forming one large funnel chips off, high performance chip removal

YEONG CHIN MACHINERY INDUSTRIES CO., LTD.

Product Description :

NFX400A is designed especially for small, complex high-quality parts mainly for aerospace, automotive, medical, job shop and die & mold applications

■ Extra wide column and base design to ensure best support and cutting rigidity.

■ Increased tool life by cutting with belly and edge of the tool

■ Reduce fixture error and improve workpiece loading and uploading time

■ Greatly reduced non-cutting or setup waiting time

■ Saves manufacturing cost with reduced fixture and electrode costs.

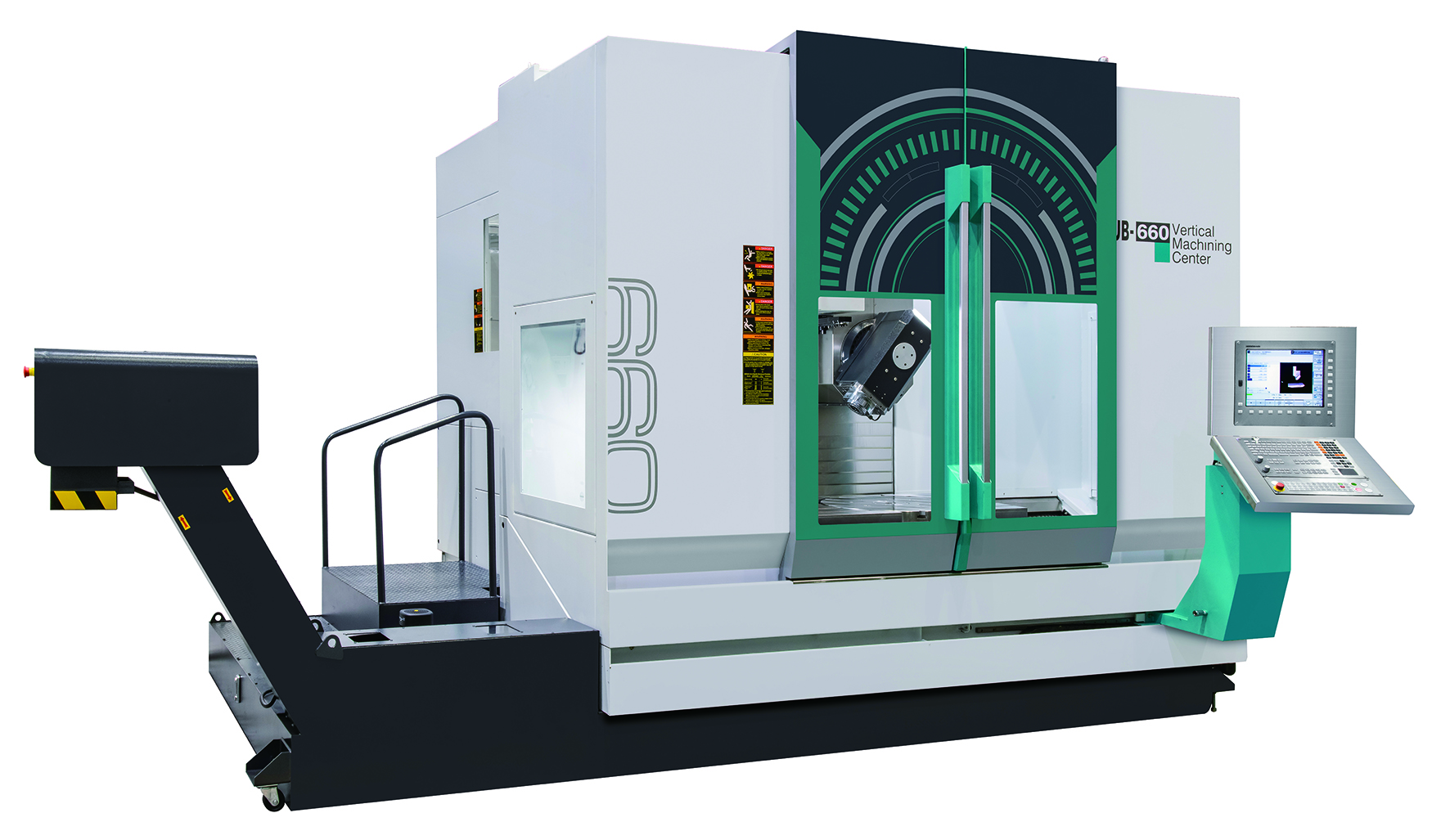

FAIR FRIEND ENTERPRISE CO., LTD.

Product Description :

★Moving column structure :

The M-shaped structure increases anti bend and anti-torsion of the column The counter-weight is supported by the pneumatic cylinder. The shape of the column is similar to the pyramid to increase the stability for moving.

★One piece base structure :

The rigidity of structure is good. The outer shape is not complicated, it is easy for machining. The internal structure adopts the box type design to increase the bearing capacity.The round shape hole is easy to clear sand and increase force flow. The work tableadopts the high and low rail design to increase the rigidity.

★Rotary spindle head structure:

Reduce the interference machining area.

★Modular design :

By changing the column head of the column, etc., the customer can have a variety of opportunities to choose from.

★Turning and milling function(OPT)

Shorten the product manufacturing process. To improve the production efficiency, accuracy and reduce the clamping times and floor space. It can be used in aerospace parts and medical equipment precision molds.

MANFORD MACHINERY CO., LTD.

Product Description :

VX-600 5-Axis Machining Center is designed for multiaxes machining of small and large series of complex 5-side workpieces. With swiveling head and rotary table, VX-series is able to do simultaneous 5 axes machining with high accuracy.

High proformance swiveling head, tilting angle from -120 ~ +30 equipped with 15,000rpm built-in spindle.

VX-600/VX-600T is with an enbedded Ø 630mm diameter rotary table. Any complex workpiece can be accomplished with a single setup.

QUASER MACHINE TOOLS, INC.

Product Description :

Flexible Manufacturing System provides a solution for

massive production or high mix low volume. Simple installation

design helps users to increase productivity in a short time.

The intelligent Automatic Pallet Change Cell has a compact

footprint design with, 6 or 8 pallet options. APC can be field

retrofitted even if the machine is settled months or years ago.

Robotic Tool Magazine Cell is a perfect match for lights out machining.

It also has a small footprint to maximize the user’s facility space.

6 manual loading pockets reduce tooling loading time efficiently.

REN AN INFORMATION TECHNOLOGY CO., LTD.

Product Description :

RenAn's operation simulation workstation is a physical simulation with 3D graphic, showing the cutting and machining process.

[Save consumable cost]: There is no need to worry about the expenditure of consumables, and it will not be affected by pollutants such as waste materials and oil and gas.

[Safety]: Advanced 3D simulation and CNC virtual machine make high risk CNC operation without any danger.

[Smart learning]: Like training the pilot using flight simulators, we use CNC simulator to train the students or operators to be the machinist. Its industrial panel remains the same functionality as real machine that students can practice constantly to accumulate hands-on operation skills.

The controller series of simulator: Fanuc, Siemens, Heidenhain and Mitsubishi.

Turning, Milling, TurnMill, 4 axis, 5 axis.

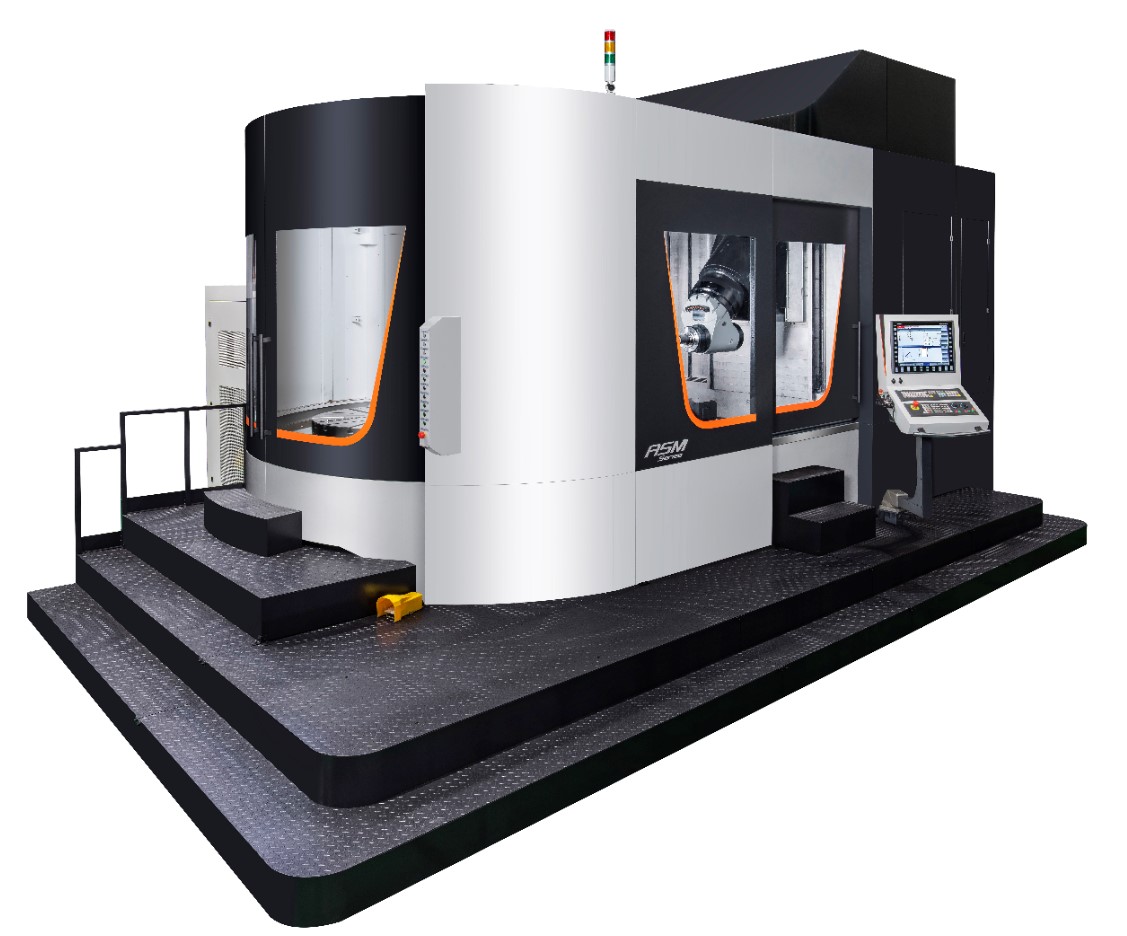

VISION WIDE TECH CO., LTD.

Product Description :

• ASM is the first 5-axis CNC turning and milling machining center of Vision Wide, and it is particularly designed for delicate cylindrical components machining featuring high acceleration, rapid feed-rate and synchronized axes machining, especially for aerospace components, tire molds, turbine blades and aluminum parts.

ASM accessorizes with 5-axis universal head and rotary shafts built-in D.D motor. Through topology analysis, ASM realizes the best distance between tool center point and B-axis transmission

• Positioning P0.006mm

• Repeatability Ps0.0055mm

• Spindle thermal compensation 0.02 mm

• Rapid Traverse 40m/min

• Acceleration 0.3G

• Cutting Feed rate 24 m/min

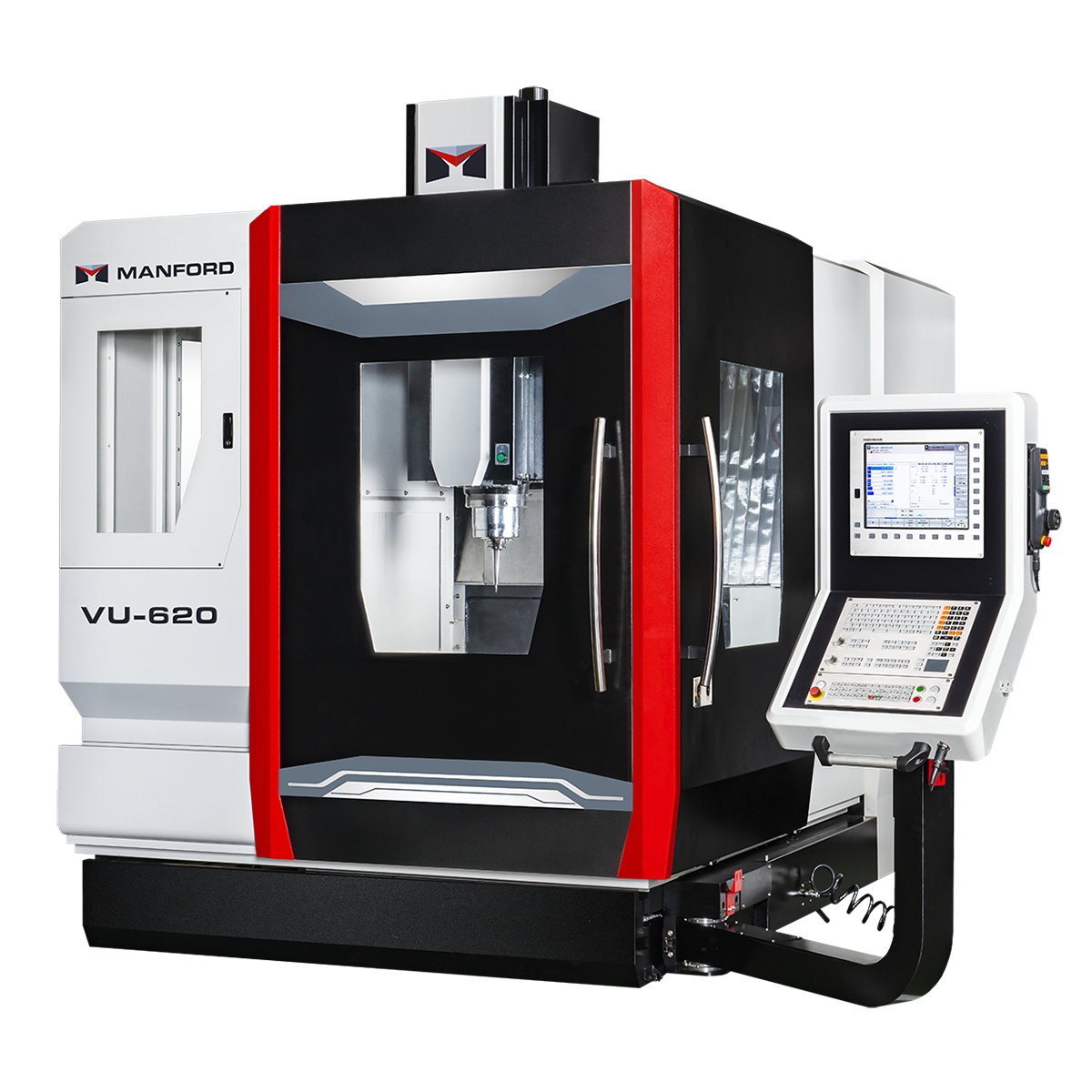

MANFORD MACHINERY CO., LTD.

Product Description :

Turnkey solution of VU-620 product line enables Manford to process and optimize parts efficiently, enhance productivity and accuracy. VU-620 adopts low-pollution components and complies with eco-friendly regulations. Occupying compact floor dimensions is also one of the features of VU-620.

VU-620 offers high speed, high accuracy and more reliable quality. Twin doors design with wide open space is easy for loading workpiece. Movable column C-shape provides superior rigidity. Rotary table with one-piece iron casting provides excellent ductility and greater anti-vibration. Rotary table selection: standard worm gear, or double DD motor.