Theme

Digital Transformation

Green Transformation

ATMAX TECHNOLOGY INTERNATIONAL CO., LTD.

Product Description :

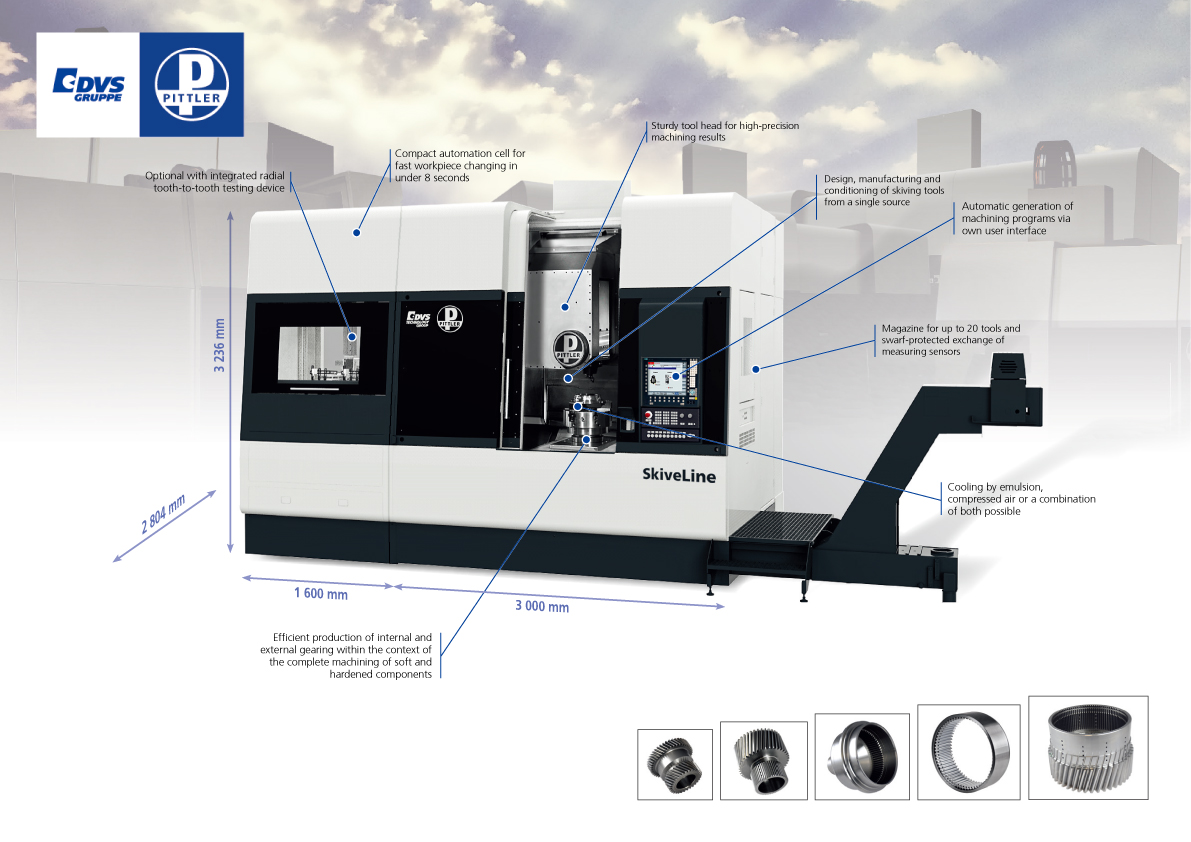

PITTLER SKIVELINE - THE GEAR CUTTING MACHINE THAT CAN DO MORE THAN JUST GEAR CUTTING

Efficient production of internal and external gearings on ring gears, step-pinions, planetary gears or other cylindrical parts with diameter in big range.

Power Skiving or Hard Skiving machine for soft and hardened components.

Sturdy tool head for high-precision machining results.

Complete skiving tool service from one single source – from design of the tool to post-machining.

Automatic generation of gear machining programs via intuitive user interface.

Magazine for up to 20 tools and swarf-protected exchange of measuring sensors.

Compact automation cell for fast workpiece changing in under 8 seconds

Cooling by emulsion, compressed air or a combination of both possible

Optional with integrated radial tooth-to-tooth testing device.

HUNG CHIH LIMITED COMPANY

Product Description :

GROB’s products range from general machining centers to highly flexible automated production systems, from machining assembly units to fully automated assembly lines. Furthermore, motor production and assembly equipments for battery and fuel cell technology are also included in the product range. GROB has thermal spray technology suitable for engine components and can provide customized solutions for the processing of turbine casings, frame structure workpieces, chassis workpieces and battery casings.

Under the framework of Industry 4.0, GROB has taken an important step and launched the GROB-NET4Industry software for future-oriented digital and networked production. GROB has also successfully entered the field of additive manufacturing and developed a new liquid metal printing equipment.

LEADWELL CNC MACHINES MFG., CORP.

Product Description :

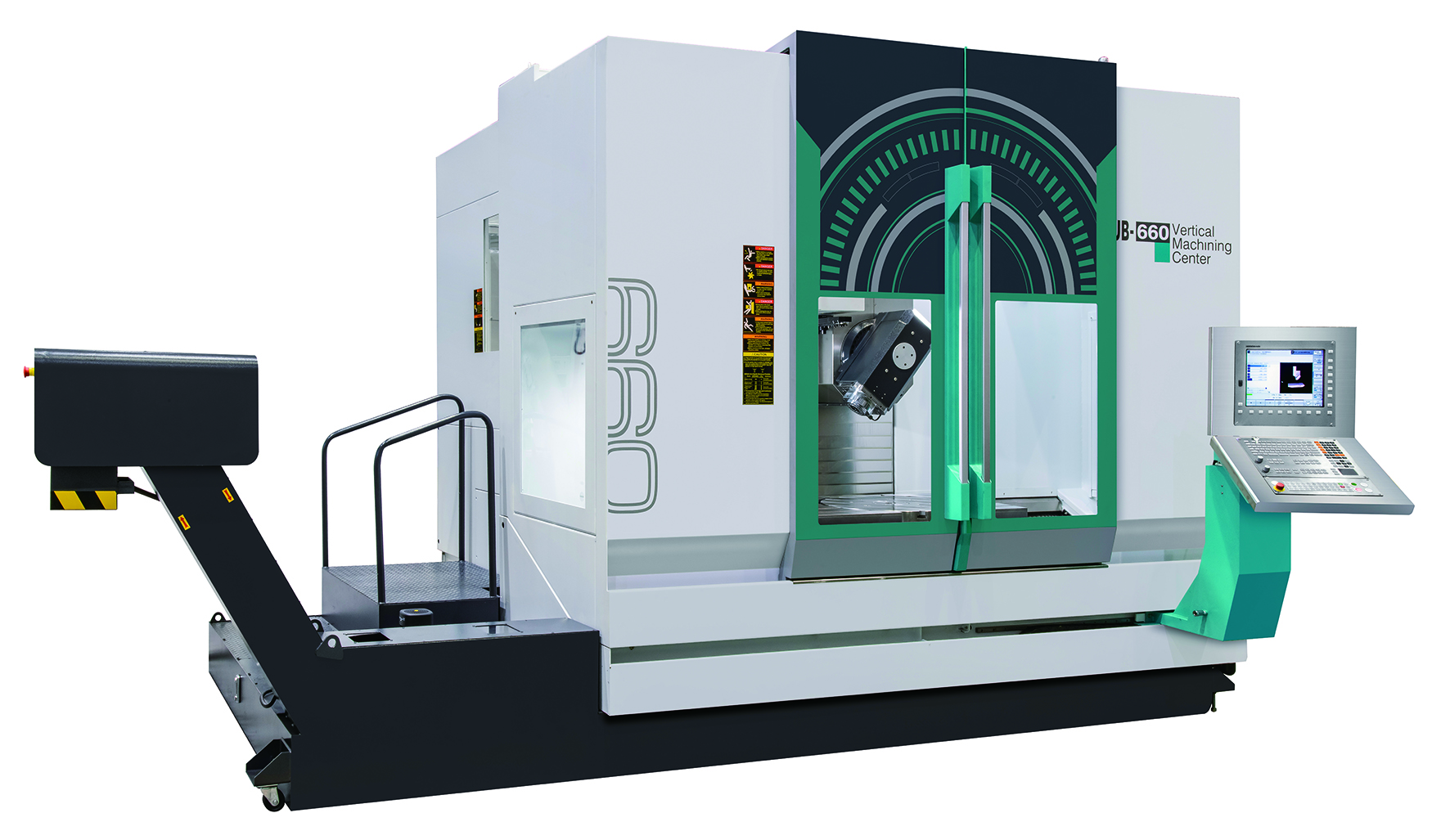

The 5 axes simultaneous processing, can reduce the times of workpiece unloading and the requirement of the jigs, shorten the processing time and improve performance. C-axis table using the DD motor provides high torque and rigidity and can solve the traditional worm gear backlash and worn problems. High torque and efficiency of the spindle with a complete high-rigidity structure applied results in roughing to finishing can be completed on the same machine, suitable for machining hard materials and non-ferrous materials processing.

X-axis travel: 1300mm

Y-axis travel: 610mm

Z-axis travel: 610/750mm

Table size: 1480x610mm

Max. table load: 1600kg

Spindle speed: 12000rpm

C-axis speed: 800rpm

X/Y/Z-axis rapid traverse: 36/36/30 m/min

Tool storage capacity: 30T

QUASER MACHINE TOOLS, INC.

Product Description :

Flexible Manufacturing System provides a solution for

massive production or high mix low volume. Simple installation

design helps users to increase productivity in a short time.

The intelligent Automatic Pallet Change Cell has a compact

footprint design with, 6 or 8 pallet options. APC can be field

retrofitted even if the machine is settled months or years ago.

Robotic Tool Magazine Cell is a perfect match for lights out machining.

It also has a small footprint to maximize the user’s facility space.

6 manual loading pockets reduce tooling loading time efficiently.

FAIR FRIEND ENTERPRISE CO., LTD.

Product Description :

★Moving column structure :

The M-shaped structure increases anti bend and anti-torsion of the column The counter-weight is supported by the pneumatic cylinder. The shape of the column is similar to the pyramid to increase the stability for moving.

★One piece base structure :

The rigidity of structure is good. The outer shape is not complicated, it is easy for machining. The internal structure adopts the box type design to increase the bearing capacity.The round shape hole is easy to clear sand and increase force flow. The work tableadopts the high and low rail design to increase the rigidity.

★Rotary spindle head structure:

Reduce the interference machining area.

★Modular design :

By changing the column head of the column, etc., the customer can have a variety of opportunities to choose from.

★Turning and milling function(OPT)

Shorten the product manufacturing process. To improve the production efficiency, accuracy and reduce the clamping times and floor space. It can be used in aerospace parts and medical equipment precision molds.

MANFORD MACHINERY CO., LTD.

Product Description :

VX-600 5-Axis Machining Center is designed for multiaxes machining of small and large series of complex 5-side workpieces. With swiveling head and rotary table, VX-series is able to do simultaneous 5 axes machining with high accuracy.

High proformance swiveling head, tilting angle from -120 ~ +30 equipped with 15,000rpm built-in spindle.

VX-600/VX-600T is with an enbedded Ø 630mm diameter rotary table. Any complex workpiece can be accomplished with a single setup.

REN AN INFORMATION TECHNOLOGY CO., LTD.

Product Description :

Just like the real CNC machine, equipped with exactly same overall appearance, actual handwheel and real machine operation panel as numerical control machine.

Solving the difficulties of real machine: precise, complicated and very expensive.

With CNC Simulator, everyone can learn CNC machine operation and accumulate hands-on operation skills.

CNC training machine is equipped with exactly same overall appearance, actual handwheel and real machine

operation panel as numerical control machine. Its purpose is to train students for accumulating CNC machine operation skills (program transmission, programming, tool selection, tool compensation and alarm clear )

Overall design is more attractive, and it emphasizes on interaction to make students less mistakes happened.

Not only decreasing learning cost but also letting students work and learn in the safe environment.

MANFORD MACHINERY CO., LTD.

Product Description :

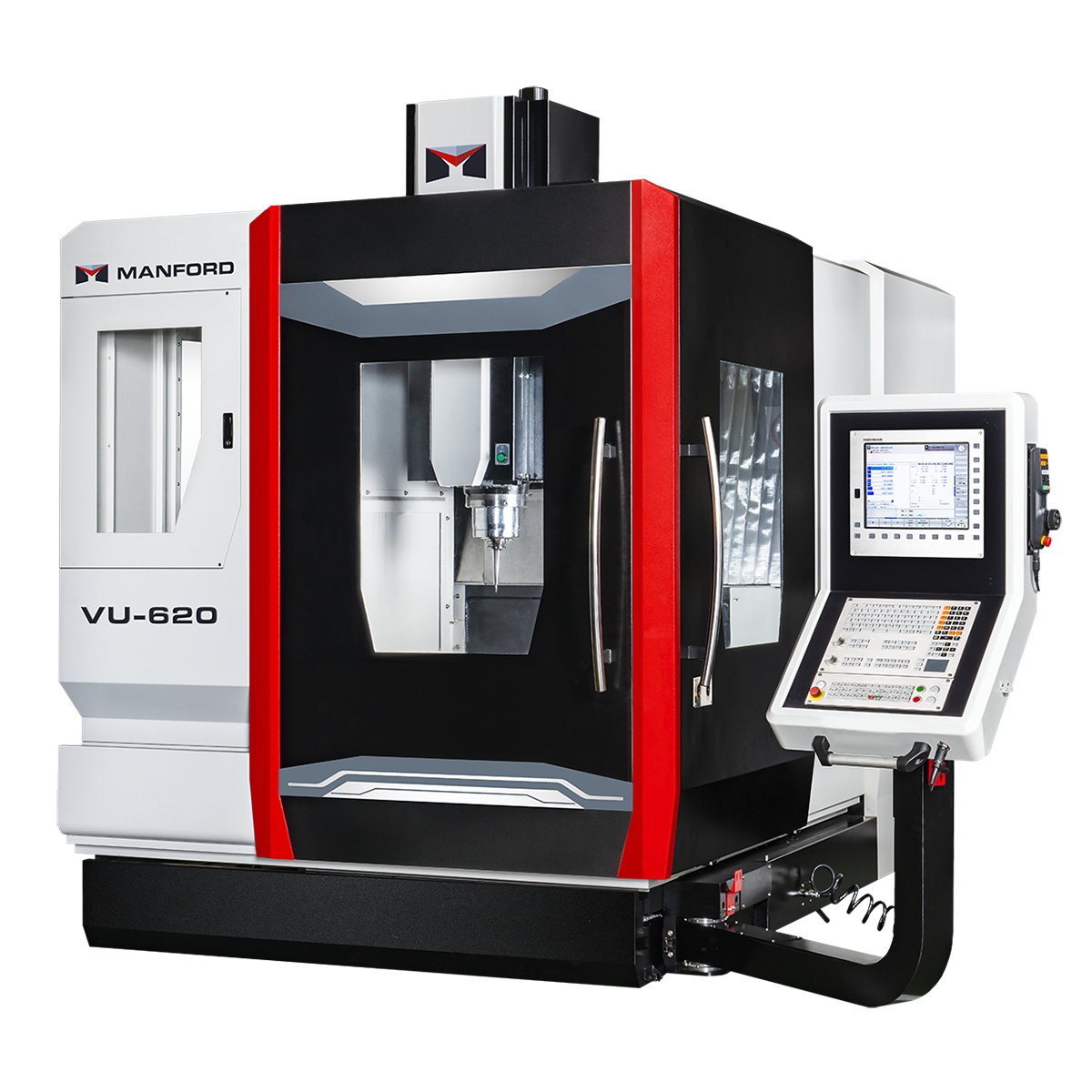

Turnkey solution of VU-620 product line enables Manford to process and optimize parts efficiently, enhance productivity and accuracy. VU-620 adopts low-pollution components and complies with eco-friendly regulations. Occupying compact floor dimensions is also one of the features of VU-620.

VU-620 offers high speed, high accuracy and more reliable quality. Twin doors design with wide open space is easy for loading workpiece. Movable column C-shape provides superior rigidity. Rotary table with one-piece iron casting provides excellent ductility and greater anti-vibration. Rotary table selection: standard worm gear, or double DD motor.

CAMPRO PRECISION MACHINERY CO., LTD.

Product Description :

NV series provide more Y-axis and more working area to meet various demands.

Heavy-duty roller type linear guideways on 3 axes which provide integration of heavy cutting ability from box way and fast movement ability from linear guide way.

Z-axis servo motor with brake replaces counter-balance to provide optimal surface accuracy on 3D machining.

Pretensioned class C3 precision ballscrews on 3 axes help to eliminate blacklash.

Bearings with dust-protection device are assembled by 3 sets both in the front and rear.

One-piece column which designed with shoulder to support tool magazine to decrease vibration and increase the machine stability while tool changes.

Optional max. 4/5-axis table diameter allows more working area and less interference between cutting tools and workpieces.