Theme

Digital Transformation

Green Transformation

HAWE Hydraulik Singapore Pte. Ltd. Taiwan Branch

Product Description :

Compact hydraulic power packs are a type of hydraulic power pack. They arecharacterised by a highly compact design, since the motor shaft of the electric drive also acts as the pump shaft. Compact hydraulic power packs are designed to supply hydraulic circuits with hydraulic fluid.

The compact hydraulic power pack type INKA consists of the tank, the integrated motor and the radial piston pump or gear pump directly attached to the motor

shaft. The directly mounted electronic communication box with integrated realtime operating system allows the operating state to be recorded and visualised. The

measured values of the integrated multi-sensor (including the motor speed) can be passed on to the higher-level machine controls via standardised interfaces and processed there.

The consistently modular design of the type INKA means that different usage volumes and delivery flows can be realised quickly and easily from the modular

system. Compatible, ready-for-connection, complete solutions can be assembled easily using a wide range of connection blocks and the valve banks that can be combined with them.

Features and benefits

■ Prepared for condition monitoring with integrated sensors and communication box

■ Optimum efficiency through under-oil motor cooling, direct power transmission,and sophisticated heat dissipation

■ Suitable for nominal operating modes S2 (short period operation) and S3 (periodic intermittent operation)

■ Resource-saving due to small oil filling volume

Intended applications

■ Machine tools and material testing

■ Hydraulic tools

■ Handling systems

■ Presses and processing machines

QUASER MACHINE TOOLS, INC.

Product Description :

MF700’s design concept is to strengthen Column-moving C frame structure, and separate linear & rotary axes, optimize it with FEMA analyze, the advantages are high rigidity in structure, high precision in machining, and operator friendly. To separate linear & rotary axes is to minimize the following errors and ensure machining accuracy, on top of that, the transmission mechanism/components is away from working area which can reduced parts failure from pollution of coolant and chips.

The linear axes has a cross-frame design, the wide-span column and large-size linear way blocks provides excellent stability during high-speed cutting. Rotary table is intergraded with bridge type column, this compact design can bring us smaller footprint and maximize working envelope.

Rotary table with tailstock support can increase the load capacity which is capable up to 500kg, maximum swing for workpiece is 700mm and height is up to 500mm.

The standard worm gear/wheel and encircling brake design provide high rigidity and lock-force. For different application like high speed demand in aerospace, it can be upgraded with dual Direct Drive Motor.

Operator friendly design with 2 wide open doors are not only easier for operator but also easier for automation upgrade. More thoughtful is we offer three different types of top guards for different work environment, telescope type, solid top cover and open top.

New base design allow chips fall onto conveyor directly, reduce 50% your chip cleaning time.

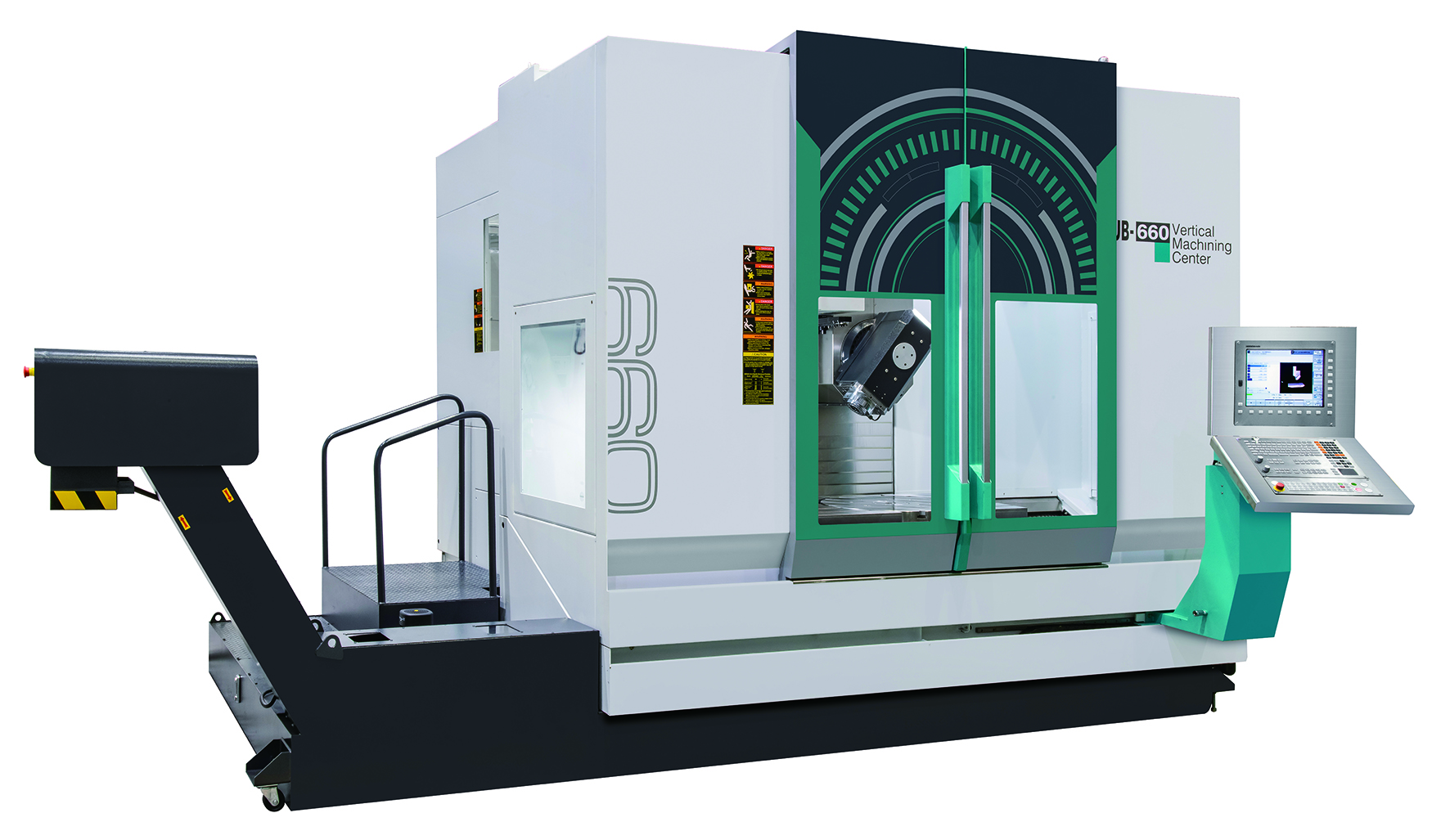

FAIR FRIEND ENTERPRISE CO., LTD.

Product Description :

★Moving column structure :

The M-shaped structure increases anti bend and anti-torsion of the column The counter-weight is supported by the pneumatic cylinder. The shape of the column is similar to the pyramid to increase the stability for moving.

★One piece base structure :

The rigidity of structure is good. The outer shape is not complicated, it is easy for machining. The internal structure adopts the box type design to increase the bearing capacity.The round shape hole is easy to clear sand and increase force flow. The work tableadopts the high and low rail design to increase the rigidity.

★Rotary spindle head structure:

Reduce the interference machining area.

★Modular design :

By changing the column head of the column, etc., the customer can have a variety of opportunities to choose from.

★Turning and milling function(OPT)

Shorten the product manufacturing process. To improve the production efficiency, accuracy and reduce the clamping times and floor space. It can be used in aerospace parts and medical equipment precision molds.

KAO FONG MACHINERY CO., LTD.

Product Description :

5-axis synchronous machining of the KMU series can be used for multi-faceted processing of workpiece clamping positioning at one time or processing deep hole mold and inverted hook area.

Three-axis structure using box-type construction design, which can effectively improve the rigidity of the machine.

X / Y / Z axis with high rigidity roller type linear guideway, with high rigidity, fast moving, low wear and other characteristics, which can greatly enhance the processing dynamic precision and stability and effectively increase production efficiency.

EUMACH CO., LTD.

Product Description :

GVM-800U 專為高精度複雜多曲面銑削而設計,只需一次裝夾,甚至可以車削。從靜態剛性和動態質量的角度來看,每個關鍵部件的堅固框架都經過了很好的優化,以成為最高性能的天車式五軸加工中心。 雙Y軸驅動龍門型結構,絕對抑制了極高速(48m / min)加速/減速產生的振動。不僅可以提高生產前置時間,加工精度,還可以通過緊湊的設計優化工作環境,提高公司的整體管理水平。

直接驅動工作台由二個扭矩電機驅動,A和C軸各一個,最大速度50/100RPM,最大負載920/1200kg,旋轉角度A/C軸±125゚/ 360゚,達到新的高水平動態銑削和車削操作!

刀庫是由交流伺服電機驅動,以簡單,快速,無故障和極其平滑的刀具交換,標準32把刀及更多選擇。高速內藏式銑/車削電主轴18000~24000RPM可供選擇。搭配HEIDENHAIN TNC640,15”螢幕的五軸連動控制器,HEIDENHAIN高精度三軸光學尺,該加工中心用於飛機渦輪元件的加工及鋁製汽車輪圈高速表面處理提高了生產力。

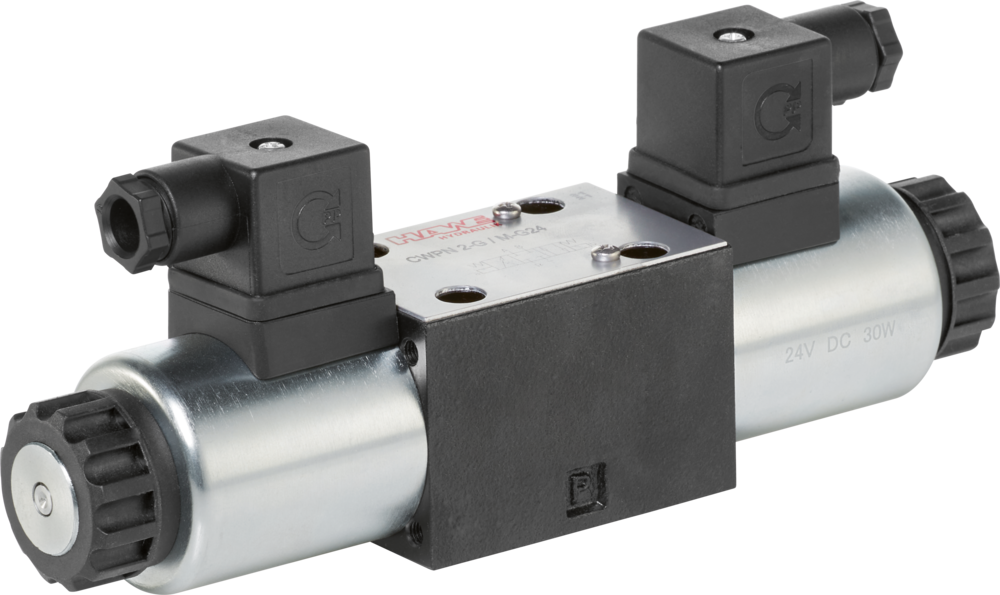

HAWE Hydraulik Singapore Pte. Ltd. Taiwan Branch

Product Description :

Directional spool valves are a type of directional valve. They control the direction of

movement and the velocity of single and double-acting hydraulic consumers.

The directional spool valve type CWPN is a 4/3- or 4/2-way directional valve with standard connection pattern NG 6 (CETOP 03). It is directly actuated and a binary

valve.

The directional spool valve type CWPN can be flexibly combined with the common HAWE valve banks and compact hydraulic power packs. It can also be mounted on customer-specific manifolds or sub-plates.

Features and benefits

■ Universally usable thanks to standard connection pattern NG 6 (CETOP 3) according to ISO 4401-03 or DIN 24 340-A6

■ Modular system with various circuit symbols and actuation variants

■ Optionally also available with additional valves in port P

Intended applications

■ Machine tools

■ Wind turbines

■ Solar power plants

■ Industrial hydraulics

REN AN INFORMATION TECHNOLOGY CO., LTD.

Product Description :

RenAn's operation simulation workstation is a physical simulation with 3D graphic, showing the cutting and machining process.

[Save consumable cost]: There is no need to worry about the expenditure of consumables, and it will not be affected by pollutants such as waste materials and oil and gas.

[Safety]: Advanced 3D simulation and CNC virtual machine make high risk CNC operation without any danger.

[Smart learning]: Like training the pilot using flight simulators, we use CNC simulator to train the students or operators to be the machinist. Its industrial panel remains the same functionality as real machine that students can practice constantly to accumulate hands-on operation skills.

The controller series of simulator: Fanuc, Siemens, Heidenhain and Mitsubishi.

Turning, Milling, TurnMill, 4 axis, 5 axis.

FAIR FRIEND ENTERPRISE CO., LTD.

Product Description :

★Optimized structure configuration

- The base and column are structured as one-Piece casting, which eliminates possible tolerance of the jointing interface.

- Box-opstructure casting and optimal span realize exceptional rigidity and stability.

★Overlapped Axes with 2 Rotating Axes

- Axes of linear movement and rotation are separated so that during 5-axis machining, curve tolerance or error can be controlled and adjusted rather easily.

★3 Axes Motion Area Partitioned Processing Area

- Effective In addition to space chips removal, promoting Antifouling capability, optimal span realize exceptional rigidity and stability.

★Chip removal function

- Forming one large funnel chips off, high performance chip removal

LEADWELL CNC MACHINES MFG., CORP.

Product Description :

The 5 axes simultaneous processing, can reduce the times of workpiece unloading and the requirement of the jigs, shorten the processing time and improve performance. C-axis table using the DD motor provides high torque and rigidity and can solve the traditional worm gear backlash and worn problems. High torque and efficiency of the spindle with a complete high-rigidity structure applied results in roughing to finishing can be completed on the same machine, suitable for machining hard materials and non-ferrous materials processing.

X-axis travel: 1300mm

Y-axis travel: 610mm

Z-axis travel: 610/750mm

Table size: 1480x610mm

Max. table load: 1600kg

Spindle speed: 12000rpm

C-axis speed: 800rpm

X/Y/Z-axis rapid traverse: 36/36/30 m/min

Tool storage capacity: 30T

CAMPRO PRECISION MACHINERY CO., LTD.

Product Description :

NV series provide more Y-axis and more working area to meet various demands.

Heavy-duty roller type linear guideways on 3 axes which provide integration of heavy cutting ability from box way and fast movement ability from linear guide way.

Z-axis servo motor with brake replaces counter-balance to provide optimal surface accuracy on 3D machining.

Pretensioned class C3 precision ballscrews on 3 axes help to eliminate blacklash.

Bearings with dust-protection device are assembled by 3 sets both in the front and rear.

One-piece column which designed with shoulder to support tool magazine to decrease vibration and increase the machine stability while tool changes.

Optional max. 4/5-axis table diameter allows more working area and less interference between cutting tools and workpieces.

REN AN INFORMATION TECHNOLOGY CO., LTD.

Product Description :

Just like the real CNC machine, equipped with exactly same overall appearance, actual handwheel and real machine operation panel as numerical control machine.

Solving the difficulties of real machine: precise, complicated and very expensive.

With CNC Simulator, everyone can learn CNC machine operation and accumulate hands-on operation skills.

CNC training machine is equipped with exactly same overall appearance, actual handwheel and real machine

operation panel as numerical control machine. Its purpose is to train students for accumulating CNC machine operation skills (program transmission, programming, tool selection, tool compensation and alarm clear )

Overall design is more attractive, and it emphasizes on interaction to make students less mistakes happened.

Not only decreasing learning cost but also letting students work and learn in the safe environment.