Theme

Digital Transformation

Green Transformation

LITZ HITECH CORP.

Product Description :

1. 堅強的龍門型結構設計,與U型底座<br />設計。<br />2. 高剛性的天車式設計。<br />3. Y軸雙伺服馬達與雙螺桿驅動。<br />4. A軸採內藏式,雙支撐雙驅動系統。<br />5. 高扭矩高精度的AC軸旋轉台。<br />6. 具備銑/車功能

ATMAX TECHNOLOGY INTERNATIONAL CO., LTD.

Product Description :

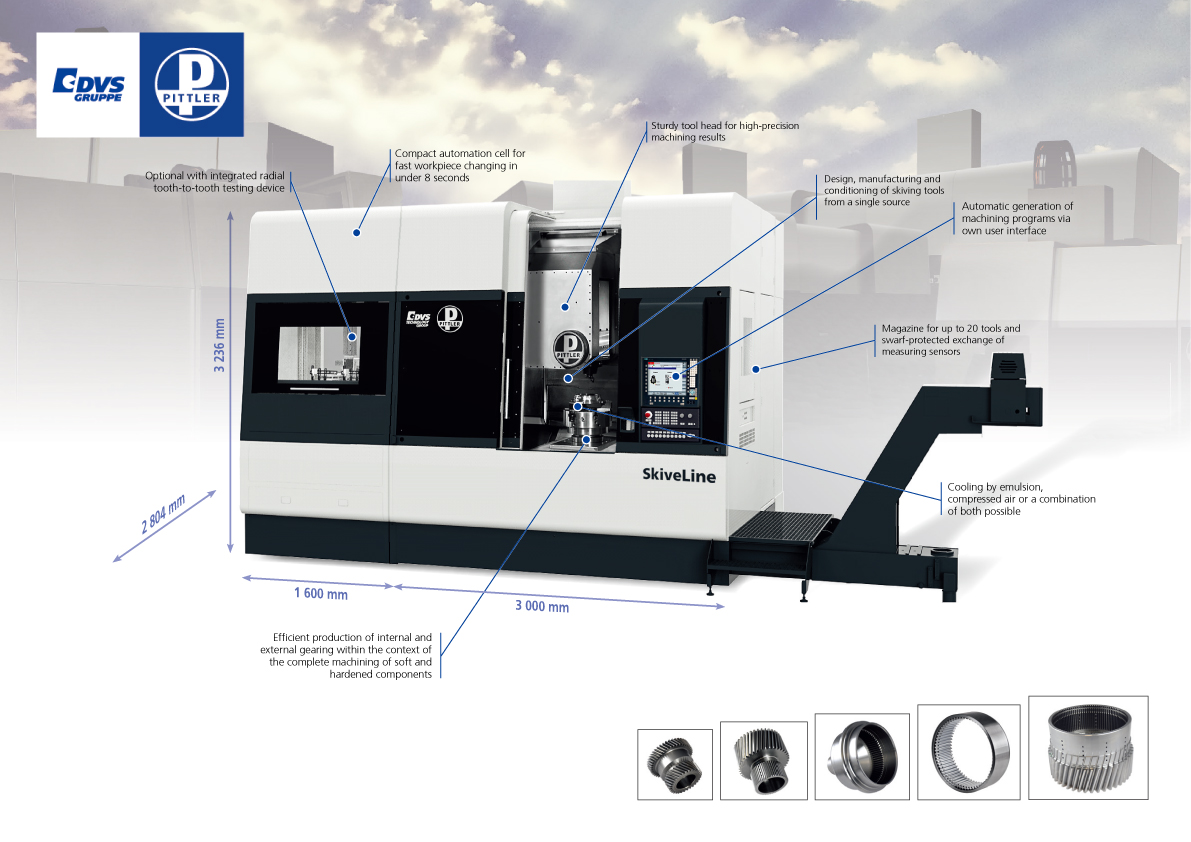

PITTLER SKIVELINE - THE GEAR CUTTING MACHINE THAT CAN DO MORE THAN JUST GEAR CUTTING

Efficient production of internal and external gearings on ring gears, step-pinions, planetary gears or other cylindrical parts with diameter in big range.

Power Skiving or Hard Skiving machine for soft and hardened components.

Sturdy tool head for high-precision machining results.

Complete skiving tool service from one single source – from design of the tool to post-machining.

Automatic generation of gear machining programs via intuitive user interface.

Magazine for up to 20 tools and swarf-protected exchange of measuring sensors.

Compact automation cell for fast workpiece changing in under 8 seconds

Cooling by emulsion, compressed air or a combination of both possible

Optional with integrated radial tooth-to-tooth testing device.

QUASER MACHINE TOOLS, INC.

Product Description :

Flexible Manufacturing System provides a solution for

massive production or high mix low volume. Simple installation

design helps users to increase productivity in a short time.

The intelligent Automatic Pallet Change Cell has a compact

footprint design with, 6 or 8 pallet options. APC can be field

retrofitted even if the machine is settled months or years ago.

Robotic Tool Magazine Cell is a perfect match for lights out machining.

It also has a small footprint to maximize the user’s facility space.

6 manual loading pockets reduce tooling loading time efficiently.

GENTIGER MACHINERY INDUSTRIAL CO., LTD.

Product Description :

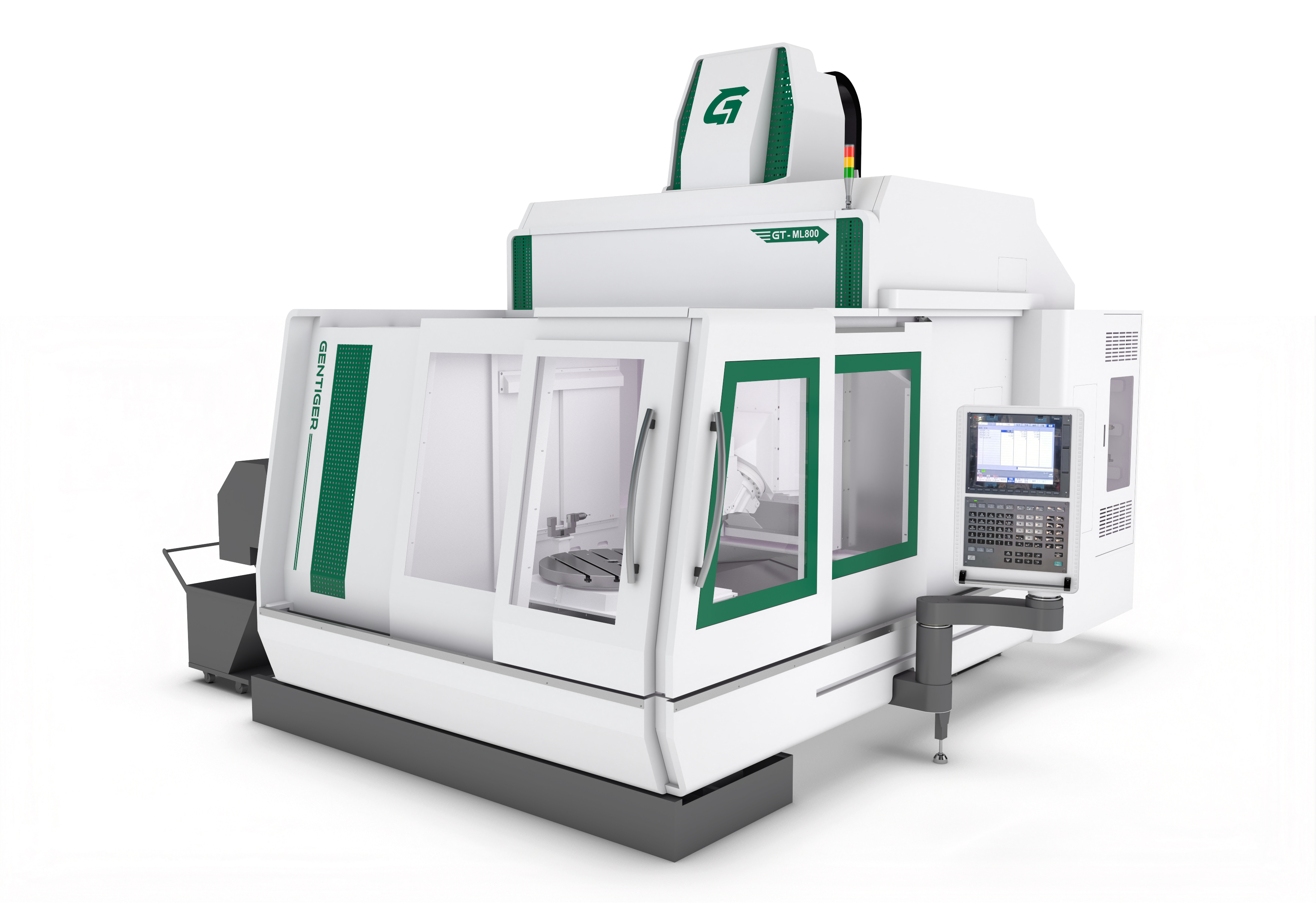

• Closed-type double-column structure, it increases structure dramatically increases the structural rigidity of the machine and maintains extraordinary stability at all times.

• Roller-type linear guideway on three axes, it achieves high loading resistance, high rigidity, long service life, low thermal growth, and low noise.

• Three linear guideways on the Y axis, it provides more stable support for the spindle head, which contributes to upgraded stability in machining.

• The 45° vertical horizontal swiveling head is applicable for both vertical and horizontal machining, increasing flexibility in machining applications.

WELE MECHATRONIC CO., LTD.

Product Description :

1.立車主軸轉盤以進口交叉滾子軸承設計,確保重負荷的能力及長期的精度壽命。

2. Z軸226 mm方型滑枕搪孔軸採硬軌配Turcite B結構,VTC1612-CW標準行程900mm。

3.底座、立柱、橫樑、工作台等大型鑄件依製造需要,經由最新的3D設計,剛性最佳化,並以

多年經驗訂定有效的退火程序以消除殘餘應力,多年實際應用經驗,確實能達成有效的長期精

度保持性。

4.X、Z軸標準配備採用「雙編碼器」的「雙」半閉環回饋系統,經濟有效的提高各軸的定位精度。

(X、Z軸可選購德國Heidenhain或西班牙FAGOR光學尺)。

5.VTC-CW標準刀庫容量為16P(16儲位),車刀型式及分配數目可依客戶要求處理。

6.主軸箱等關鍵零件係利用自有的「大型臥式鏜孔機」及「大型高精度三次元量測儀(三座標量床)」

確實達成應有的加工精度,確保優良的組裝基礎。

7.承襲歐美先進工具機廠的標準,以嚴格維護的「1.2米x1.2米」高精密度的方形標準平板做為精密

精度的基礎,對各項關鍵零件進行精密鏟花(刮研),使機器的各處結合面和滑動面均能達到正確的

幾何精度,確保機器應有的精度和壽命。

8.搭配高規格的Fanuc數控系統,標準功能包含:15吋彩色液晶螢幕、Fanuc全鍵式操作面板、

2MB記憶容量、Ethernet網路接口、Flash記憶卡插口、剛性攻牙及各種特殊補間(插補)等多項

高規格功能,能經濟有效的滿足各種使用需求。

9.採用的各項配套零組件均經過長期使用驗證,可確保機器長期運行的可靠性。

10.完整的品檢測試流程,搭配先進的自動光學直準儀、雷射干涉儀、球桿檢測儀、線上動平衡儀等

精密檢測儀器,確保出廠的機器都能達到設計的性能和應有的功能。

11.經驗豐富的研發團隊,突破老舊的包袱,協助客戶達成各種特殊需求。

12.兼具經驗和熱誠的服務團隊和完整的服務體系,可以及時有效的讓用戶的機器長保最佳使用狀態。