Theme

Digital Transformation

Green Transformation

SIGMA CNC TECHNOLOGY MACHINERY CO., LTD.

Product Description :

The brand-new product CNC Vertical Complex Grinding Machine SVG-E800 (SVG series), suitable for composite grinding of inner and outer diameters and end faces of various big cylindrical workpieces. Its mechanical structure adopts a double column type design, featuring high rigidity, high precision, high stability, and high efficiency. It is encased in aesthetically pleasing fully enclosed safety covers, and can be equipped with controllers from Fanuc, Mitsubishi, or the latest generation. With its conversational interface, operation is intuitive and easy. The grinding wheel spindle system is HSK-A100, 10000rpm, 18.5/15kw, capable of automatically changing wheel holders, with an ATC device capacity of 6 tools, and a spindle angle positioning system at 0 degrees/22.5 degrees, enabling various grinding processes with just one clamping. The workpiece spindle adopts a hydrostatic system turntable with a diameter of 800mm, maintaining axial movement accuracy <1μm. Models with turntable diameters of 600mm and 1200mm are also available. For further technical specifications, please contact the Sales Department of SIGMA CNC.

FALCON MACHINE TOOLS CO., LTD.

Product Description :

Chevalier’s FSG-ADIV Series of surface grinders have several design features to shorten your processing and non-processing preparation while delivering high-precision workpieces year after year—functions you might not expect on such affordable machines: iSurface control, variable speed spindle, constant surface speed, loading detection and in-machine manual dynamic balancing.

FSG-ADIV Series grinders also feature tools to secure Big Data with Chevalier’s exclusive iMachine Communications System TM (iMCS).

This software package, combined with data analysis, enhances machine efficiency in the factory while enabling remote monitoring and diagnostics to track machine performance and identify potential problems before they begin.

HYPERMAX MACHINERY CO., LTD.

Product Description :

1μ control-setting system and a design of high-rigidity roller rail track enhance the precision of locating axis. Also, JG1 integrates multiple processes, one chucking then inner face, bore and end face, into full grinding processes. Its powerful working capability completes a serial of 8 procedures at one time.

TAIWAN MORE-CASH VILLAGE CORP.

Product Description :

For 34.1mm-52mm Twist Drill Re-sharpening , Angle 118°-140°

Precise Grinding Results , Precision Assurance within 0.1mm

Easy to Operate , grinding a drill within 10 seconds.

Special Design High Accuracy Alloy Steel Collets

Accurate Grinding consumption 0.2mm

High Efficiency DC motor

Stable Quality Grinding Wheel

Considerable Design, Invisible Tool Box, Delicate & Friendly Use

KCW ETERNAL ENTERPRISE CO., LTD.

Product Description :

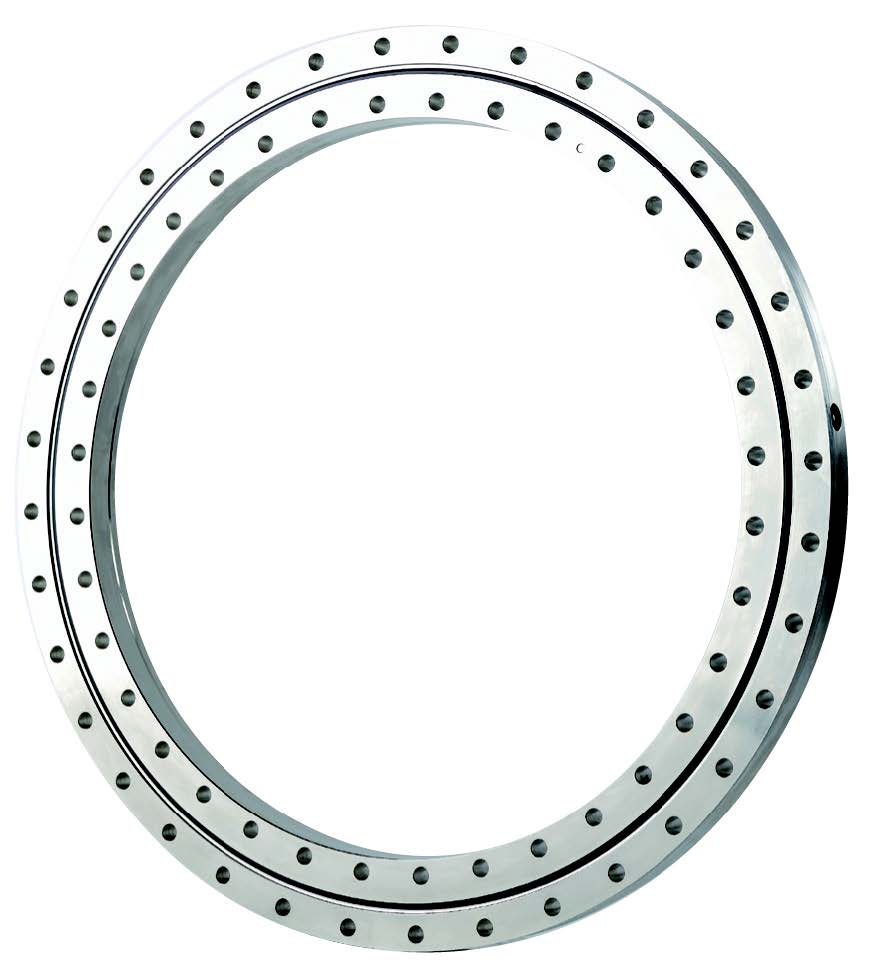

The Rollix precision slewing ring series is specially designed to meet the precision needs of customers.

High precision, high rigidity, low torque and smooth rotation

The simple design combines the functions of high load-bearing, rotation and locking holes.

Mass-produced pre-load structure with highly stable precision and quality

Convenient and fast design and installation, reducing matching components

We have planned inventories at Taiwan and abroad factory to speed up the development of prototypes.

PALMARY MACHINERY CO., LTD.

Product Description :

For various eccentric circle or non-round shape workpieces grinding purpose, PALMARY develop CNC Cylindrical Grinder Cam Type with CAD/CAM software for easily transfer from workpiece drawing to grinding program. The workhead could offer precise angle control upto 0.1 micron resolution due to the C axis has accurate angle encoder. The infeed axis is driven by linear motor with linear guideway & close loop linear scale, it could avoid the backlash in order to reach high machining precision. Also, it could prevent the reaction force causing by linear motor under the large acceleration and deceleration motion, it could stabilize the grinding process.

GRINTIMATE PRECISION INDUSTRY CO., LTD.

Product Description :

a.Equipped with exclusive high rigidity hydrostatic rotary table, static rigidity greater than 400kgf/μm, Φ600/800table with a load capacity of >10000KG.

b.Mitsubishi/Fanuc controller available, with human-machine interface(HMI) which features fast communication and convenient for user-friendly operation.

c.The high rigidity of our hydrostatic spindle both radially and axially enables our spindles to produce a wide range of finishes-from speedy heavy cutting of >0.3mm to mirror-like finish.

d.To maximize stability and load capacity, the Y-axis(up/down) and the Z-axis (forward/backward) of the grinding wheel spindle are equipped with SCHNEEBERGER/THK/NSK lineal guideway.

e.Equipped with THK/NSK high precision ballscrews, ensuring the zero backlash feeding.

f.Our products are on hundred percent designed and manufactured in Taiwan. To guarantee the stability of machine, all of the cast components go through a pressure relieve process