Theme

Digital Transformation

Green Transformation

TES ELECTRICAL ELECTRONIC CORP.

Product Description :

■ Measures acceleration, Velocity and displacement

■ Maximum/Minimum record function

■ Earphone output for detecting noise in machine components

■ Manual memory stores up to 99 data

■ RMS, EQ PEAK and EQ P-P measurement

■ Wide range of vibration measurement by using different sensitivity of accelerometers

■ Excellent accelerometer for harsh environments

APACER TECHNOLOGY INC.

Product Description :

一機可檢測十種藥瓶樣式,使用新式旋轉夾具,全自動檢測無須更換治具;搭配多角度鏡頭360度拍攝,精準取像並加速檢測。雙中控台顯示與分料口設計,In-line方式配合產線進出料動線;結合自主研發AOI檢測軟體快速辨別並標示藥瓶的不良區,協助品管人員驗證更增進作業效率。

瞭解更多:https://iiot.apacer.com/tw/optical-inspection/ai-aoi-automation/

更多實績案例,歡迎參考Apacer宇瞻智慧物聯官網:https://iiot.apacer.com/tw/case-studies/

EQP SERIES CO., LTD

Product Description :

This system is versatile and can be used not only for general vibration monitoring but also for measurements in challenging environments and is compatible with intrinsic safety and explosion-proof requirements. The Vibrating Converter MODEL-2503 is a system that can accommodate various sensors and specifications.

A vibration monitoring system using the Intrinsic Safety Explosion-proof Detector MODEL-2450EX is composed of detectors, barriers (safety retainers), and MODEL-2503 installed in hazardous locations.

The output includes not only DC4-20mA but also two systems of vibrating waveform AC±2V. This allows not only observation on digital monitors but also connectivity to various PLCs, contributing to the IoT compatibility of facilities.

Can be used in conjunction with the high-sensitivity piezoelectric accelerometer MODEL2430.

FARSIGHT PRECISION CO., LTD.

Product Description :

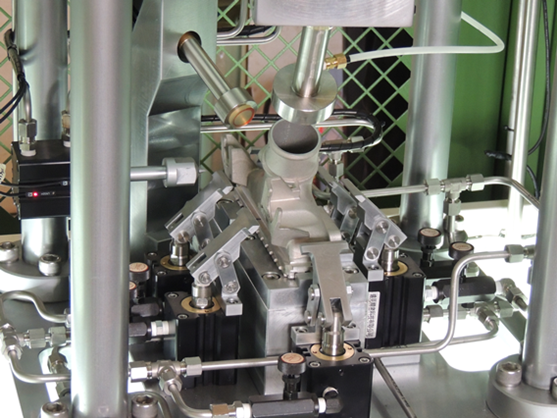

Finished leaking testing just only 1 minute !!!

Leaking Testing Machine (Pressure testing machine)

◎ Our company could according to products request of

condition of client, design and manufacturing dry type,

wet type or dry-wet 2 ways in one leaking testing

machine.

◎ 2 workpiece finished at the same time.

◎ The client can select the "COSMO", "FUKUDA" or other

leaking testing instrument, and install user-interface

system.

◎ Attach computer storage, calculation and network output

etc...

◎ The equipment could exchange the workpiece quickly.

◎ The equipment could exchange fixtures for other

workpiece.

◎ It can set the water tank in time.

◎ The client can option to mark on workpiece with laser or

punching.

G-TECH INSTRUMENTS INC.

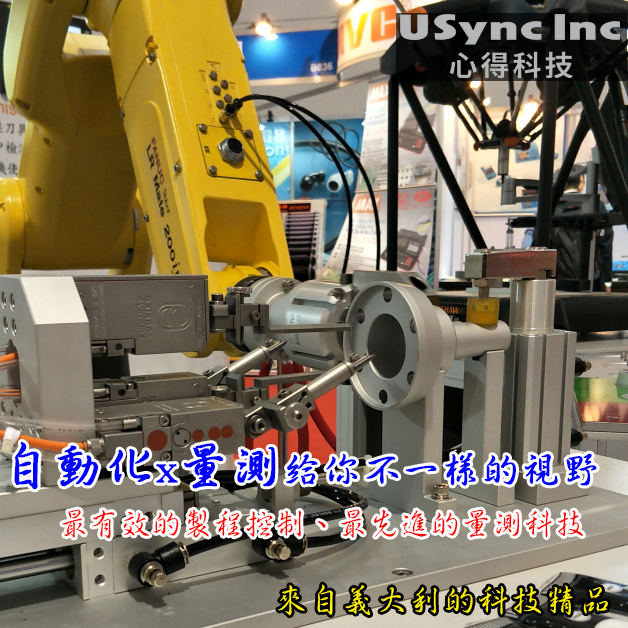

Product Description :

The performance of the spindle is an important key to processing quality. When you understand the performance of the spindle, you can predict and control the quality of the processed parts. The shape accuracy, roundness, and surface roughness of the workpieces are all related to the performance of the spindle. Only when the spindle is real measuring the accuracy of the spindle at the processing speed of the machine has meaning to the control of the quality of the processed parts, so measuring and understanding the performance of the machine tool, finding the best working speed, determining the warm-up time, even confirm the accuracy of the spindle after the collision.

LION provided this SEA analysis system as early as 1993 to help spindle manufacturers, machine tool factories and processing plants to reduce workpiece defect rate and improve product quality.

★The SEA system complies with the following international standards:

✓ ANSI / ASME B5.54-2005: "Methods for Performance Evaluation of CNC Machining Centers"

✓ ISO230: Test Code for Machine Tools, 3: "Determination of Thermal Effects" 7: "Geometric Accuracy of Axes of Rotation"

✓ ANSI / ASME B5.57-1998: "Methods for Performance Evaluation of CNC Turning Centers"

✓ ANSI / ASME B89.3.4: "Axes of Rotation, Methods for Specifying and Testing"

RAISE PRECISION CO., LTD.

Product Description :

CAPTRON is an experienced measuring technology manufacturer for the industry and the market leader in fill level measurement in the field of dispensing technology. Capacitive CAPTRON probes accurately and reliable measure the fill levels of liquids, bulky goods, pastes, adhesives and chemically aggressive materials.

With the CAPselect system for level sensors, you are able to freely configure the probe of your choice depending on the application, container type and sensor properties. CAPTRON produces these with millimetre accuracy to ensure full flexibility.

There are two systems to choose from: Compact probes, in which the electronics and probe form a single unit. Probes with external amplifiers that are suitable for applications with high temperatures and pressures.

Thanks to their wear-free electronics combined with high-quality material such as stainless steel, Teflon and Peek, CAPTRON level sensors are reliable, robust and long-lasting.

KTR TAIWAN LTD.

Product Description :

❙MONITEX BT torque sensor❙

The new MONITEX® BT is a precise tool for daily measuring tasks in test bench technology. With the help of the apps(Android/iOS) or the PC software, torque and speed data can be displayed and saved in a matter of seconds.

1. COST-SAVING- thanks to new integrated design, cost down no longer a dream but a fact.

2. Inaccuracy 0.2%! with wireless BlueTooth coonection, one device get eveyring!

3. SPACER-SAVING- the new measurement coupling can be integrated into the drive in a few simple steps in contrast to classical torque measurement.

4. Error alert- imediate feedback on abnormal data throgh APP

Don't hesitate to call 04-23593278 or send to ktr-tw@ktr.com, both ways are welcome.

G-TECH INSTRUMENTS INC.

Product Description :

To reduce damages caused by accidental collision, and to record collision events.

✓ Smart monitoring box consisting of sensors & electronics

✓ High bandwidth MEMS tri-axial accelerometer (X, Y & Z)

✓ Relay triggered in less than 1 millisecond upon a collision

✓ Built-in data log for max. 5,000 collision events

✓ Easy installation on machine structure

✓ Easy software for threshold setting & logging

✓ Economically priced