Theme

Digital Transformation

Green Transformation

EQP SERIES CO., LTD

Product Description :

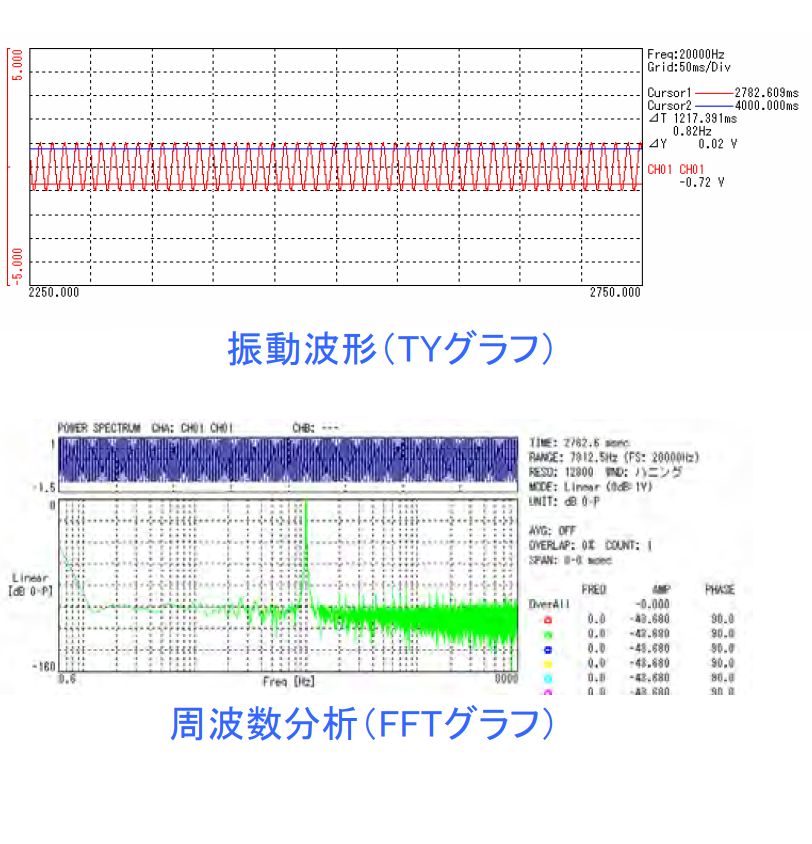

Connect various vibration meters for vibration analysis.

It is a waveform acquisition and analysis software capable of handling up to 32 channels.

It provides waveform (TY) graphs, FFT graphs, XY graphs.

Real-time or post-processing waveform analysis is possible.

You can add any filters or perform recalculations in post-processing.

It also allows for audio playback of waveform data.

Compatible with various types of vibration meters.

FARSIGHT PRECISION CO., LTD.

Product Description :

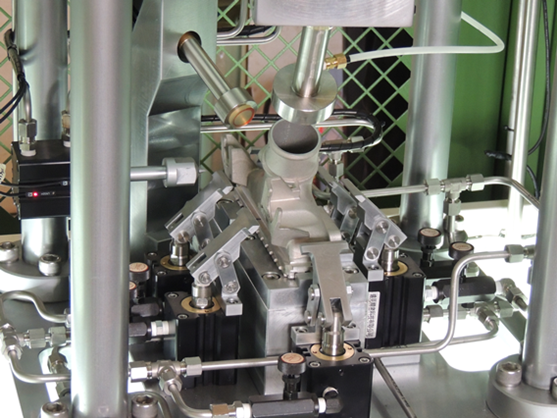

Finished leaking testing just only 1 minute !!!

Leaking Testing Machine (Pressure testing machine)

◎ Our company could according to products request of

condition of client, design and manufacturing dry type,

wet type or dry-wet 2 ways in one leaking testing

machine.

◎ 2 workpiece finished at the same time.

◎ The client can select the "COSMO", "FUKUDA" or other

leaking testing instrument, and install user-interface

system.

◎ Attach computer storage, calculation and network output

etc...

◎ The equipment could exchange the workpiece quickly.

◎ The equipment could exchange fixtures for other

workpiece.

◎ It can set the water tank in time.

◎ The client can option to mark on workpiece with laser or

punching.

G-TECH INSTRUMENTS INC.

Product Description :

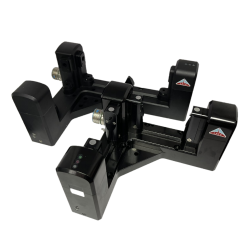

To reduce damages caused by accidental collision, and to record collision events.

✓ Smart monitoring box consisting of sensors & electronics

✓ High bandwidth MEMS tri-axial accelerometer (X, Y & Z)

✓ Relay triggered in less than 1 millisecond upon a collision

✓ Built-in data log for max. 5,000 collision events

✓ Easy installation on machine structure

✓ Easy software for threshold setting & logging

✓ Economically priced

G-TECH INSTRUMENTS INC.

Product Description :

★Multi-Channel Dynamic Measurement: 4-CH simultaneous analog input, compatible to accelerometer, microphone, etc.

★Digital Data Processing: Local real-time computing, data storage, and transmit to data center via ethernet.

★Test & Measurement : Remote Mode--FFT Analyzer;Standalone Mode--Data Recorder & Transmitter.

★Condition Monitoring: Programable multiple I/O interface, connect to controller for intelligent manufacture.

G-TECH INSTRUMENTS INC.

Product Description :

The performance of the spindle is an important key to processing quality. When you understand the performance of the spindle, you can predict and control the quality of the processed parts. The shape accuracy, roundness, and surface roughness of the workpieces are all related to the performance of the spindle. Only when the spindle is real measuring the accuracy of the spindle at the processing speed of the machine has meaning to the control of the quality of the processed parts, so measuring and understanding the performance of the machine tool, finding the best working speed, determining the warm-up time, even confirm the accuracy of the spindle after the collision.

LION provided this SEA analysis system as early as 1993 to help spindle manufacturers, machine tool factories and processing plants to reduce workpiece defect rate and improve product quality.

★The SEA system complies with the following international standards:

✓ ANSI / ASME B5.54-2005: "Methods for Performance Evaluation of CNC Machining Centers"

✓ ISO230: Test Code for Machine Tools, 3: "Determination of Thermal Effects" 7: "Geometric Accuracy of Axes of Rotation"

✓ ANSI / ASME B5.57-1998: "Methods for Performance Evaluation of CNC Turning Centers"

✓ ANSI / ASME B89.3.4: "Axes of Rotation, Methods for Specifying and Testing"

RAISE PRECISION CO., LTD.

Product Description :

Capacitive switches with touch sensor technology

The first capacitive switches with touch sensor technology from CAPTRON were used in 1994 for public transportation. Today, CAPTRON offers a wide range of capacitive SENSORswitches for various industries and applications where unconditional reliability, durability, comfort and design are required.

If necessary, SENSORswitches from the standard range can be tailored and modified optically and technically to meet individual customer demands.