Theme

Digital Transformation

Green Transformation

BLUM PRODUCTION METROLOGY CO., LTD.

Product Description :

• Measuring speed up to 3 m/min

• Precise, non-lobing touch characteristics

• No-wear, optoelectronic measuring mechanism

• Use of two measuring systems with one IR receiver

• Extended battery life

• Precise measurement even with coolant

• Proven and robust design

APACER TECHNOLOGY INC.

Product Description :

一機可檢測十種藥瓶樣式,使用新式旋轉夾具,全自動檢測無須更換治具;搭配多角度鏡頭360度拍攝,精準取像並加速檢測。雙中控台顯示與分料口設計,In-line方式配合產線進出料動線;結合自主研發AOI檢測軟體快速辨別並標示藥瓶的不良區,協助品管人員驗證更增進作業效率。

瞭解更多:https://iiot.apacer.com/tw/optical-inspection/ai-aoi-automation/

更多實績案例,歡迎參考Apacer宇瞻智慧物聯官網:https://iiot.apacer.com/tw/case-studies/

DA CEI TRADE CO.,LTD.

Product Description :

* Electric heater for generating the high temp. hot-air of the hige pressure.

* Temp. control can be be satisfactory because A-sensor (for detecting the hot-air of the outlet) and B-sensor (for

detecting the hot-star and overheat temp. ) is incorporated.

* Life of the heater element becomes long and the high temp. hot-air of 800゚C can be used the long time stably by using

with Multi-controller TRC202.

* Hot-start operation for intermittent operation is possible by using with Multi-controller TRC202.

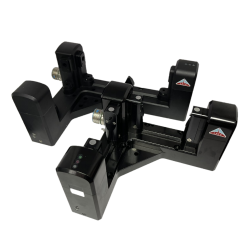

BLUM PRODUCTION METROLOGY CO., LTD.

Product Description :

• Tool breakage detection

• Tool length measurement

• Machine axes compensation

• Temperature compensation

RAISE PRECISION CO., LTD.

Product Description :

The compact, high-resolution MiniCODERs have proven their value for speed and position acquisition in highly dynamic applications. They use their full potential when installation situations with little space require a particularly compact, robust and reliable measuring system. The magnetic measuring systems consist of a ferromagnetic target wheel and a scanning unit. Without dedicated bearings, they are completely wear-free and maintenance-free. The optimised circuit and screening technique, and fully encapsulated electronics ensure reliable operation even in harsh environments.

KTR TAIWAN LTD.

Product Description :

ROTEX® torsional flexible couplings are characterized by small dimensions, low weight and low mass moments of inertia yet transmit high torques. Running quality and service life of the coupling are improved by accurate all-over machining. Their application is ideal for transmitting torque while damping torsional vibrations and absorbing shocks produced by the uneven operation of certain prime movers.

ROTEX® torsional flexible couplings are equipped with the new temperature resistant T-PUR® spider which is available in three different degrees of Shore hardness.

RAISE PRECISION CO., LTD.

Product Description :

CAPTRON, pioneer of the first capacitive two-hand control system, ensure the highest safety category according to (Cat. 4) and PL e (DIN EN ISO 13849-1). The capacitive "safeCAP" two-hand control allows heavy machinery and systems in automated production plants, such as presses and punches, to be controlled safely and without pressure.

To start the machine the user simultaneously presses two capacitive buttons which are connected to a safety relay. Incorrect or inattentive control using just one hand or with another part of the body is detected by the system and the machine is not started.

CAPTRON supplies the safeCAP two-hand control with additional safety elements such as the Protector or the control desk for tabletop installation. These combinations enhance protection and are certified to DIN EN 574. The dynamically switching SENSORswitches detect interference factors such as dirt, dust or foreign bodies. The switches can be actuated using disposable or work gloves, however.

EQP SERIES CO., LTD

Product Description :

General-purpose, low-cost vibration sensor with an integrated sensor and amplifier, and an output current ranging from 4 to 20 mA. This low-cost and straightforward vibration monitoring sensor is ideal for controlling and monitoring rotating machinery. It offers three measurement modes: displacement measurement, velocity measurement, and acceleration measurement.

Due to the 4-20 mA DC output, it can be directly connected to recorders, displays, timing circuits, and other equipment. The integrated design of the sensor and amplifier eliminates the need for a separate vibration meter amplifier. It operates on a 2-wire system, comprising power and signal lines, with no polarity considerations during connection.

By connecting to a dedicated monitor or instrument relay, it can be used as a vibration meter or vibration measuring instrument. It is also compatible with Fuji Electric's MVM series.

※Can be used in conjunction with the Model-2590C display.

LASER APPLICATION TECHNOLOGY CO., LTD.

Product Description :

◎ Tool Length Measurement

◎ Tool Radius Measurement

◎ Tool Breakage Detection

◎ Spindle Runout Analysis

◎ Three Axes Backlash Analysis

◎ Spindle Inclination Analysis

◎ Online Thermal Displacement Automatic Modeling and Compensation

DA CEI TRADE CO.,LTD.

Product Description :

Low pressure loss! Low cost! Light!

Compressor and high pressure blower are unnecessary!

Air-speed 100m/s can be discharged by the turbo-blower.

G-TECH INSTRUMENTS INC.

Product Description :

The performance of the spindle is an important key to processing quality. When you understand the performance of the spindle, you can predict and control the quality of the processed parts. The shape accuracy, roundness, and surface roughness of the workpieces are all related to the performance of the spindle. Only when the spindle is real measuring the accuracy of the spindle at the processing speed of the machine has meaning to the control of the quality of the processed parts, so measuring and understanding the performance of the machine tool, finding the best working speed, determining the warm-up time, even confirm the accuracy of the spindle after the collision.

LION provided this SEA analysis system as early as 1993 to help spindle manufacturers, machine tool factories and processing plants to reduce workpiece defect rate and improve product quality.

★The SEA system complies with the following international standards:

✓ ANSI / ASME B5.54-2005: "Methods for Performance Evaluation of CNC Machining Centers"

✓ ISO230: Test Code for Machine Tools, 3: "Determination of Thermal Effects" 7: "Geometric Accuracy of Axes of Rotation"

✓ ANSI / ASME B5.57-1998: "Methods for Performance Evaluation of CNC Turning Centers"

✓ ANSI / ASME B89.3.4: "Axes of Rotation, Methods for Specifying and Testing"