Theme

Digital Transformation

Green Transformation

HC FENG CO., LTD.

Product Description :

Replenishing Fluid automatically, accurate cutting fluid concentration. One equipment to multiple CNC machining centers. The supply line can be as long as 20 meters.

#Filtration by 3 filters #Sterilization by ozone # Oil-water mixer to precise mixing 0-10% cutting fluid #Stirring device avoid cutting fluid become stagnant water. #oil tank level meter for 50 gallon barrel low level detection.

HC FENG CO., LTD.

Product Description :

The combination of centrifugal device and magnetic separator is perfect for processing water-and oil-based cutting fluids and sludge containing magnetic dusts and shavings. The shaving removal is quick and effective, which saves a lot of time waiting and minimizes the costs to replace consumables.

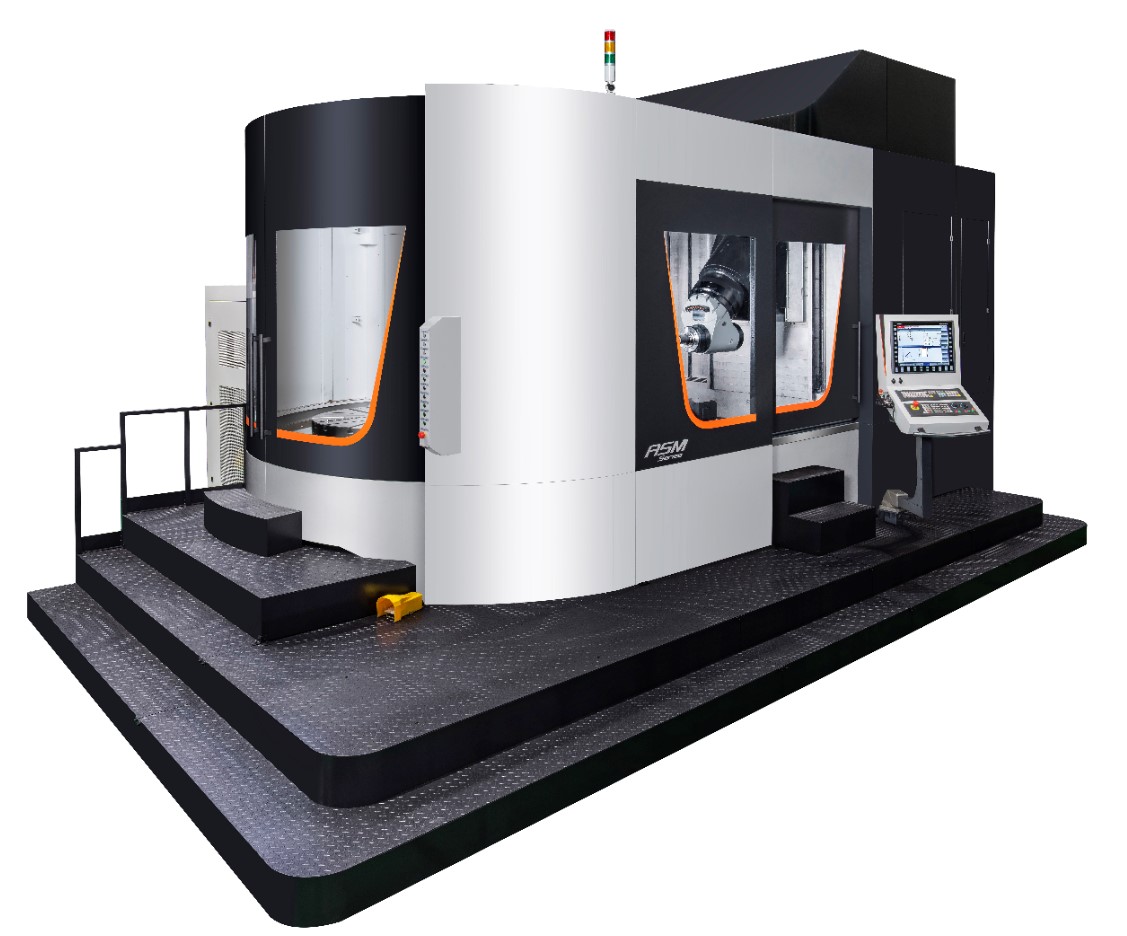

VISION WIDE TECH CO., LTD.

Product Description :

• ASM is the first 5-axis CNC turning and milling machining center of Vision Wide, and it is particularly designed for delicate cylindrical components machining featuring high acceleration, rapid feed-rate and synchronized axes machining, especially for aerospace components, tire molds, turbine blades and aluminum parts.

ASM accessorizes with 5-axis universal head and rotary shafts built-in D.D motor. Through topology analysis, ASM realizes the best distance between tool center point and B-axis transmission

• Positioning P0.006mm

• Repeatability Ps0.0055mm

• Spindle thermal compensation 0.02 mm

• Rapid Traverse 40m/min

• Acceleration 0.3G

• Cutting Feed rate 24 m/min

HEIDENHAIN CO., LTD. (TAIWAN)

Product Description :

In addition to milling operations, the TNC 640 also combines operations from milling, turning, and grinding processes. This sets the TNC 640 apart as a high-end control within its field of application. It is particularly well suited to HSC and 5-axis simultaneous machining, including on fully automated machining centers. The TNC 640 stands for perfect surface quality, exceptional accuracy, and very short machining times combined with shop-friendly operation and programming. On a milling/ turning machine with TNC 640, you machine the complete work piece on one machine in whatever sequence is needed. You can switch back and forth regardless of the machine and its axis configuration. The TNC 640 makes all necessary adjustments, e.g. switching to diameter display and setting the datum in the rotary table center. Batch Process Manager allows you to optimally plan and execute production jobs with great ease. With Batch Process Manager you can flexibly define the sequence of your jobs and, prior to machining, check to ensure that all of the required tools are available and that the NC program will run without errors.

HC FENG CO., LTD.

Product Description :

FOODIE (Chip/Sludge Removal Machine) works for :

Filtration/Removal of excess components

Chip/Sludge Removal

Fine Chip Removal

No downtime

No consumables

Backwater automatically & simultaneously

Air pressure drive w/o a plug

Vertically fast filter drying up to 90% efficiency

Precision filters effective up 20% for super filtration micro-fines

Easy to move

Filter accuracy can be adjusted

Extend cutting fluid life

REN AN INFORMATION TECHNOLOGY CO., LTD.

Product Description :

RenAn's operation simulation workstation is a physical simulation with 3D graphic, showing the cutting and machining process.

[Save consumable cost]: There is no need to worry about the expenditure of consumables, and it will not be affected by pollutants such as waste materials and oil and gas.

[Safety]: Advanced 3D simulation and CNC virtual machine make high risk CNC operation without any danger.

[Smart learning]: Like training the pilot using flight simulators, we use CNC simulator to train the students or operators to be the machinist. Its industrial panel remains the same functionality as real machine that students can practice constantly to accumulate hands-on operation skills.

The controller series of simulator: Fanuc, Siemens, Heidenhain and Mitsubishi.

Turning, Milling, TurnMill, 4 axis, 5 axis.

VISION WIDE TECH CO., LTD.

Product Description :

GSF Series 5-axis Gantry Type Machining Center, provided excellent 5-axis simultaneous accuracy performance for 5-axis machining in mold cutting, highly precise contour finishing, milling, drilling, and tapping. Vision Wide manufactured the 5-axis machining center to shorten tool displacement travel and cutting process effectively, and to extend tool lifetime and offer the best choice for composite angle machining. GSF Series had excellent dynamic performance on one-piece structural and equipped high accuracy 2-axis head to achieve 5-axis simultaneous accuracy performance.

•Continuous 2-axis head

•5 axis dynamic rotation synchronization accuracy (TCPM) 0.04mm.

•Built-in Spindle Direct-Driven on B&C axis, 12,000~24,000rpm spindle speed.

•Backlashless driving on B/C axis,Rotation Positioning accuracy ±5”.

•Low table height, closer operating zone, wider door width are convenient design for user.

•Chain type chip conveyor (standard) is able to remove iron chips efficiently.

CHIEN CHENS MACHINERY CO., LTD.

Product Description :

Specification

Table size: 1515 x 470 mm

Longitudinal travel: 1300 mm

Cross travel: 600 mm

Y slide way width: 720 mm

Z Slide high: MAX 810 mm

Z Slide way width: 420 mm

Spindle taper: NT#40(BT)

Spindle motor: 5HP / 4P

Spindle speed: 70~3600 RPM

Feeding speed: 10~6000 mm/min

Ballscrew: Ø32 mm C5

Net weight: 3500 kgs