Theme

Digital Transformation

Green Transformation

YEONG CHIN MACHINERY INDUSTRIES CO., LTD.

Product Description :

Most Popular High Performance NSV106AS is well suited for superior surface finishing works, specially in automotive, job shop and electronics industries. ■ Large delta machine column and base ensure the highest stability during high speed movement■ High precision roller type guideways on all 3 axes■ High precision linear guideway with 6 slide blocks on X-axis■ High performance YCM in-house designed spindle with low vibration to achieve excellent finish

YEONG CHIN MACHINERY INDUSTRIES CO., LTD.

Product Description :

NFX400A is designed especially for small, complex high-quality parts mainly for aerospace, automotive, medical, job shop and die & mold applications

■ Extra wide column and base design to ensure best support and cutting rigidity.

■ Increased tool life by cutting with belly and edge of the tool

■ Reduce fixture error and improve workpiece loading and uploading time

■ Greatly reduced non-cutting or setup waiting time

■ Saves manufacturing cost with reduced fixture and electrode costs.

BUFFALO MACHINERY CO., LTD.

Product Description :

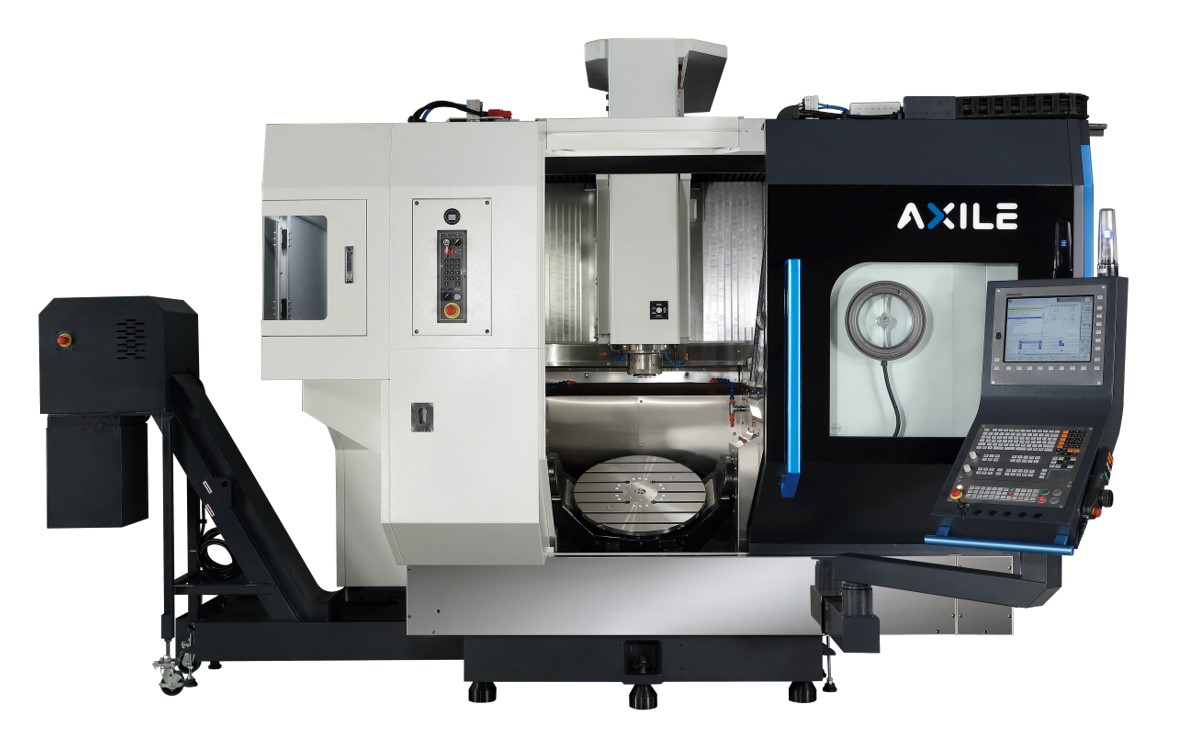

With a rotary table diameter of 600 mm, the G6 is a compact vertical machining center designed for agile, smart machining of smaller workpieces requiring complex geometries and intricate features. This highly versatile VMC delivers full 5-axis CNC machining, with the built-in spindle moving along the X,Y,Z-axis, and the table moving in rotary C-axis and swiveling A-axis.

The G6’s perfect balance of speed and precision makes it the perfect option for job shops and production lines seeking an upgrade in machining capabilities, delivering high removal rates, excellent surface finishes, and maximum production efficiency.

In addition to the high-performance G6 model, AXILE also offers the G6 MT, which combines both milling and turning in one machine, greatly increasing operational flexibility. By reducing set-up times and potential clamping errors, the G6 MT can efficiently machine a wider variety of parts, including cylindrical components.

VISION WIDE TECH CO., LTD.

Product Description :

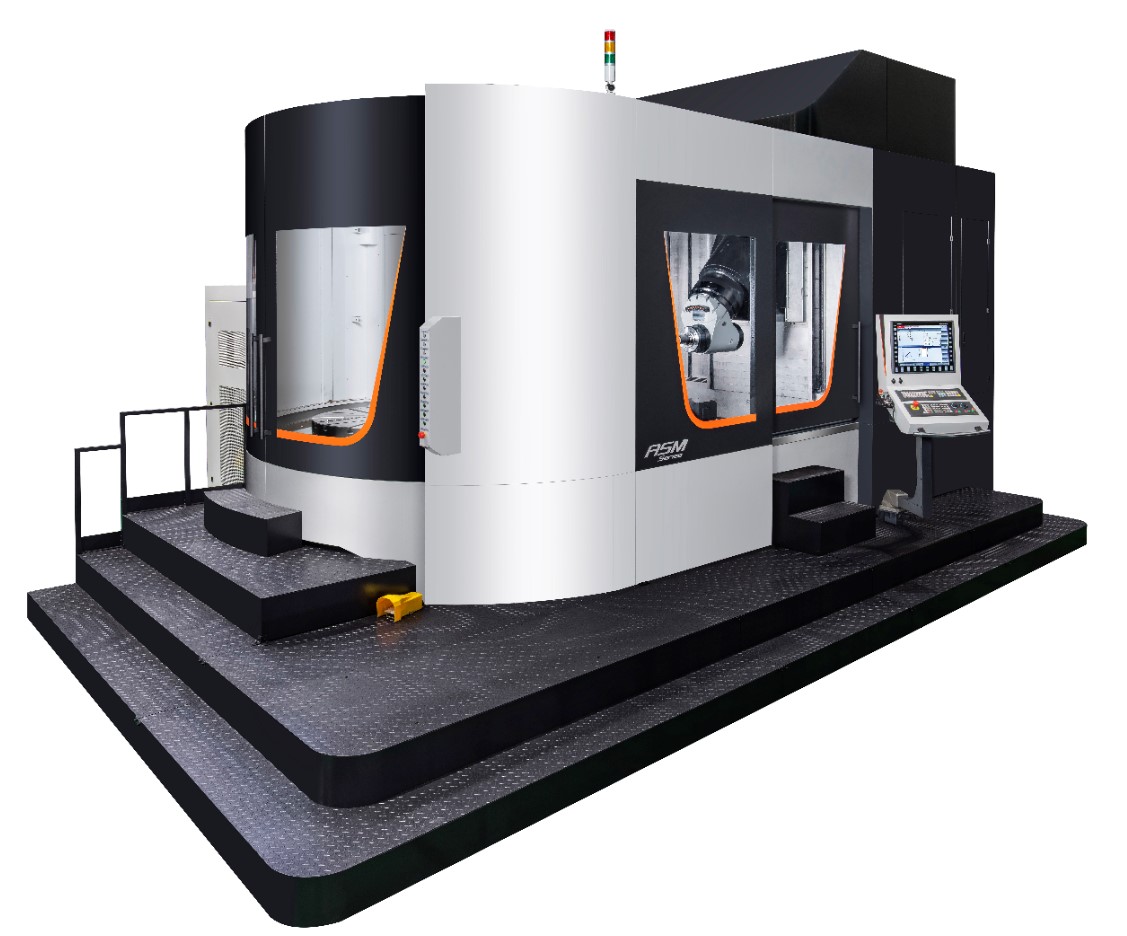

• ASM is the first 5-axis CNC turning and milling machining center of Vision Wide, and it is particularly designed for delicate cylindrical components machining featuring high acceleration, rapid feed-rate and synchronized axes machining, especially for aerospace components, tire molds, turbine blades and aluminum parts.

ASM accessorizes with 5-axis universal head and rotary shafts built-in D.D motor. Through topology analysis, ASM realizes the best distance between tool center point and B-axis transmission

• Positioning P0.006mm

• Repeatability Ps0.0055mm

• Spindle thermal compensation 0.02 mm

• Rapid Traverse 40m/min

• Acceleration 0.3G

• Cutting Feed rate 24 m/min

BUFFALO MACHINERY CO., LTD.

Product Description :

The DC12 is the most robust VMC in AXILE’s arsenal, perfectly suited for handling larger, lengthy workpieces. With a maximum table loading weight of 2.5 tonnes and maximum diameter of 2,200 mm X 1,200 mm, the DC12 takes on the larger, heavier parts common in the aerospace, power generation, and die and mold industries. Its double-column bridge construction allows for greater rigidity, as well as greater control over thermal deformation. As a result, the D12 is capable of deep cuts and complex contouring while maintaining utmost precision.

With larger workpieces come more chips, meaning the DC12 features excellent chip removal efficiency, to prolong tool life and ensure no residual interference. Therefore, the DC12 delivers the high surface quality expected by leading manufacturers.

ASIA PACIFIC ELITE CORP.

Product Description :

G800T,a single machine completes all cutting processing.

The APEC 5-axis mill-turn machining center G800T is built with a vertical structure to tackle the limitations faced by traditional lathe machining. After turning, it seamlessly transitions into milling without having to move the workpiece, cutting down on time and human errors. This means you can complete the job in one go without switching processes, leading to a more efficient and modern machining experience.