Theme

Digital Transformation

Green Transformation

HEIDENHAIN CO., LTD. (TAIWAN)

Product Description :

In addition to milling operations, the TNC 640 also combines operations from milling, turning, and grinding processes. This sets the TNC 640 apart as a high-end control within its field of application. It is particularly well suited to HSC and 5-axis simultaneous machining, including on fully automated machining centers. The TNC 640 stands for perfect surface quality, exceptional accuracy, and very short machining times combined with shop-friendly operation and programming. On a milling/ turning machine with TNC 640, you machine the complete work piece on one machine in whatever sequence is needed. You can switch back and forth regardless of the machine and its axis configuration. The TNC 640 makes all necessary adjustments, e.g. switching to diameter display and setting the datum in the rotary table center. Batch Process Manager allows you to optimally plan and execute production jobs with great ease. With Batch Process Manager you can flexibly define the sequence of your jobs and, prior to machining, check to ensure that all of the required tools are available and that the NC program will run without errors.

REN AN INFORMATION TECHNOLOGY CO., LTD.

Product Description :

1. Production progress control

2. Finish time estimate

3. Cutting Feedrate Verify monitoring

4. Machine alarm notification

REN AN INFORMATION TECHNOLOGY CO., LTD.

Product Description :

Guided-steps CAD/CAM with Machining Simulation including tool path verification and machining time.

Excellent tool for learning CAD/CAM and verifying with simulation.

JIUH-YEH PRECISION MACHINERY CO., LTD.

Product Description :

1. 高剛性的立柱 2.高精密旋轉工作台(0.001度) 3.高壓沖屑裝置 4.螺桿中空冷卻系統。 5.全密閉式外罩,低噪音,防止漏水。 6.結合面接採用鏟花精密製造。

HEIDENHAIN CO., LTD. (TAIWAN)

Product Description :

Collision protection is a major topic at HEIDENHAIN. The touch probes feature a large deflection path and offer additional safety with rated breaking points in the stylus or the connecting pin to the probe contact.

The TS 460 and TT 460 touch probes feature intelligent battery management in order to minimize current consumption. The touch probe switches in steps to the stand by condition: The longer a touch probe has been switched off, the less current it consumes. Activating a touch probe from a low standby level takes only a split second longer. This ensures high, application oriented availability.

REN AN INFORMATION TECHNOLOGY CO., LTD.

Product Description :

RenAn's operation simulation workstation is a physical simulation with 3D graphic, showing the cutting and machining process.

[Save consumable cost]: There is no need to worry about the expenditure of consumables, and it will not be affected by pollutants such as waste materials and oil and gas.

[Safety]: Advanced 3D simulation and CNC virtual machine make high risk CNC operation without any danger.

[Smart learning]: Like training the pilot using flight simulators, we use CNC simulator to train the students or operators to be the machinist. Its industrial panel remains the same functionality as real machine that students can practice constantly to accumulate hands-on operation skills.

The controller series of simulator: Fanuc, Siemens, Heidenhain and Mitsubishi.

Turning, Milling, TurnMill, 4 axis, 5 axis.

HC FENG CO., LTD.

Product Description :

Replenishing Fluid automatically, accurate cutting fluid concentration. One equipment to multiple CNC machining centers. The supply line can be as long as 20 meters.

#Filtration by 3 filters #Sterilization by ozone # Oil-water mixer to precise mixing 0-10% cutting fluid #Stirring device avoid cutting fluid become stagnant water. #oil tank level meter for 50 gallon barrel low level detection.

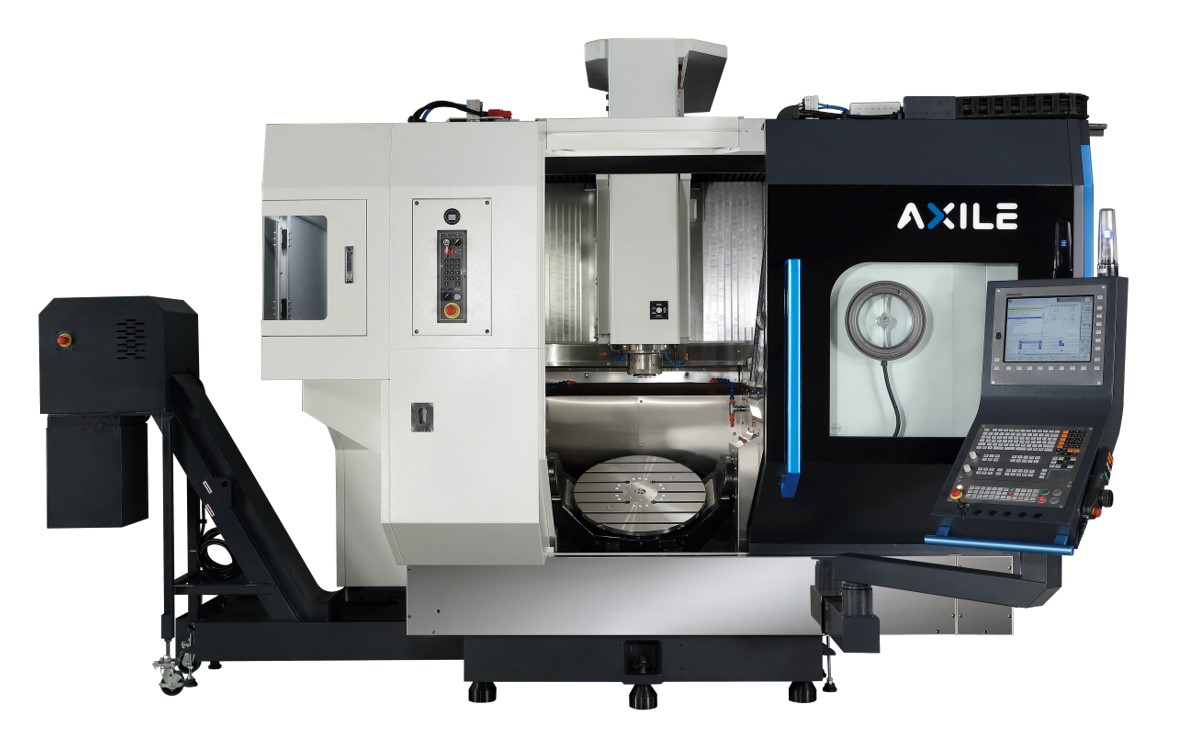

BUFFALO MACHINERY CO., LTD.

Product Description :

With a rotary table diameter of 600 mm, the G6 is a compact vertical machining center designed for agile, smart machining of smaller workpieces requiring complex geometries and intricate features. This highly versatile VMC delivers full 5-axis CNC machining, with the built-in spindle moving along the X,Y,Z-axis, and the table moving in rotary C-axis and swiveling A-axis.

The G6’s perfect balance of speed and precision makes it the perfect option for job shops and production lines seeking an upgrade in machining capabilities, delivering high removal rates, excellent surface finishes, and maximum production efficiency.

In addition to the high-performance G6 model, AXILE also offers the G6 MT, which combines both milling and turning in one machine, greatly increasing operational flexibility. By reducing set-up times and potential clamping errors, the G6 MT can efficiently machine a wider variety of parts, including cylindrical components.

ASIA PACIFIC ELITE CORP.

Product Description :

G800T,a single machine completes all cutting processing.

The APEC 5-axis mill-turn machining center G800T is built with a vertical structure to tackle the limitations faced by traditional lathe machining. After turning, it seamlessly transitions into milling without having to move the workpiece, cutting down on time and human errors. This means you can complete the job in one go without switching processes, leading to a more efficient and modern machining experience.