Theme

Digital Transformation

Green Transformation

ASMITH MANUFACTURING COMPANY

Product Description :

Spring Loaded Draw Latch |The proposed load of 22~50 kgf.

Both sides spring design with compression function.

Standard Lock-hole can using with lock. Suitable for vibration equipment.

Smooth surface, excellent brushed finish appearance, in accordance with RoHS.

The draw latch is including the horizontal keeper [CS(T)-0120-2 or CS(T)0130-2], if you need another type keeper then you can reference the below "Accessories".

➤Material: SUS304(Stainless steel)-vibration ground and brushed finish, SPCC(cold-rolled steel)-zinc plated

YIH KUAN ENT CO., LTD.

Product Description :

The Plano Milling Head (Gantry Milling Head) are commonly used milling machine heads such as gantry milling machines, boring milling machines, and double-head milling machines. Uses include rough milling, finishing milling, boring holes... and other processing requirements.

The left and right vertical milling heads offer excellent flexibility and adaptability. Their adjustable angles and swivel capabilities enable operators to perform angular milling, drilling, and other complex operations with ease. They are compatible with different milling machines, providing a seamless integration into existing setups or as a valuable addition to new milling machine installations.

1. IK milling heads can upgrade or replacement your existing machine body, milling machine or special machine and also it can bring more stable and high-quality machining benefits for work piece cutting.

2. It is used for mold manufacturing or precision processing.

3. The machine processing for travel is 320 mm. We also provide “No slide” format.

4. This product is used in Gantry (Plano) Milling Machine (vertical / horizontal), suitable for heavy metal cutting.

5. Plano milling head series offer accessory head for you to optional.

It will apply for multi-angle machining to upgrade efficiency and longer machining range.

6. This product of standard motor is 10HP. We also offer 12.5HP for you to optional.

7. Offer pneumatic blade locking device, bearing guide screw, pneumatic leveler for you to optional.

8. There are 10 models in IK Plano Milling Machine Head Series.

CLAMPTEK ENTERPRISE CO., LTD.

Product Description :

Clamptek’s CLF5H series designed with connecting rod structure which can operate conveniently. CLF5H series can also reduce the interference with loading and unloading operation, because when CLF5H series is in the unclamping state, it’s clamping arm can be put lower than holding position.

Clamptek’s CLF5H series’ clamping arm is very flexible. By reducing the interference of the surrounding equipment, CLF5H series can save lots of working space.

Clamptek’s CLF5H series equipped with special dust proof design and high sealing, which can prevent the cutting chips and coolant to infiltration. Therefore, CLF5H series can be used in more severe conditions.

Please kindly check the suggested operating pressure as below,

Max. operating pressure: 70 kgf/cm2

Min. operating pressure: 10 kgf/cm2

YOKE INDUSTRIAL CORP

Product Description :

1. Size from M8 to M90 to fulfill your demand

(M8 ※ 0.3t _ M90 ※ 40t)

2. Design Factor 4:1, Working load limit could be up to 40 tons

3. Lifting point is made by forged alloy steel, quenched and tempered

4. Suitable for all loads which swivel and tilt especially for heavy duty, material handling, mold & die industries.

5. Ball bearing inside is easier for flipping working piece and rotation.

6. Light weight, High Performance, easily for using

7. Deliver with test certification to guarantee your safety

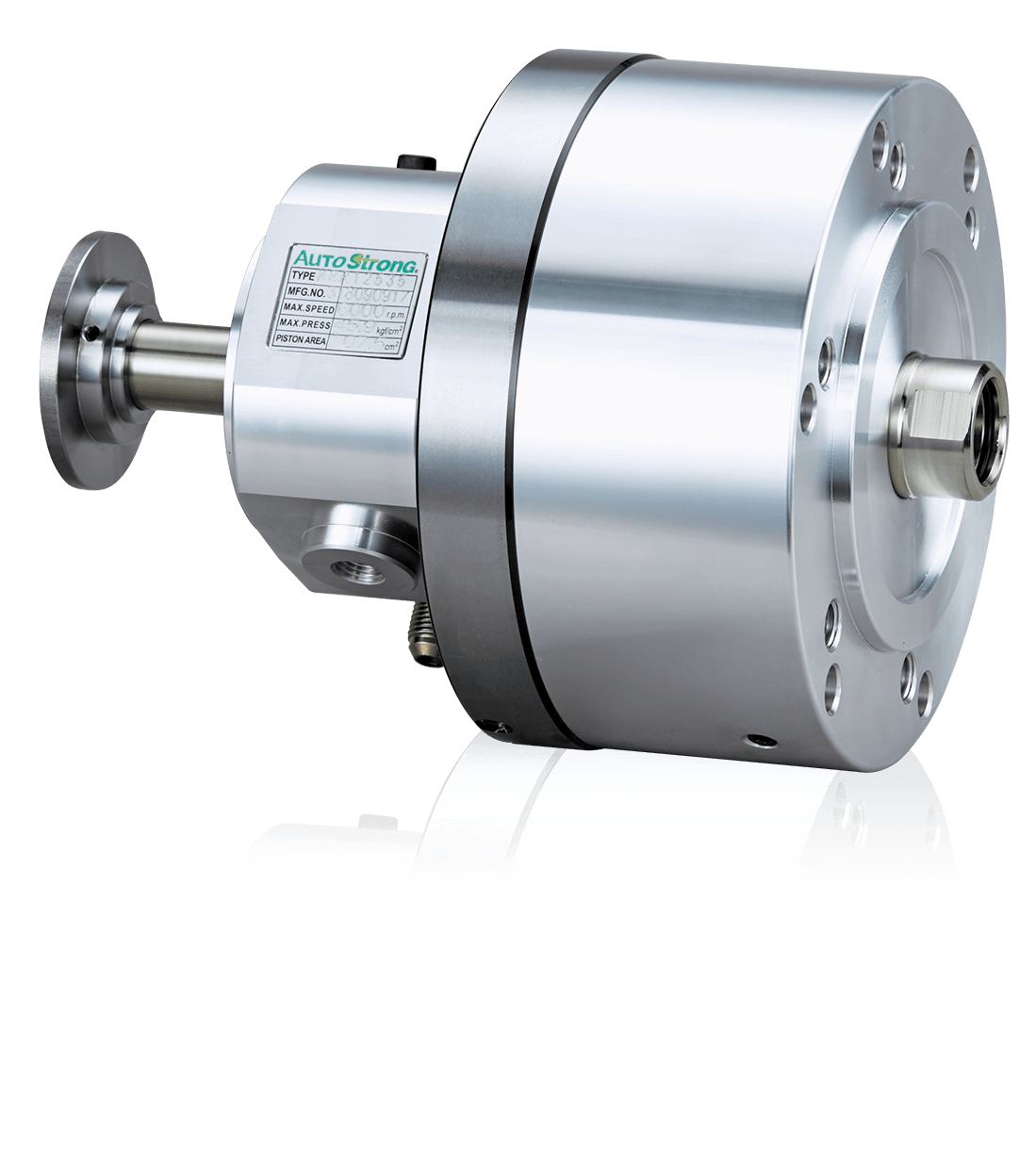

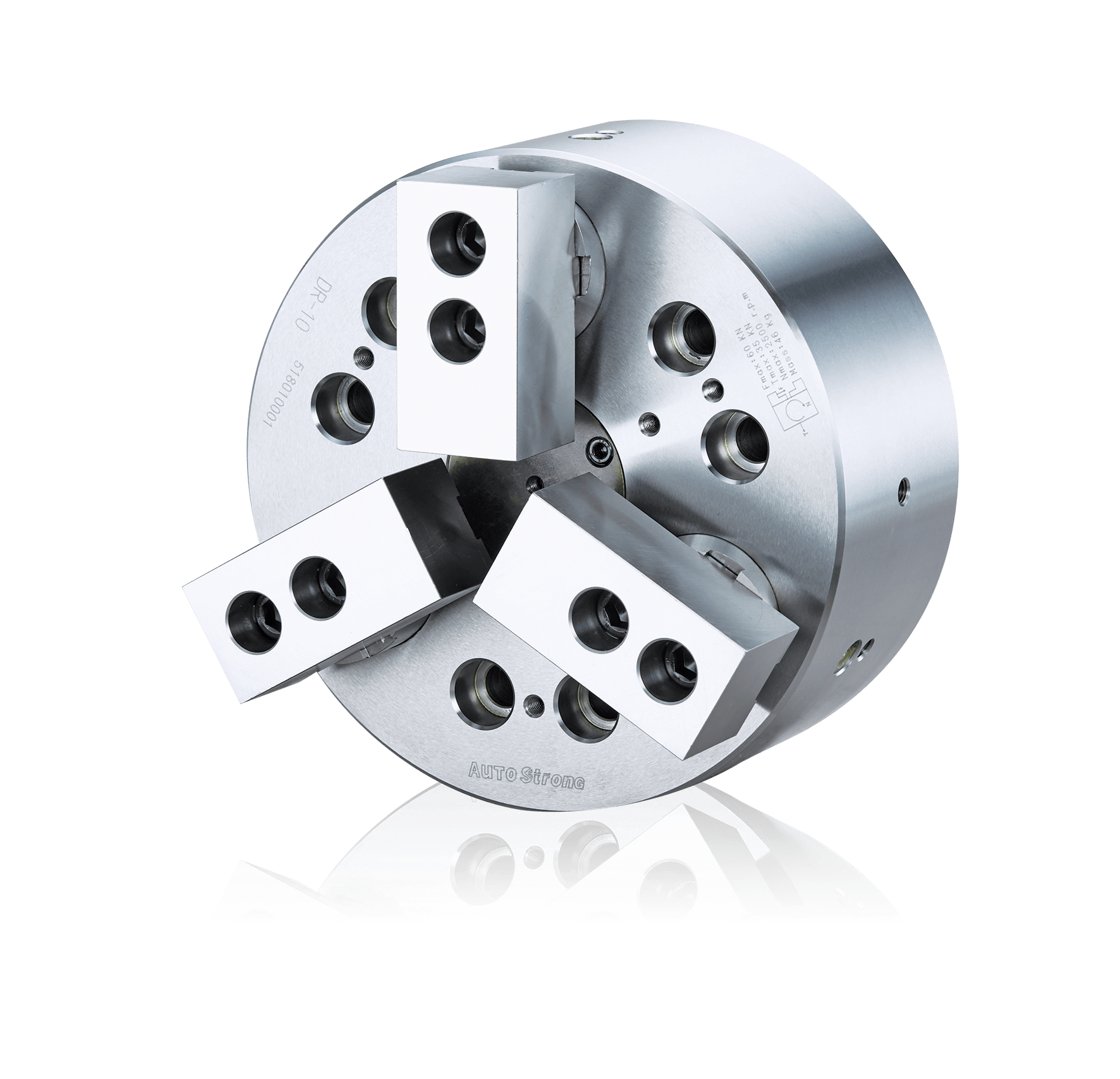

DI CHUN IRON WORK CO., LTD.

Product Description :

Drawdown power chuck feature of radial clamping will lead to almost no workpiece uplifting displacement; for machining casting and forging part:

1. For the clamped workpiece is oppressed to the surface, chucks are suitable for heavy machining.

2. Chuck Actuators with the cylindrical structure is durable and ensures high clamping repeatability.

3. Accurate self-centering and pull back features are adequate or precise length control machining requirements.