Theme

Digital Transformation

Green Transformation

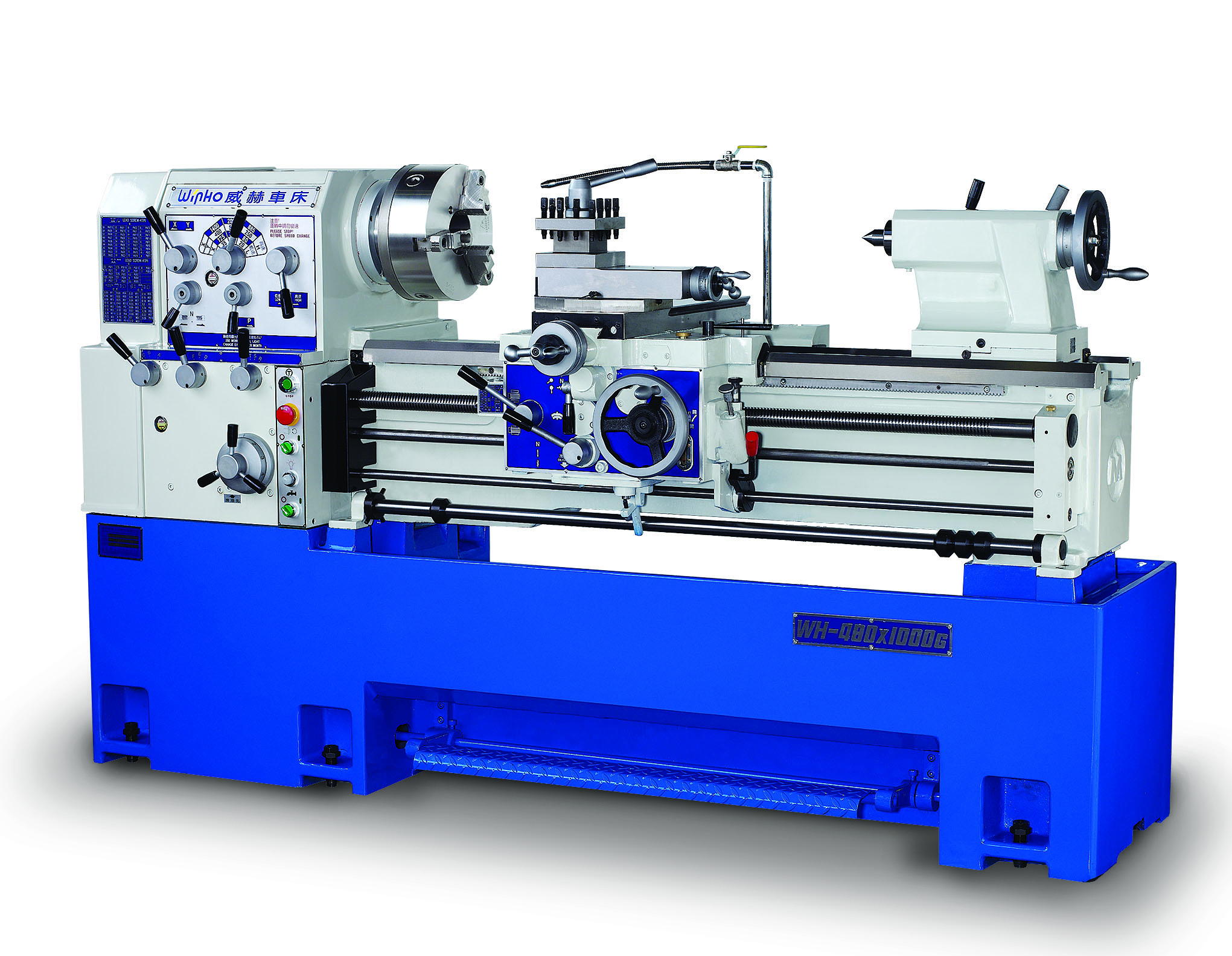

WIN HO TECHNOLOGY INDUSTRIAL CO., LTD.

Product Description :

High Speed Precision Lathe

1. Selective bed width:

S series: 300mm.

M series: 350mm.

L series: 400mm.

2. Varied spindle bore diameters:

S series: O58mm / O80mm (Option).

M series: O85mm / O105mm (Option).

L series: O85mm / O120mm (Option).

3. With FAG or SKF precision bearings installed on

spindle, maximum cutting depth can be 8mm on

50mm diameter and best roundness 0.003mm

(200mm long).

4. Equipped with plastic rear gears, shafts and

gears inside headstock are well protected if crash

should occur (S430 & S480 Series).

5. Thermal treated and precision ground alloy

gears.

6. Universal gearbox for both imperial and metric

thread-conversion table also attached.

7. Tracks of cross slide and bed are well lubricated

with lubrication pump (manual).

8. Overload device to ensure safety when

operating.

9. Wear-resistant phosphor bronze lead screw

nuts.

10. Durable reservoir oil bath type cross slide (for S

series).

11. Thermal treated Meehanite bed casting.

12. One-piece base for high rigidity and low

vibration.

13. High-capacity coolant tank offers sufficient

coolant output.

14. All series certified for CE.

Reservoir Oil Bath Type Cross Slide

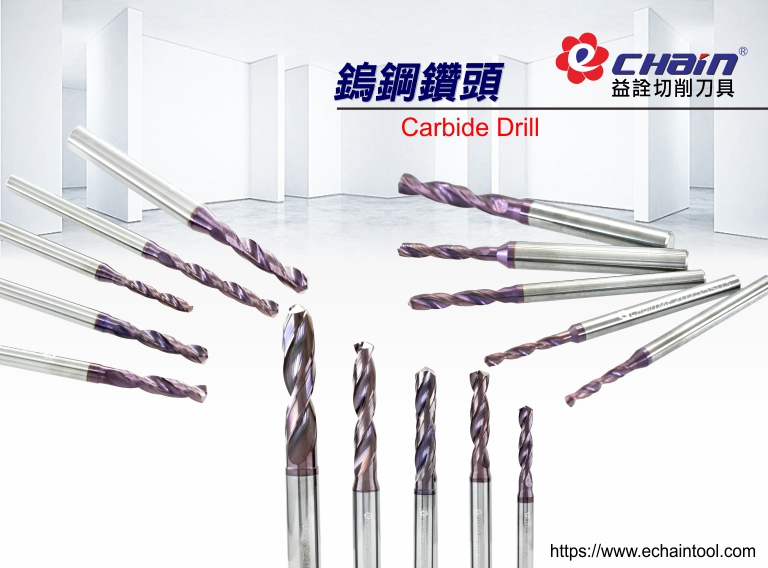

ECHAINTOOL PRECISION CO., LTD.

Product Description :

"鎢鋼鑽頭為益詮2020年全新上市主力產品,採用國外進口五軸刀具研磨機生產製造,研磨尺寸精準且穩定,提供高品質鎢鋼鑽頭服務。

產品特色:

(1)鎢鋼刀體為含鈷量12%超微粒硬質合金,高剛性耐磨耗耐高溫,可以加工切削HRC<55°工件(2)鑽尖結構加強優化設計,提升切削排屑性能(3)獨特雙刃帶設計,提升加工穩定性,可增加切削加工使用時間(4)全新AlTin鍍鈦塗層,泛用性廣可適用:合金鋼、不鏽鋼、鑄鐵加工。

益詮精密專業製造:(1)捨棄式車刀:新增中心出水外徑車刀架和中心出水內徑車刀架(2)捨棄式铣刀:新增捨棄式粗铣刀、捨棄式T形槽铣刀(3)捨棄式刀片:整合各式車刀片及铣刀片新材質開發(4)鎢鋼端铣刀:新增鎢鋼鑽頭,極小徑鎢鋼一體式車刀,開發新鎢鋼圓棒及特殊研磨刃口端铣刀。

為因應廣大市場需求,益詮精密持續開發精進新增所有刀具品項,不斷努力提升產品品質和服務,秉持初衷努力不懈進步成長,生產製造以最高品質要求,期盼能成為台灣製造業的後盾。"

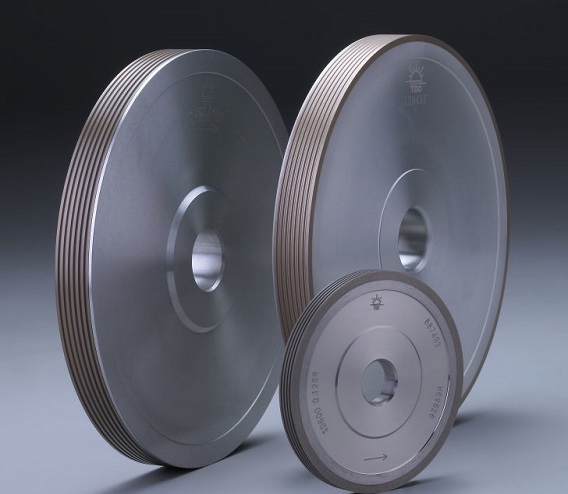

TAIWAN ASAHI DIAMOND INDUSTRIAL CO., LTD.

Product Description :

* Processing Method|Grinding

* Applications|Semiconductor Material Processing

* Silicon wafer edge grinding wheels require strict shape precision and wear resistance, and require stable grinding capabilities, so metal bond grinding wheels can be used. We can provide single groove or multi groove, integrated coarse and fine grinding wheel according to customer’s requirements.

* Processing Material | Silicon Crystal

FUTECH PRECISION CO.,LTD.

Product Description :

FUL series CNC Lathe is to enhance high speed and high accuracy. 45 degree slant bed construction features high rigidity and high stability.

X、Z axis are mounted with ball type linear guide ways or box guide ways. Axis movement is directly driven by a servo motor , allowing the high rapid traverse rates on X、Z axis.

JARNG YEONG ENTERPRISE CO., LTD.

Product Description :

This model can work with two axes gantry loader to transform CNC lathe be automation which is in order to accomplish automatic catching single blank material, uploading, unloading and clamping manufacture progress to increase physical labor productivity.

The most advantage is we can stand on the customer’s machining demand to choose the different types of feed stations.

VISION WIDE TECH CO., LTD.

Product Description :

• Patent design high-pressure coolant system up to 125 bar

• Turning 75Kw

• Vertical milling

• Grinding

• Turning-Milling ATC

YING HAN TECHNOLOGY CO., LTD.

Product Description :

5-AXIS VERTICAL MACHING CENTER BELONGS LINEAR WAYS ON THREE AXES, X, Y, Z -AXIS TRAVEL: 800x600x550mm, MEEHANITE CAST IRON IS TEMPERED FOR STRESS RELIEF TO ENSURE STRUCTURAL STABILITY WITHOUT DEFORMATION. REINFORCED COLUMN BASE GREATLY INCREASES STRUCTURAL STRENGTH AND WILL EXHIBIT ULTRA-HIGH STABILITY DURING HIGH SPEED OPERATION. WITH THE EQUIPMENT OF CNC TILTING ROTARY TABLE, THE MACHINE IS ABLE TO PERFORM 5-AXIS MACHINING, IT CAN MACHINE COMPLEX, MULTI-SIDED PARTS IN A SINGLE SETUP, THEREBY REDUCING SETUP TIME WHILE INCREASING PART ACCURACY.

MING YANG MACHINERY CO., LTD.

Product Description :

This heavy duty multi-tasking turning center is an advanced and economical solution designed to process precision complex parts with fast cycle times.

Power & Versatility: It has Double Spindles, a BMT 12 station turret and 4 gang tools for economical machining. Coupled with superimposed cutting it’s a powerful solution for precision complex workpieces with extremely fast cycle times.

Front Machining: BMT 45, 12 Stations, Up to 24 Tools, 7.5/11 kW Spindle Power, 55 mm Through Hole

Back Machining: GT42: 4 x 20 mm ID Tools, GT52: 4 x 16 mm ID Tools, Or 3x 20 mm ID Tools, Or 3x 25 mm ID Tools

JARNG YEONG ENTERPRISE CO., LTD.

Product Description :

1. High rigidity body structure, machine base casting is integrally formed and high rigidity linear guide way, providing stabler, faster and higher precision.

2. Built-in main spindle is with C-axis function, high speed, big power, high precision and low vibration which can make surface of workpiece smoother.

3. Optional:Synchronous rotary guide bushing device, it's suitable for processing long workpiece which can reduce cycle processing time and improve production efficiency.

4. Sub-spindle is with C-axis function, it can work with live tooling for end side drilling, tapping and milling.

5. It can depend on different demand of machining to with or without Synchronous rotary guide bushing device.

6. Axes:Z1/X1/Y/C1/Z2/X2/C2 + 3 sets of live tooling devices (A/B1/B2)

7. Max. 23 tools, can do machining on front side and back side at the same time which can save time for processing.

8. With guide bush type travel is 180mm, min. offal is 150mm. Without guide bush type travel is 310mm, min. offal is 50mm.

SONG GIA INDUSTRIAL CO., LTD.

Product Description :

●精密鉸孔神器-浮動鉸刀柄,可解決以下問題:

1. 孔的直線行差

2. 鉸刀不耐用

3. 孔的尺寸擴大,尺寸精度達不到要求

4. 孔的中間大,兩頭小,圓柱度達不到要求

5. 內孔表面粗糙度達不到要求

6. 大批生產時無法保證孔徑尺寸的一致性 。

●浮動鉸刀柄的特點:

1.可透過360度浮動讓鉸刀對準下孔徑,避免對不準而造成擴孔或縮孔

2.徑向振幅抑制在5μm以下

3.提高鉸孔光潔度

4.彌補車床公差,提高鉸孔精密度

5.提高鉸孔的直線度和圓柱度

●浮動鉸刀柄可應用加工機械:鑽床、立式加工中心、研磨機。 可夾持工具:鉸刀、滾光刀

**產品連結→→https://www.songgia.com.tw/tw/products/other-tools/floating-reamer-holder

REN AN INFORMATION TECHNOLOGY CO., LTD.

Product Description :

Just like the real CNC machine, equipped with exactly same overall appearance, actual handwheel and real machine operation panel as numerical control machine.

Solving the difficulties of real machine: precise, complicated and very expensive.

With CNC Simulator, everyone can learn CNC machine operation and accumulate hands-on operation skills.

CNC training machine is equipped with exactly same overall appearance, actual handwheel and real machine

operation panel as numerical control machine. Its purpose is to train students for accumulating CNC machine operation skills (program transmission, programming, tool selection, tool compensation and alarm clear )

Overall design is more attractive, and it emphasizes on interaction to make students less mistakes happened.

Not only decreasing learning cost but also letting students work and learn in the safe environment.