Theme

Digital Transformation

Green Transformation

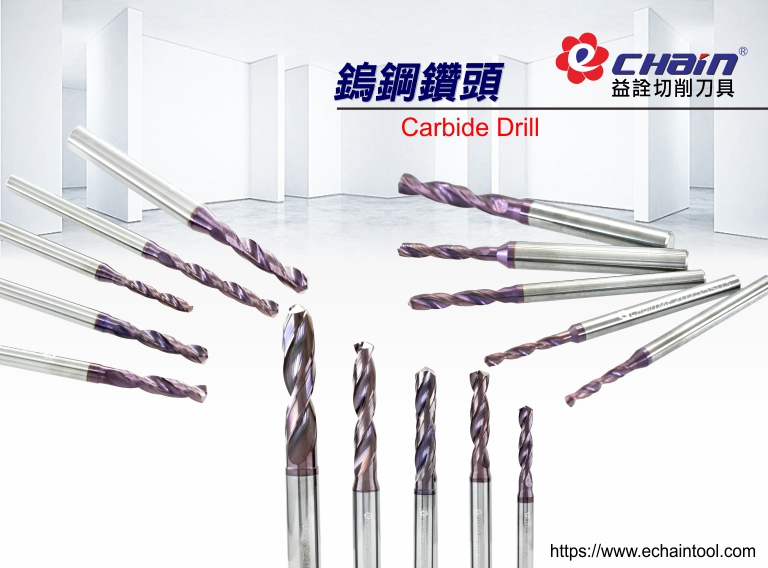

ECHAINTOOL PRECISION CO., LTD.

Product Description :

"鎢鋼鑽頭為益詮2020年全新上市主力產品,採用國外進口五軸刀具研磨機生產製造,研磨尺寸精準且穩定,提供高品質鎢鋼鑽頭服務。

產品特色:

(1)鎢鋼刀體為含鈷量12%超微粒硬質合金,高剛性耐磨耗耐高溫,可以加工切削HRC<55°工件(2)鑽尖結構加強優化設計,提升切削排屑性能(3)獨特雙刃帶設計,提升加工穩定性,可增加切削加工使用時間(4)全新AlTin鍍鈦塗層,泛用性廣可適用:合金鋼、不鏽鋼、鑄鐵加工。

益詮精密專業製造:(1)捨棄式車刀:新增中心出水外徑車刀架和中心出水內徑車刀架(2)捨棄式铣刀:新增捨棄式粗铣刀、捨棄式T形槽铣刀(3)捨棄式刀片:整合各式車刀片及铣刀片新材質開發(4)鎢鋼端铣刀:新增鎢鋼鑽頭,極小徑鎢鋼一體式車刀,開發新鎢鋼圓棒及特殊研磨刃口端铣刀。

為因應廣大市場需求,益詮精密持續開發精進新增所有刀具品項,不斷努力提升產品品質和服務,秉持初衷努力不懈進步成長,生產製造以最高品質要求,期盼能成為台灣製造業的後盾。"

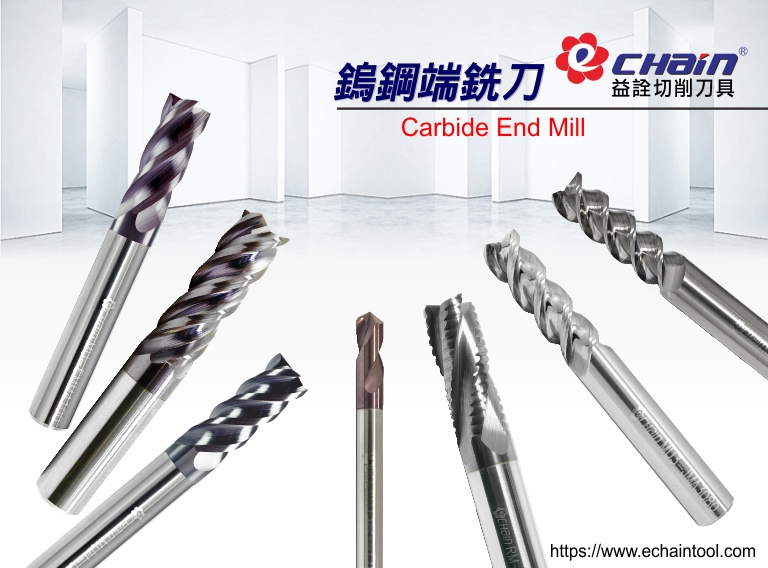

ECHAINTOOL PRECISION CO., LTD.

Product Description :

"Recently, in response to market demand, we have developed a number of new carbide end mills, starting with the "" Unequal split and Unequal spiral Carbide end mills"" (MUH-IMM Series) and "" Unequal split of Carbide end mills "" ( MUH-GMM series).

The two carbide end mills can enhance the vibration generated by the processing and increase the smoothness of the machined surface through the division ratio of the cutting edge. The unequal spiral design of the MUH-IMM series can strengthen the tool during high-speed machining. Anti-cracking; both carbide end mills have a special round groove design, which can effectively control the chip removal frequency during the plunge milling process.

In order to meet the market's processing requirements for aluminum alloys, copper and other materials, we also published the ""three-flute round land three-relief aluminum carbide end mills"" (MU3-JMA series): the cutting edge of the carbide end mills adopts three clearances. Grinding, improve cutting performance, have a better processing surface, round groove full polishing treatment, effectively suppress the heat generated during processing, make the chip breaking stable, smooth chip removal, and extend the processing life.

Regardless of the products such as turning tools, milling cutters, carbide end mills or accessory sleeves, ECHAINTOOL team has continuously developed and innovated, developed various specifications, and the first-hand new product release information is visible to the official fan group (HTTPS). ://www.facebook.com/

Phone: +886-04-2271-0856

"

MING YANG MACHINERY CO., LTD.

Product Description :

This heavy duty multi-tasking turning center is an advanced and economical solution designed to process precision complex parts with fast cycle times.

Power & Versatility: It has Double Spindles, a BMT 12 station turret and 4 gang tools for economical machining. Coupled with superimposed cutting it’s a powerful solution for precision complex workpieces with extremely fast cycle times.

Front Machining: BMT 45, 12 Stations, Up to 24 Tools, 7.5/11 kW Spindle Power, 55 mm Through Hole

Back Machining: GT42: 4 x 20 mm ID Tools, GT52: 4 x 16 mm ID Tools, Or 3x 20 mm ID Tools, Or 3x 25 mm ID Tools

JINN FA MACHINE INDUSTRIAL CO., LTD.

Product Description :

Max. turning diameter 32mm ~ 42mm.<br />

<br />

Max eight axes simultaneously movement (X1/Y1/Z1/X2/Y2/Z2/C1/C2).<br />

<br />

Sub tooling system can make eccentric drilling, milling and grooving function.<br />

<br />

Side drilling can be converted to end drilling (six for front & six for back).<br />

<br />

Rigid structure with powerful lives tools brings you stable and versatile machining performance.

JARNG YEONG ENTERPRISE CO., LTD.

Product Description :

1. External auto loading/unloading SPM

2. Its feeding capabilities are O.Dφ6~φ35 mm, max length 40mm.

3. Its feeding mechanism is placed outside of machine to keep mechanism from chips and oil stain.

4. Adjustable guideway is suitable for round/hex shape workpiece alone with rotary cylinder and fixture, which can make hex material positioning in short time.

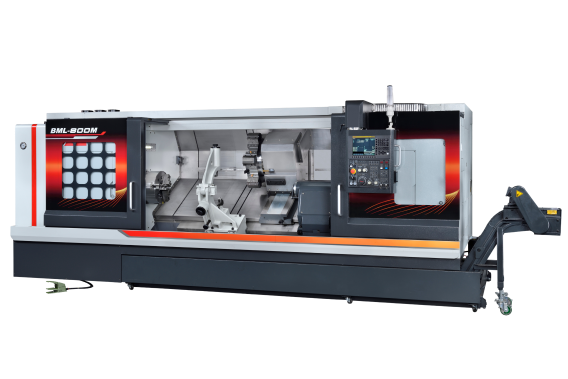

YIDA PRECISION MACHINERY CO., LTD.

Product Description :

The (B)ML-800 series is a highly customizable turning center with various options for spindle, gearbox, base, tailstock, turret and multiple selectable feed speeds. It can efficiently handle the most demanding machining requirements.

1. The modular structure design of the base has high strength and rigidity. It is molded as a single unit, effectively absorbing the vibrations generated by the machining and providing the stability and precision required for heavy cutting operations, without any distortion or deformation.

2. The optimal modular design spindle features high speed and power, and can be paired with a high-torque output gearbox design, offering a variety of processing options to meet different machining needs.

3. The robust toll turret design allows for quick and reliable tool changes, ensuring high efficiency and precision. It caters to the characteristics of various cutting processes, effectively enhancing machining capabilities.

3. The high-strength design of the transmission structure ensures precise positioning and greatly enhances machining efficiency and stability.

4. Ergonomically designed interface makes operation easy and maintenance convenient. Sheet metal design incorporates comprehensive safety considerations.

LIS AUTOMATIC CONTROLLED CO., LTD.

Product Description :

The PJ-20S is a fixed volume medium pressure system without tank designed. Suitable for a general manufacturing environment, designed for Swiss lathes.

-modular PCB, easy to maintenance

-intuitive control panel, easy to operation

-3 sets of M code output

-compact size, saving space

CAMPRO PRECISION MACHINERY CO., LTD.

Product Description :

Campro spares no effort to develop intelligent manufacturing; fully demonstrating its determination from Industry 3.0 to 4.0, Campro not only has successfully launched CAMPRO IIoT system in line with Industry 4.0 elements in 2016, but also developed its CAMPRO Smart FMS system in 2018. Through flexible manufacturing system, digital control and automated NC program and machine assignment that it can quickly react in case of changes and respond to market demand. In addition, CAMPRO also develops, CAMPRO TOOLING MANAGEMENT SYSTEM, a proprietary system combined with precision tooling/material cabinet to assist customers in managing and analyzing tooling/material usage, 24 hours to get tools or materials and early-warning or alert notifications. In some cases, the fact is increasing automation can improve worker safety and the flexible automation processing is sufficient enough to cope with complex manufacturing processes.

FUTECH PRECISION CO.,LTD.

Product Description :

FUL series CNC Lathe is to enhance high speed and high accuracy. 45 degree slant bed construction features high rigidity and high stability.

X、Z axis are mounted with ball type linear guide ways or box guide ways. Axis movement is directly driven by a servo motor , allowing the high rapid traverse rates on X、Z axis.