Theme

Digital Transformation

Green Transformation

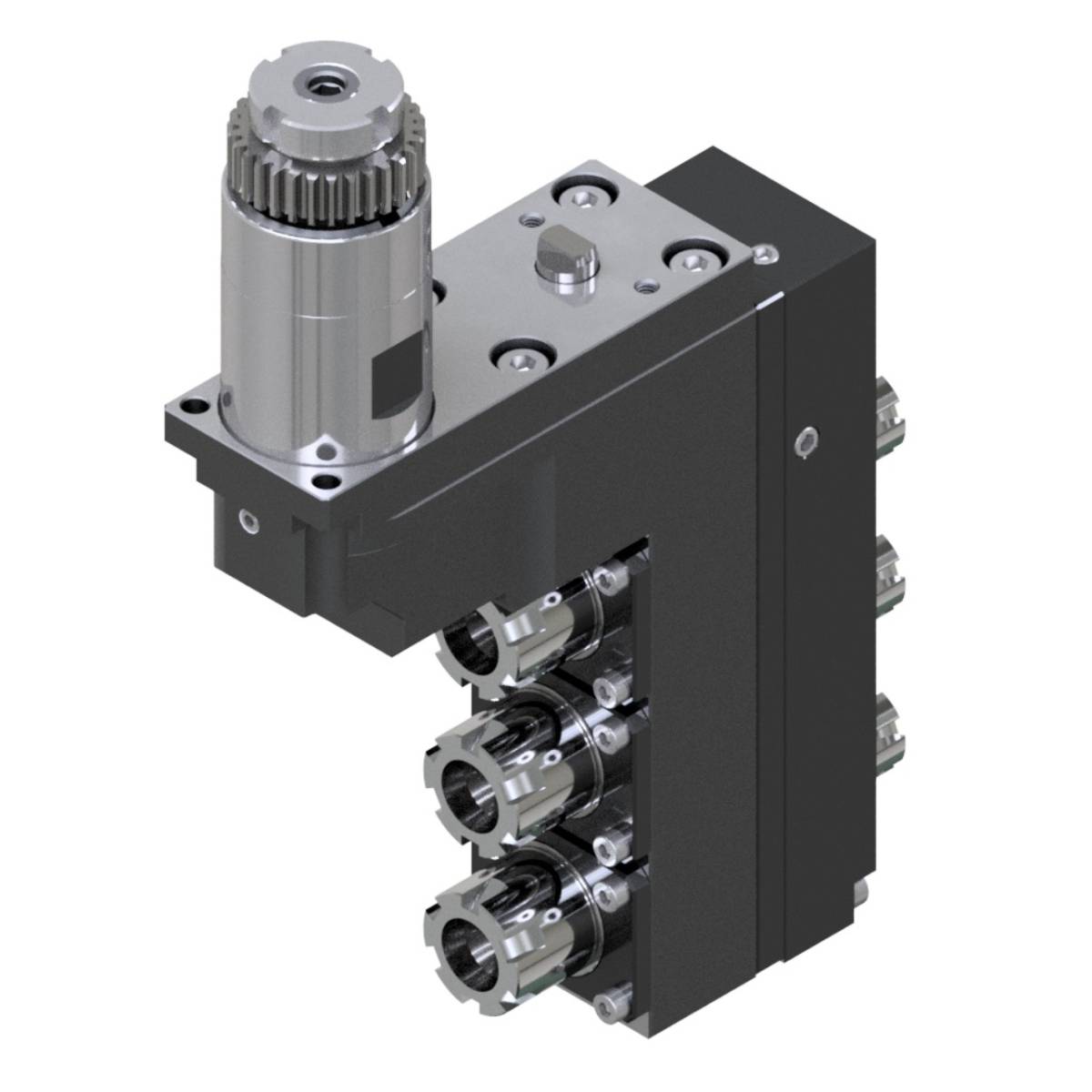

JARNG YEONG ENTERPRISE CO., LTD.

Product Description :

1. High rigidity body structure, machine base casting is integrally formed and high rigidity linear guide way, providing stabler, faster and higher precision.

2. Built-in main spindle is with C-axis function, high speed, big power, high precision and low vibration which can make surface of workpiece smoother.

3. Optional:Synchronous rotary guide bushing device, it's suitable for processing long workpiece which can reduce cycle processing time and improve production efficiency.

4. Sub-spindle is with C-axis function, it can work with live tooling for end side drilling, tapping and milling.

5. It can depend on different demand of machining to with or without Synchronous rotary guide bushing device.

6. Axes:Z1/X1/Y/C1/Z2/X2/C2 + 3 sets of live tooling devices (A/B1/B2)

7. Max. 23 tools, can do machining on front side and back side at the same time which can save time for processing.

8. With guide bush type travel is 180mm, min. offal is 150mm. Without guide bush type travel is 310mm, min. offal is 50mm.

FUTECH PRECISION CO.,LTD.

Product Description :

FUL series CNC Lathe is to enhance high speed and high accuracy. 45 degree slant bed construction features high rigidity and high stability.

X、Z axis are mounted with ball type linear guide ways or box guide ways. Axis movement is directly driven by a servo motor , allowing the high rapid traverse rates on X、Z axis.

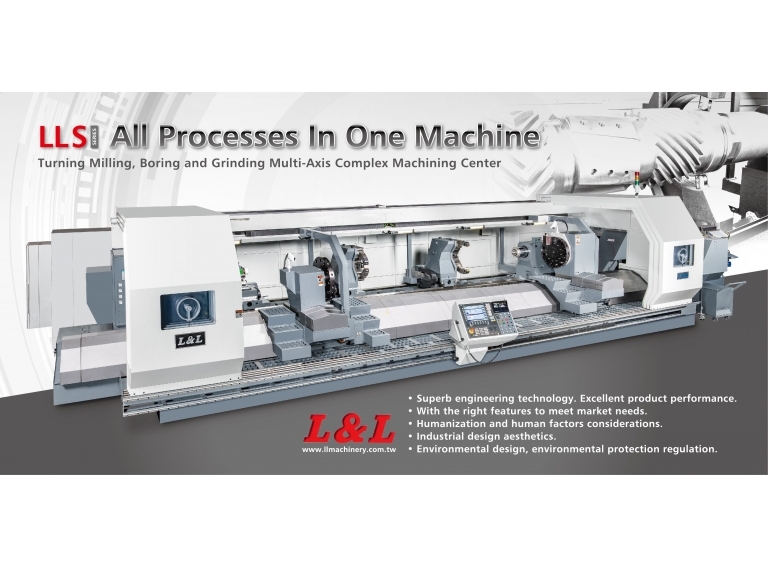

L & L MACHINERY INDUSTRY CO., LTD.

Product Description :

L&L LLS multi-axis composite cutting center machine, targeting the plastic rubber machinery industry, the application function exceeds customer demand:

a. Reduce the number of times of machining twice, reduce tool interference, and reduce work time by 50%.

b. Bed structure patent, one-piece casting, μ-level scraping process to ensure accuracy and stability.

c. Programmable tailstock, hydraulic center frame, independent chip removal device, programmable automatic door, high speed splash screen, full cover sheet metal design.

d. Full-cover design reduces the leakage of coolant, the design of the coolant collect plate for bed base, and the addition design of oil mist collector to reduce oil and gas pollution.

MING YANG MACHINERY CO., LTD.

Product Description :

Twin spindle configuration allows for both front and back machining.

Equipped with Sauter Turret

•C-axis functionality on both main and sub-spindle.

•Y-axis functionality promotes side and face milling, drilling, and tapping.

•12-station live turret ensures efficient milling, drilling, and tapping.

•A2-5 spindle nose.

6000rpm high speed spindle.

•High precision spindle accommodates collect chucks and 3-jaw chucks.

•X, Z, Y-axis feed rates: 24/24/10 M/min

LIS AUTOMATIC CONTROLLED CO., LTD.

Product Description :

PJ-20V0 is a surprising design. In addition to the dead corners of the bar feeder, there are also many spaces that easy to ignore, used by customers to pile up the stuff and lose the value of use. The idea of PJ-20V0 revitalizes these spaces and is no longer limited to 2D imagination, also to evolve to the concept of 3D space. This system provides a powerful and compliant function system for users continuously. Using for continuous variable volume (pressure), saving the electricity cost and the time of the adjusted pressure. Suitable for the Swiss Lathes and gun drilling.

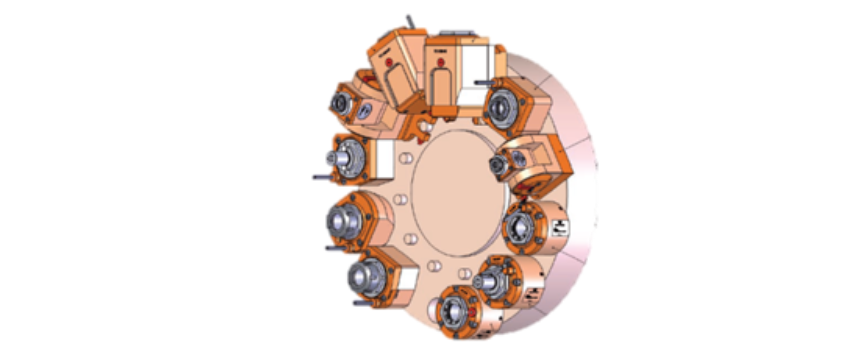

CHIAH CHYUN MACHINERY CO., LTD.

Product Description :

■No matter what operation – turning, milling, drilling, tapping, cutting, side turning and back machining, the

CB series does it all in one operation.

■Sliding head without a guide bush design provide faster setups, lesser remnants, and more cost reduction.

■The CB series provide multiple tooling systems is suitable for versatile cutting applications. On the front side

tooling system, user can set with 4+3 live tools, 6 O.D. tools and 5 I.D. tools. Moreover, on the back milling

system, user can set 4 live tools. The maximum tool speed is 6000 rpm. User can install O.D. and I.D. tools

on the back milling system.

■The sub-spindle head moves on the precision roller type linear ways with extra-large span design for

outstanding stability and positioning accuracy.

LEADWELL CNC MACHINES MFG., CORP.

Product Description :

Twin spindle & twin turret design, it can turn the different parts on the spindle and identical parts on both spindles at the same time. Integrated with 3-axis robot arms, to reach different OP and automation requested. Considering the turning efficiency, with automation high-speed robot reduces the loading/unloading time, with a high rigidity stricture design to increase the stability. On the other hand, the multiple types of robot arms will be able to satisfy the different demands of the client.

Max. swing: 290mm

Max. turning diameter: 290mm

Max. turning length: 220mm

X-axis travel: 195+5mm

Z-axis travel: 300mm

Spindle speed: 3500rpm

Spindle nose: A2-6

Chuck size: 10"

Spindle motor power: 11/15kw

Number of tool stations: 12T