Theme

Digital Transformation

Green Transformation

LEADWELL CNC MACHINES MFG., CORP.

Product Description :

The multi-function machine with B-axis can easy have bevel angle drilling and cutting work. The best torque is 3000Nm, and with curved coupling, it can easily do a heavy cutting job shop work and also curved surface milling. The machine uses special Electro Spindle, which can reach 12000rpm, it is a special machine can do a first mill and end mill in the same machine. The Y-axis design is a perpendicular type, and match with our moving column machine structure, the Y-axis have complete movement. It will not have dead space for the travel. (Y-axis travel /-130mm).

Max. swing: 750 mm

Max. turning diameter: 670 mm

Max. turning length: 1700 mm

Bar capacity: 78 mm

X-axis travel: 600+50 mm

Y-axis travel: ±130 mm

Z1-axis travel: 1750 mm

Z2-axis travel: 1725 mm

B-axis angular stroke: 240°(-30°~+210°) mm

Spindle speed(chuck): 3500 rpm

Spindle nose(chuck): A2-8/10"

Spindle speed(electro): 12000 rpm

X/Y/Z1/Z2-axis rapid traverse: 30/24/30/30 m/min

Tool storage capacity: 40 T

CHIAH CHYUN MACHINERY CO., LTD.

Product Description :

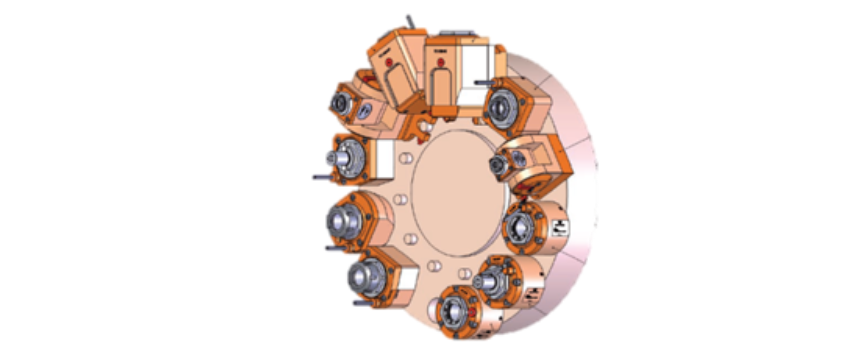

■No matter what operation – turning, milling, drilling, tapping, cutting, side turning and back machining, the

CB series does it all in one operation.

■Sliding head without a guide bush design provide faster setups, lesser remnants, and more cost reduction.

■The CB series provide multiple tooling systems is suitable for versatile cutting applications. On the front side

tooling system, user can set with 4+3 live tools, 6 O.D. tools and 5 I.D. tools. Moreover, on the back milling

system, user can set 4 live tools. The maximum tool speed is 6000 rpm. User can install O.D. and I.D. tools

on the back milling system.

■The sub-spindle head moves on the precision roller type linear ways with extra-large span design for

outstanding stability and positioning accuracy.

WIN HO TECHNOLOGY INDUSTRIAL CO., LTD.

Product Description :

主軸箱 <br />

全部齒輪及槽軸都用合金鋼製成<br />

經滲碳處理及精密研磨。 <br />

旋轉式變速機構操作簡單。<br />

<br />

齒輪箱 <br />

全能車製螺紋機構,任意車製。 <br />

公制螺紋、英制螺紋、模數螺紋、<br />

徑節螺紋,不需變換齒輪。<br />

<br />

床身 <br />

高剛性之肋骨結構。 <br />

3V床軌設計,精度永保如新。 <br />

高精度寬大床面、經淬火並研磨。 <br />

一體成型落地底座適合重型工件並延長使用年限。<br />

<br />

兩頂心距離 <br />

全系列兩頂心多300mm可實際車<br />

削更長工件。<br />

<br />

尾座 <br />

軸承支撐,移動輕便。<br />

<br />

護床 <br />

滑座與床鞍加長加寬,重切削更強。 <br />

調整容易的超負荷安全裝置。<br />

SPINDLE 配有潤滑油手動和自動雙重潤滑給油系統。 <br />

<br />

主軸 <br />

超大直徑主軸,主軸孔徑153mm,230mm(OPT)。 <br />

超精密軸承三點支持式。<br />

<br />

快送及自動跳脫 <br />

自動縱向可任意控制跳脫距離,有縱向及橫向<br />

快送選擇。<br />

SONG GIA INDUSTRIAL CO., LTD.

Product Description :

●精密鉸孔神器-浮動鉸刀柄,可解決以下問題:

1. 孔的直線行差

2. 鉸刀不耐用

3. 孔的尺寸擴大,尺寸精度達不到要求

4. 孔的中間大,兩頭小,圓柱度達不到要求

5. 內孔表面粗糙度達不到要求

6. 大批生產時無法保證孔徑尺寸的一致性 。

●浮動鉸刀柄的特點:

1.可透過360度浮動讓鉸刀對準下孔徑,避免對不準而造成擴孔或縮孔

2.徑向振幅抑制在5μm以下

3.提高鉸孔光潔度

4.彌補車床公差,提高鉸孔精密度

5.提高鉸孔的直線度和圓柱度

●浮動鉸刀柄可應用加工機械:鑽床、立式加工中心、研磨機。 可夾持工具:鉸刀、滾光刀

**產品連結→→https://www.songgia.com.tw/tw/products/other-tools/floating-reamer-holder

WELE MECHATRONIC CO., LTD.

Product Description :

1.立車主軸轉盤以進口交叉滾子軸承設計,確保重負荷的能力及長期的精度壽命。

2. Z軸226 mm方型滑枕搪孔軸採硬軌配Turcite B結構,VTC1612-CW標準行程900mm。

3.底座、立柱、橫樑、工作台等大型鑄件依製造需要,經由最新的3D設計,剛性最佳化,並以

多年經驗訂定有效的退火程序以消除殘餘應力,多年實際應用經驗,確實能達成有效的長期精

度保持性。

4.X、Z軸標準配備採用「雙編碼器」的「雙」半閉環回饋系統,經濟有效的提高各軸的定位精度。

(X、Z軸可選購德國Heidenhain或西班牙FAGOR光學尺)。

5.VTC-CW標準刀庫容量為16P(16儲位),車刀型式及分配數目可依客戶要求處理。

6.主軸箱等關鍵零件係利用自有的「大型臥式鏜孔機」及「大型高精度三次元量測儀(三座標量床)」

確實達成應有的加工精度,確保優良的組裝基礎。

7.承襲歐美先進工具機廠的標準,以嚴格維護的「1.2米x1.2米」高精密度的方形標準平板做為精密

精度的基礎,對各項關鍵零件進行精密鏟花(刮研),使機器的各處結合面和滑動面均能達到正確的

幾何精度,確保機器應有的精度和壽命。

8.搭配高規格的Fanuc數控系統,標準功能包含:15吋彩色液晶螢幕、Fanuc全鍵式操作面板、

2MB記憶容量、Ethernet網路接口、Flash記憶卡插口、剛性攻牙及各種特殊補間(插補)等多項

高規格功能,能經濟有效的滿足各種使用需求。

9.採用的各項配套零組件均經過長期使用驗證,可確保機器長期運行的可靠性。

10.完整的品檢測試流程,搭配先進的自動光學直準儀、雷射干涉儀、球桿檢測儀、線上動平衡儀等

精密檢測儀器,確保出廠的機器都能達到設計的性能和應有的功能。

11.經驗豐富的研發團隊,突破老舊的包袱,協助客戶達成各種特殊需求。

12.兼具經驗和熱誠的服務團隊和完整的服務體系,可以及時有效的讓用戶的機器長保最佳使用狀態。

KCW ETERNAL ENTERPRISE CO., LTD.

Product Description :

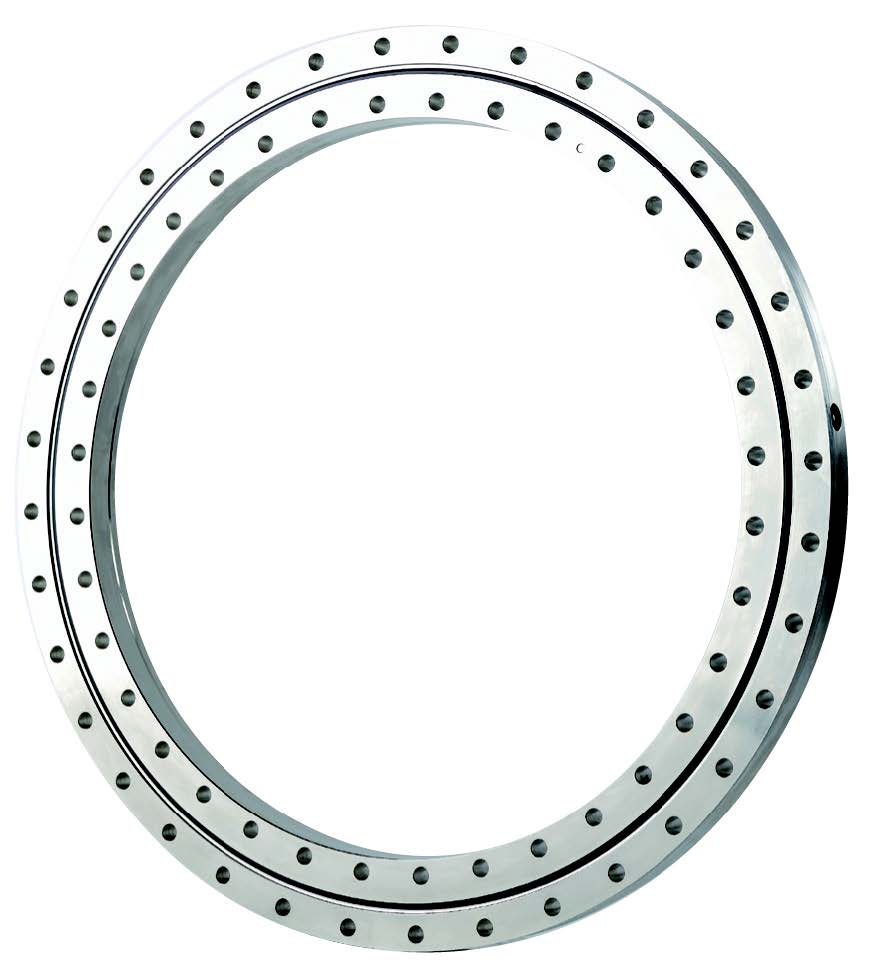

The Rollix precision slewing ring series is specially designed to meet the precision needs of customers.

High precision, high rigidity, low torque and smooth rotation

The simple design combines the functions of high load-bearing, rotation and locking holes.

Mass-produced pre-load structure with highly stable precision and quality

Convenient and fast design and installation, reducing matching components

We have planned inventories at Taiwan and abroad factory to speed up the development of prototypes.

TONGTAI MACHINE & TOOL CO., LTD.

Product Description :

‧Dual-spindle, dual-turret CNC lathe with an integrated loading/unloading robotic arm.

‧Designed for processes that require automatic single-piece feeding.

‧The MT series features a smaller footprint, shorter automation pathways, and higher productivity.

‧Short travel distances, minimal idle time, and minimal thermal displacement.

‧The TiOperator enables the MT series to achieve efficient 24-hour operation effortlessly.