Theme

Digital Transformation

Green Transformation

CHIN MING PRECISION TOOLS CO., LTD.

Product Description :

★ Single Crystal Diamond(Ultra Precision Cutting):

【CVD- HV8,000 ~ 10,000】

【MCD- HV5,000 ~ 10,000】

Work Material:Ceramic, Gold / Silver / Aluminum / Copper / Zinc / Magnesium Alloy, Titanium Alloy, Graphite, Carbon Fiber / Glass Fiber, Wood, Bakelite, Acrylic, Stone, Electroless Nickel, Carbide.

★ Polycrystalline Compound Diamond【HV6,500 ~ 8,000】:

Work Material:Ceramic, Aluminum / Copper, Titanium Alloy, Graphite, Carbon Fiber / Glass Fiber, Wood, Bakelite, Acrylic, Stone, Carbide.

★ Polycrystalline Cubic Boron Nitride【HV3,000 ~ 5,000】:

Work Material:Hardened Steel(HRC45~65°), Powder Metallurgy.

BEST DIAMOND INDUSTRIAL CO., LTD.

Product Description :

Compared to resin bond and metal bond wheels, Electroplated Grinding Tools are noted for relatively large grit protrusion and higher abrasive concentration. This results in very free cutting properties and in high stock removal capacity. Besides, these tools are noted for:

1. Allow special shapes and profile tools to be made at short notice.

2. Cause very little change on wheel shape after used, suitable for precision grinding.

Application and Processing Material for Electroplated Grinding Tools :

1. Internal grinding: Suitable for the internal grinding of carbide and High Speed Steel. The smallest diameter of our electroplating area is 0.3mm so it could be used in drilling for fined ceramics.

2. Jig grinding: Mostly used in fined ceramics processing and precision grinding for quartz. Customized items are also provided to cater your needs. Common grit size is #80~#325, good for rough and fine processing.

3. Touchscreen Processing: Drilling and chamfering for the glass panel of the smart phone and tablet computer. In order to improve work efficiency, we could also combine different grit sizes in the same diamond mounted point.

4. Grinding for Cutting tools: Normal end-mill grinder and drill grinder go with electroplated wheel. Carbide can be ground by diamond wheel and High Speed Steel could be ground by CBN wheel. Bowl-shape wheel with standard specification is also provided, suitable for the grinding of turning tools.

5. Precision grinding: Electroplating can produce wheel of different shapes without deforming it. Therefore, it is suitable for precision grinding or trimming aluminum oxide wheel.

6. Gem grinding: shape grinding for gem, semi-precious stones, shell and jade.

KENTURN NANO. TEC. CO., LTD.

Product Description :

Our own manufacturing spindle can fulfill the coolant of axis also inhibit the heat and thermal deformation by using the Germany original OTT HSK-A63 drawbar system. Besides, the oil-air lubricating bearings can stand long-term cutting operation. The spindle, motor power is up to 25KW, speed 18000 RPM, using dualdrive chunk, can be used in vertical machining centers and medium gantry machine.

VISION WIDE TECH CO., LTD.

Product Description :

One of the proudest products of Vision Wide which fulfills automatic 5-face machining with super rigidity structure and high positioning accuracy. HF satisfies demands in mold surface cutting, angle cutting, 3D mold cutting, and precise contour finishing.

TAIHO TOOL MFG. CO., LTD.

Product Description :

AE-VM features good stiffness, unequal lead and helix angle to enhance anti-vibration.

New flute design fulfills better chip removing.

New Coating “DUARISE” provides advantage on lubricity, wearability, high temperature oxidation resistance, and muti-layer structure can prevent it from thermal cracking.

Standard Type and Short Blade Type(AE-VMS、AE-VMSS):Square, Radius, and 90°(-RA) end mill.

3D, 4D Long Blade Type(AE-VML):Square, Radius, and Chip-breaking flute(AE-VML-N) end mill.

Side Milling Type(AE-VMFE): Square, and Radius end mill.

NINE-9 CUTTING TOOLS CO., LTD.

Product Description :

NC Helix Drill cuts material by helical interpolation; serrated cutting edge minimizes chip length.

Low spindle power is not a problem, good for drilling material that generates long, soft chips.

● Reduce Your Tool Inventory

Each holder can machine di erent diameters and hole depths, saving your tool inventory and cost!

No need to peck drill or dwell in operation even machine without internal coolant.

● Lower spindle power consumption Easy to cut!

• Thanks to the small cutting load of the serrated cutting edge and helical interpolation lower power consumption. Work quicker, smarter and achieve better results.

• Circular ramping milling, maximum ramping angle is 20°. For example: tool HD27 machining Ø50 mm hole, 9 mm pitch for aluminum, 6 mm pitch for carbon steel.

● Special insert geometry - exceptional swarfs control.

• Serrated cutting edge makes the chips short and small, and easier to evacuate.

• Eliminate swarf and vibration problems while drilling di cult material or deeper holes.

● “One tool” performs multiple applications

• Not only a drill, but an end mill too.

• Small radius path to cut a hole or step hole, various curved cavity shapes on di erent materials.

SHARPMAX TOOL INC.

Product Description :

● Engineered with eccentric relief for maximum edge strength in both roughing and finishing applications.

● Variable pitch geometry results in higher quality parts by decreasing chatter and harmonics.

● ZrN coating offers high hardness for estended tool life in high temp alloys and ferrous metals including stainless stee.

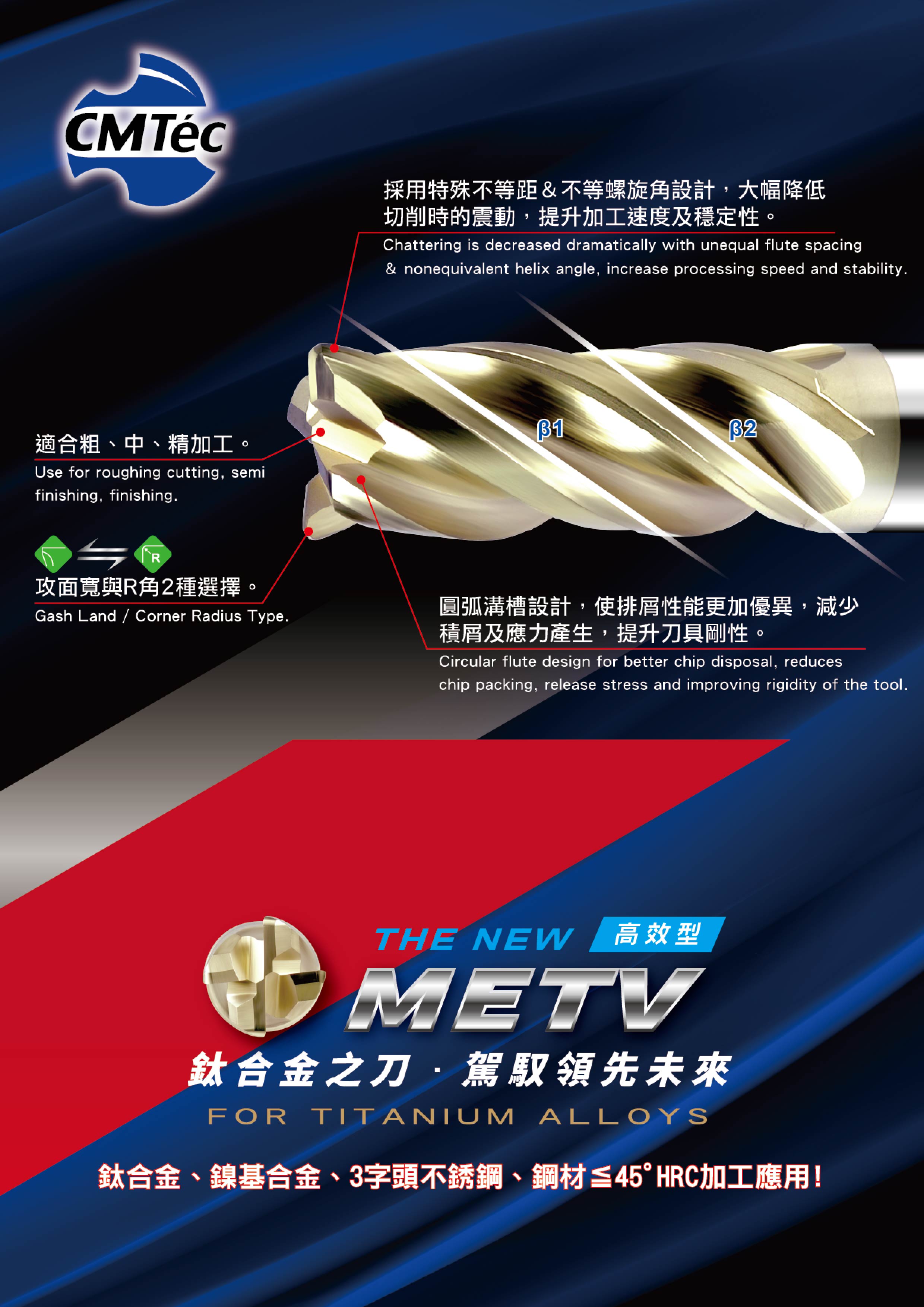

CHIN MING PRECISION TOOLS CO., LTD.

Product Description :

★ For titanium alloy, stainless steel and alloy steel(≦45°HRC) machining.

★ Chattering is decreased dramatically with unequal flute spacing & nonequivalent helix angle, increase processing speed and stability.

★ Circular flute design for better chip disposal, reduces chip packing, release stress and improving rigidity of the tool.

★ Use for roughing cutting, semi finishing, finishing.

HON JAN CUTTING TOOLS CO., LTD.

Product Description :

Heat-treated steel

Coolant design

Perfect 90° milling

High number of teeth, increased productivity

PTN10-cutting depth up to 5mm

PTN16-cutting depth up to 10mm

PTN16-the clamping screw is enlarged for easier locking and greatly improved stability

The unique design of low cutting resistance can better machining continuity, achieve milling of 90°, and get a perfect machining surface.