Theme

Digital Transformation

Green Transformation

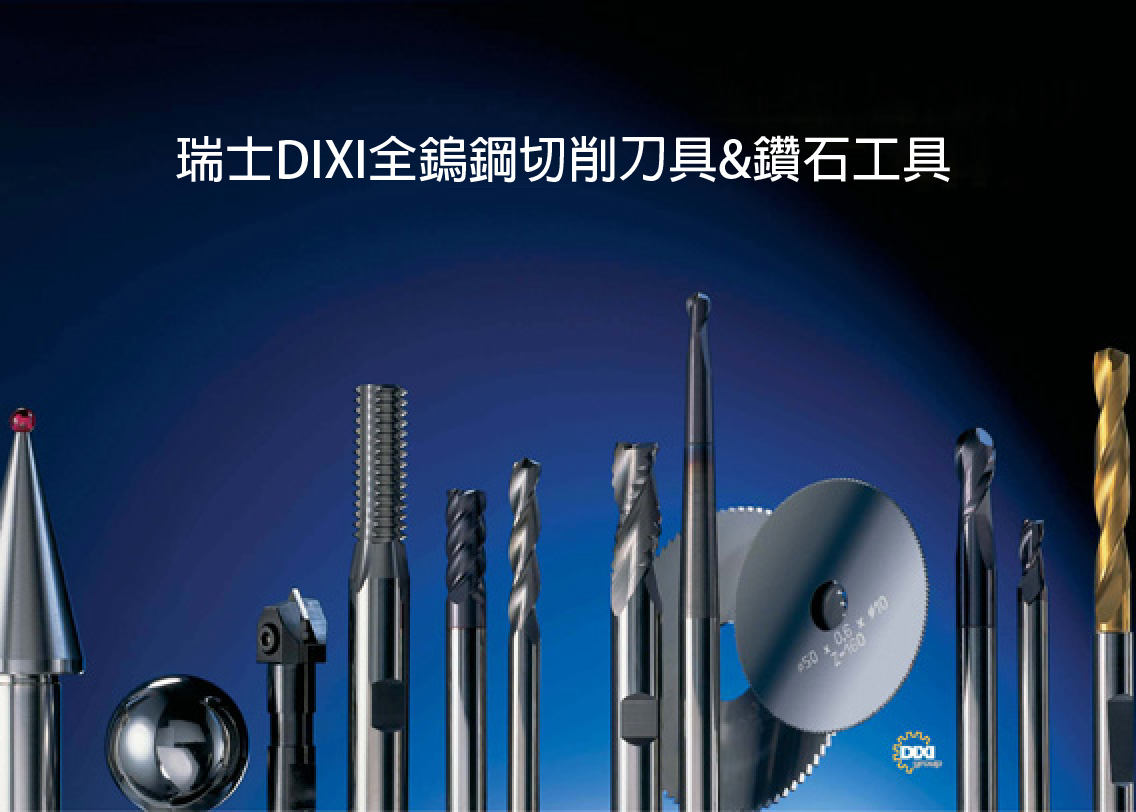

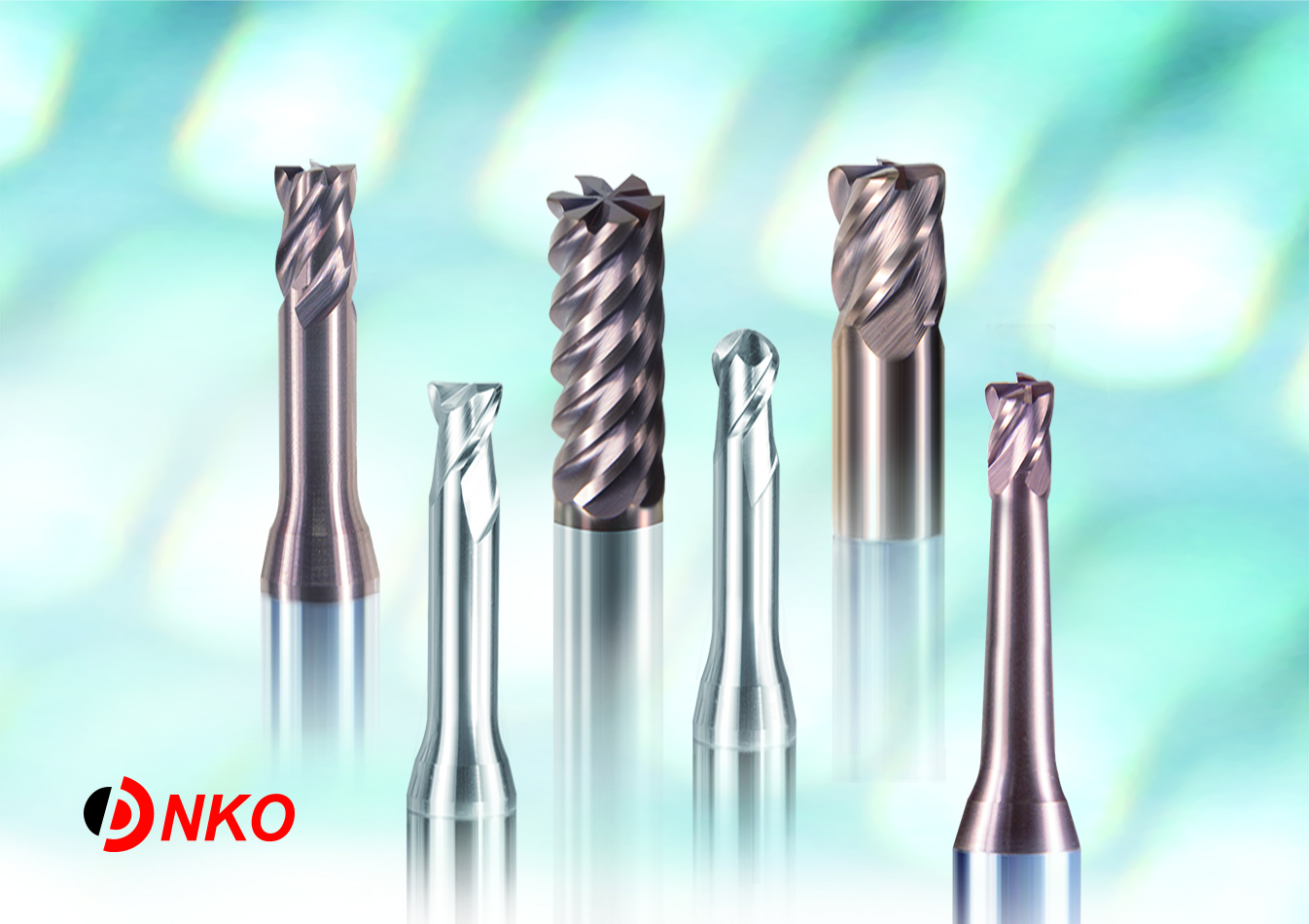

JIN LI CHENG CUTTING TOOL CO., LTD.

Product Description :

※ We design and manufacture "speci c industry" tools

with fast delivery and great quality.

※ It can be designed according to the highest standard

and speci cation from customers. Flexible manufacturing

and accept customized tolerance.

※ From concept to nal completion. JLC customized

tools will reduce the cutter exchange labor time and

improve the e

ciency of mass production.

JIN LI CHENG CUTTING TOOL CO., LTD.

Product Description :

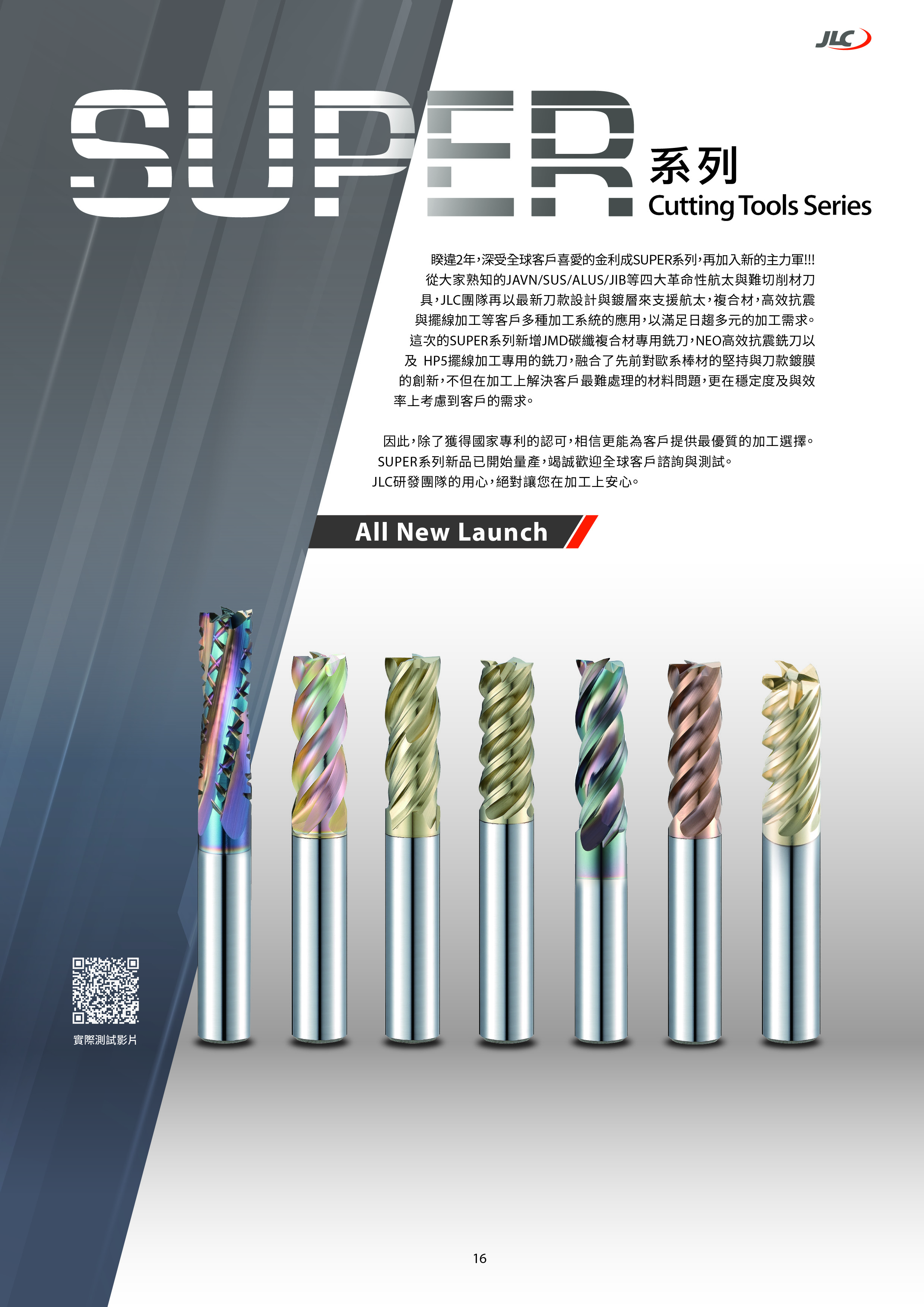

睽違2年,深受全球客戶喜愛的金利成SUPER系列,再加入新的主力軍!!!

從大家熟知的JAVN/SUS/ALUS/JIB等四大革命性航太與難切削材刀具,JLC團隊再以最新刀款設計與鍍層來支援航太,複合材,高效抗震與擺線加工等客戶多種加工系統的應用,以滿足日趨多元的加工需求。

這次的SUPER系列新增JMD碳纖複合材專用銑刀,NEO高效抗震銑刀以及 HP5擺線加工專用的銑刀,融合了先前對歐系棒材的堅持與刀款鍍膜的創新,不但在加工上解決客戶最難處理的材料問題,更在穩定度及與效率上考慮到客戶的需求。因此,除了獲得國家專利的認可,相信更能為客戶提供最優質的加工選擇。

SUPER系列新品已開始量產,竭誠歡迎全球客戶諮詢與測試。

JLC研發團隊的用心,絕對讓您在加工上安心。

JIN LI CHENG CUTTING TOOL CO., LTD.

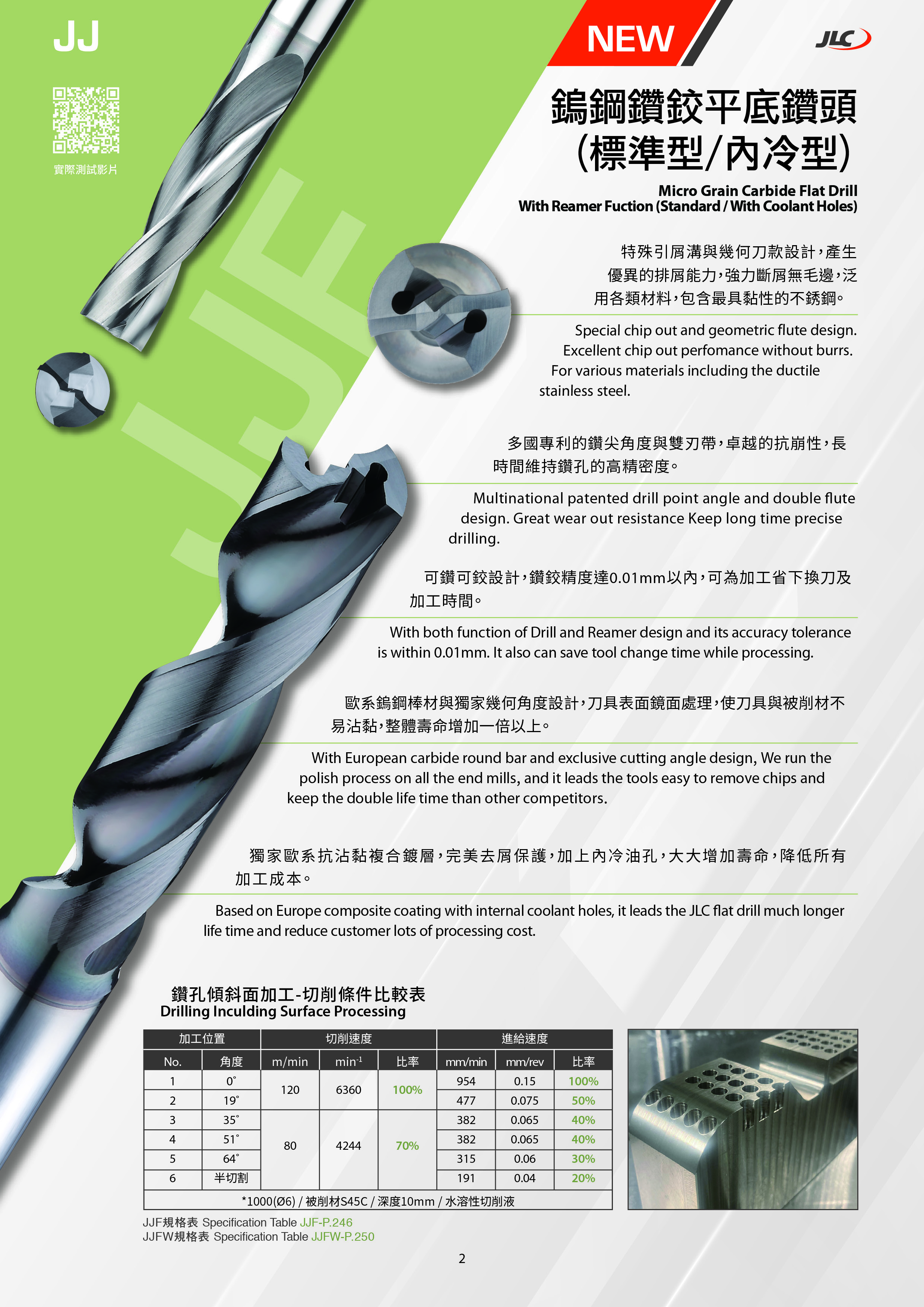

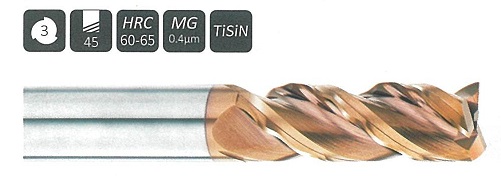

Product Description :

※Special chip out and geometric flute design. Excellent chip out perfomance without burrs. For various materials including the ductile stainless steel.

※Multinational patented drill point angle and double ute design. Great wear out resistance Keep long time precise drilling.

※With both function of Drill and Reamer design and its accuracy tolerance is within 0.01mm. It also can save tool change time while processing.

※With European carbide round bar and exclusive cutting angle design, We run the polish process on all the end mills, and it leads the tools easy to remove chips and keep the double life time than other competitors.

※Based on Europe composite coating with internal coolant holes, it leads the JLC at drill much longer life time and reduce customer lots of processing cost.

SHARPMAX TOOL INC.

Product Description :

● Designed for high performance rough machining of

Titanium and other exotic materials.

● Optimum performance with maximum chip load per

tooth and efficient chip formation with higher

volume of metal removal.

● Exclusive PVD coating for long life.

● Vibration Free.

NINE-9 CUTTING TOOLS CO., LTD.

Product Description :

The “ i-Center ” is a trademark of Nine9,

the developer of the first indexable center drill in the world.(Patented)

Offering an indexable insert system for the 1st time, Nine9’s “i-Center ” design improves your process performance. Shortens set up and center drilling time.Increases tool life and reduces tooling costs.

● High Speed, High Feed Rate

• The special ground insert and rigid holder design facilitate high performance speed and feed rates. For example, drilling alloy steel

at 6000 rpm and feed rate of 600 mm/min. (0.1 mm/rev.).

● Excellent Repeatability

• The positioning repeatability of the insert is within 0.02 mm

(.0008”) in radial direction, thus ensuring conformity to any national

standards.

● Easy Tool Length Setting

• The axial position accuracy of the insert is 0.05 mm (.002”). It is

not necessary to reset the tool length when changing or cutting edge.

● Extended Tool Life

• Coolant can be supplied through the center of the holder to increase performance and extend tool life.

• Insert geometry, grades and coating process are specifically engineered for centering applications.

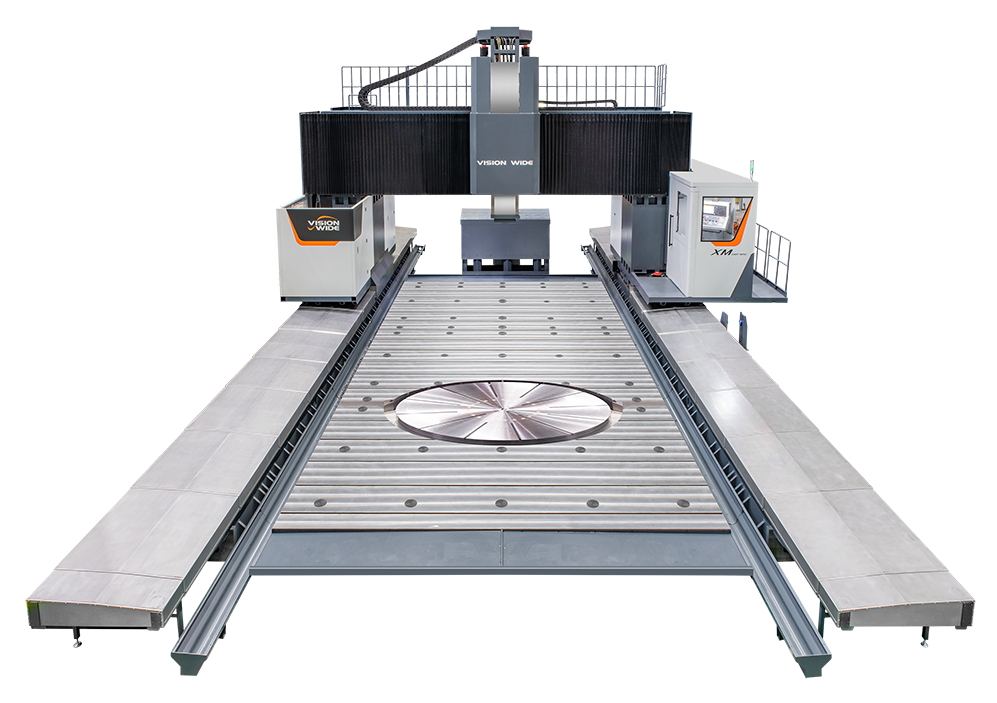

VISION WIDE TECH CO., LTD.

Product Description :

High Performance and Wide Application

XM series moving column machining center is a product developed for the machining needs of large-scale precision machinery, electric power, wind power, energy, petrochemical, transportation... and other equipment. It has:

Huge workpiece machining space: For precision machining of various types of structural parts, it can provide super large XYZ axis machining space.

• High-precise positioning: The high-standard geometric accuracy and positioning accuracy capabilities of the whole machine enable large-scale precision machining

• Heavy cutting capacity: Provide a variety of high-rated torque spindles to meet the processing and cutting capabilities of various materials.

• Fully automatic multi-face machining: This moving column machining center can be matched with various automatic attachment heads for high tangential speed mold surface machining and various types of precision parts complex angle machining, with excellent tool tip point error automatic correction function, and automatic additional head and tool exchange function, it can realize fully automatic machining performance.

• Milling and turning compound multitask: This moving column cnc milling machine can be equipped with a high-torque and high-speed vertical turning table to realize milling and turning compound automatic machining.

NINE-9 CUTTING TOOLS CO., LTD.

Product Description :

NC Helix Drill cuts material by helical interpolation; serrated cutting edge minimizes chip length.

Low spindle power is not a problem, good for drilling material that generates long, soft chips.

● Reduce Your Tool Inventory

Each holder can machine di erent diameters and hole depths, saving your tool inventory and cost!

No need to peck drill or dwell in operation even machine without internal coolant.

● Lower spindle power consumption Easy to cut!

• Thanks to the small cutting load of the serrated cutting edge and helical interpolation lower power consumption. Work quicker, smarter and achieve better results.

• Circular ramping milling, maximum ramping angle is 20°. For example: tool HD27 machining Ø50 mm hole, 9 mm pitch for aluminum, 6 mm pitch for carbon steel.

● Special insert geometry - exceptional swarfs control.

• Serrated cutting edge makes the chips short and small, and easier to evacuate.

• Eliminate swarf and vibration problems while drilling di cult material or deeper holes.

● “One tool” performs multiple applications

• Not only a drill, but an end mill too.

• Small radius path to cut a hole or step hole, various curved cavity shapes on di erent materials.