Theme

Digital Transformation

Green Transformation

BEST DIAMOND INDUSTRIAL CO., LTD.

Product Description :

Compared to resin bond and metal bond wheels, Electroplated Grinding Tools are noted for relatively large grit protrusion and higher abrasive concentration. This results in very free cutting properties and in high stock removal capacity. Besides, these tools are noted for:

1. Allow special shapes and profile tools to be made at short notice.

2. Cause very little change on wheel shape after used, suitable for precision grinding.

Application and Processing Material for Electroplated Grinding Tools :

1. Internal grinding: Suitable for the internal grinding of carbide and High Speed Steel. The smallest diameter of our electroplating area is 0.3mm so it could be used in drilling for fined ceramics.

2. Jig grinding: Mostly used in fined ceramics processing and precision grinding for quartz. Customized items are also provided to cater your needs. Common grit size is #80~#325, good for rough and fine processing.

3. Touchscreen Processing: Drilling and chamfering for the glass panel of the smart phone and tablet computer. In order to improve work efficiency, we could also combine different grit sizes in the same diamond mounted point.

4. Grinding for Cutting tools: Normal end-mill grinder and drill grinder go with electroplated wheel. Carbide can be ground by diamond wheel and High Speed Steel could be ground by CBN wheel. Bowl-shape wheel with standard specification is also provided, suitable for the grinding of turning tools.

5. Precision grinding: Electroplating can produce wheel of different shapes without deforming it. Therefore, it is suitable for precision grinding or trimming aluminum oxide wheel.

6. Gem grinding: shape grinding for gem, semi-precious stones, shell and jade.

NINE-9 CUTTING TOOLS CO., LTD.

Product Description :

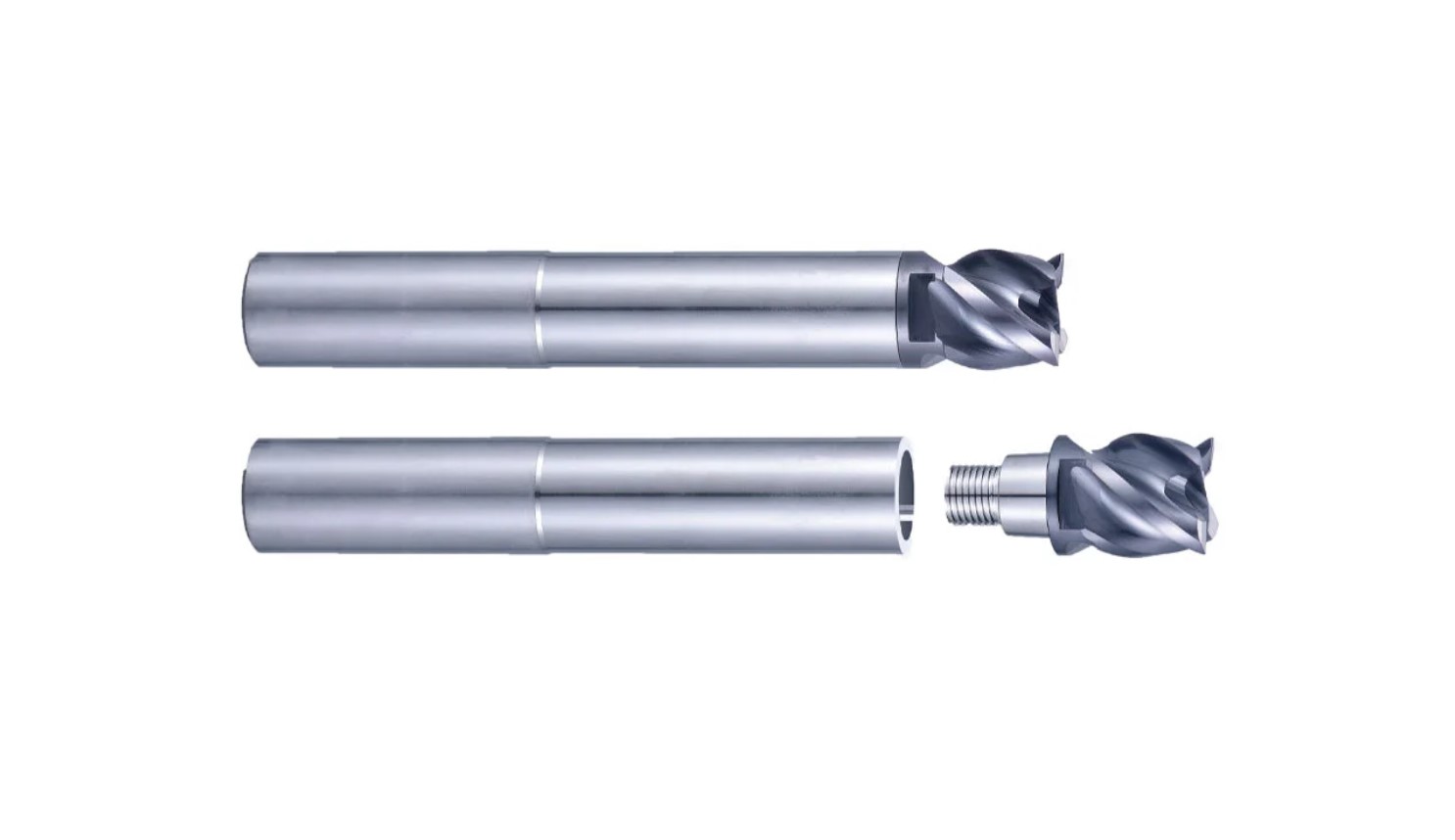

The “ i-Center ” is a trademark of Nine9,

the developer of the first indexable center drill in the world.(Patented)

Offering an indexable insert system for the 1st time, Nine9’s “i-Center ” design improves your process performance. Shortens set up and center drilling time.Increases tool life and reduces tooling costs.

● High Speed, High Feed Rate

• The special ground insert and rigid holder design facilitate high performance speed and feed rates. For example, drilling alloy steel

at 6000 rpm and feed rate of 600 mm/min. (0.1 mm/rev.).

● Excellent Repeatability

• The positioning repeatability of the insert is within 0.02 mm

(.0008”) in radial direction, thus ensuring conformity to any national

standards.

● Easy Tool Length Setting

• The axial position accuracy of the insert is 0.05 mm (.002”). It is

not necessary to reset the tool length when changing or cutting edge.

● Extended Tool Life

• Coolant can be supplied through the center of the holder to increase performance and extend tool life.

• Insert geometry, grades and coating process are specifically engineered for centering applications.

7-LEADERS CORP.

Product Description :

Multipurpose End Mills with Corner Radius- 4 Flutes

Using UMG carbide material enable to enhance lubrication and wear resistance.

Effectively decrease the vibration by various helix geometry and unequal flutes designs.

Big chip breaker is designed to reach high removal rate for various work materials.

Cutting edge with corner radius design and nano multilayer coating AlCrN are suitable for carbon steel, alloy steel and stainless steel with impurities and sticky materials.

Suitable for various kinds of work materials from the end of roughing to finishing.

TAIHO TOOL MFG. CO., LTD.

Product Description :

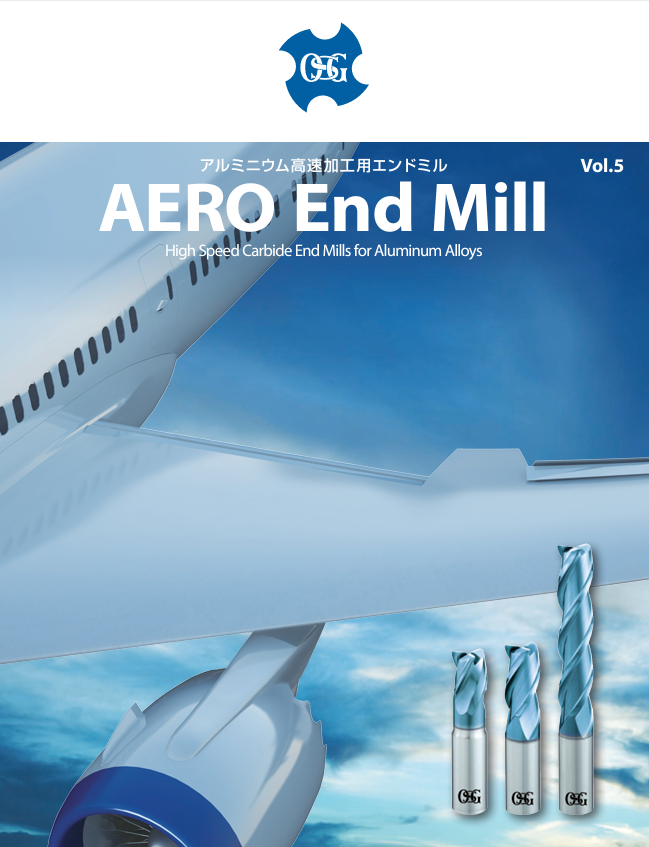

The AERO series is very suitable for high-power equipment above 80KW.

It has a sharp cutting edges and grooves for great efficiency of discharging the chips. The coating is OSG's diamond coating with glossy surface. This bright and smooth surface optimizes the performance of the end mill, especially in aluminum alloy that weldability and lubricity are required.

The 3-short-blade type and center jet type (AERO-ETS, AERO-O-ETS) are corner radius end mills applied to roughing and finishing.

The 3-long-blade type and extra long blade type (AERO-ETL, AERO-EXTL) are corner radius end mills applied to roughing and finishing.

The 2-short-blade type (DLC-AIR-EDS) is corner radius end mills applied to roughing and finishing.

7-LEADERS CORP.

Product Description :

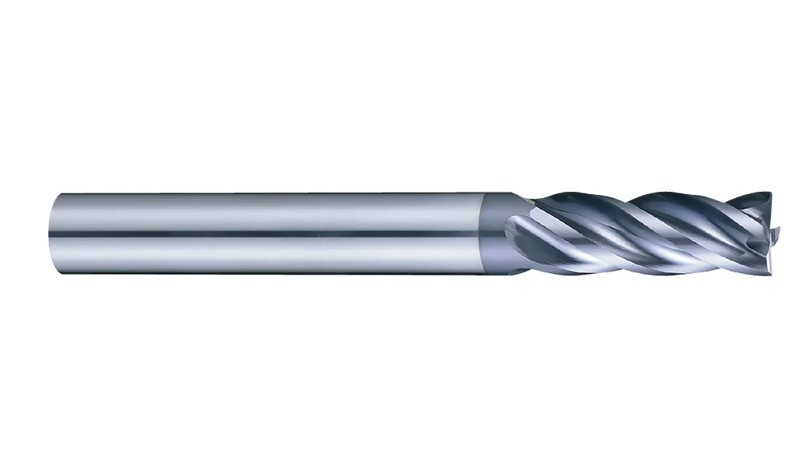

Multipurpose End Mills- 4 Flutes

Effectively decrease the vibration by various helix geometry and unequal flutes designs.

Big chip breaker is designed to reach high removal rate for various work materials.

Obviously improve tool life with Nano multilayer coating AlTiCrN.

Suitable for different kinds of materials cutting.

SHARPMAX TOOL INC.

Product Description :

● Periodic cutting stree is effectively suppressed by

continuously changing outer teeth spacing,allowing

for chattering control.

● Excellent anti-vibration performance compatible in a

wide variety of milling for exotic alloys including

SUS,inconel,and Titanium.

● Reduces chattering for high-speed and high-feed

cutting.

● Ultra-smooth coating with significantly

improvedcoating hardness and heat resistance

improves tool live in heat resisitive ally maching.