Theme

Digital Transformation

Green Transformation

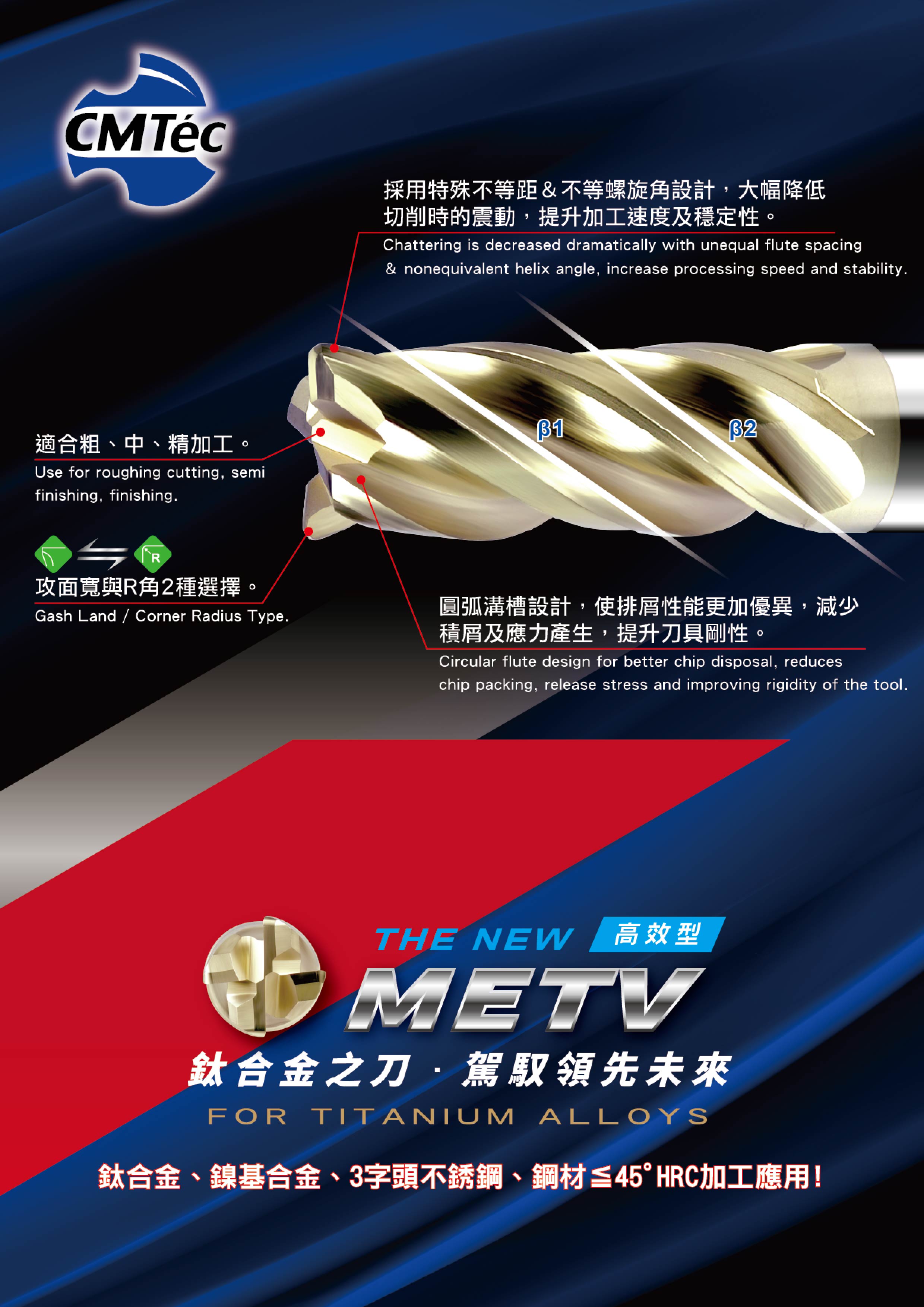

CHIN MING PRECISION TOOLS CO., LTD.

Product Description :

★ For titanium alloy, stainless steel and alloy steel(≦45°HRC) machining.

★ Chattering is decreased dramatically with unequal flute spacing & nonequivalent helix angle, increase processing speed and stability.

★ Circular flute design for better chip disposal, reduces chip packing, release stress and improving rigidity of the tool.

★ Use for roughing cutting, semi finishing, finishing.

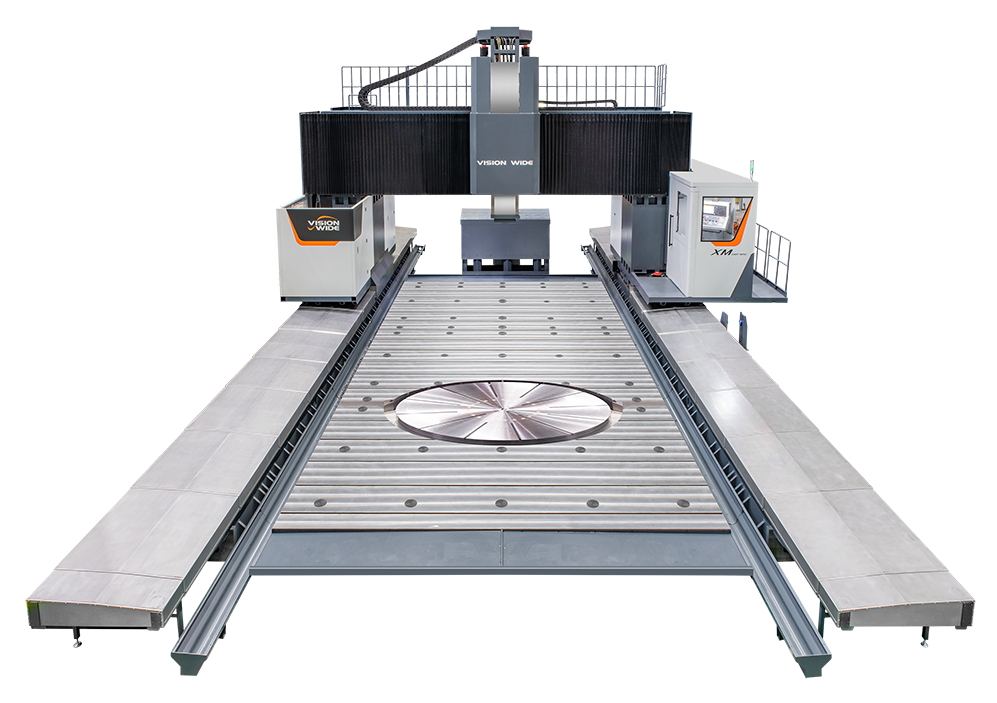

VISION WIDE TECH CO., LTD.

Product Description :

High Performance and Wide Application

XM series moving column machining center is a product developed for the machining needs of large-scale precision machinery, electric power, wind power, energy, petrochemical, transportation... and other equipment. It has:

Huge workpiece machining space: For precision machining of various types of structural parts, it can provide super large XYZ axis machining space.

• High-precise positioning: The high-standard geometric accuracy and positioning accuracy capabilities of the whole machine enable large-scale precision machining

• Heavy cutting capacity: Provide a variety of high-rated torque spindles to meet the processing and cutting capabilities of various materials.

• Fully automatic multi-face machining: This moving column machining center can be matched with various automatic attachment heads for high tangential speed mold surface machining and various types of precision parts complex angle machining, with excellent tool tip point error automatic correction function, and automatic additional head and tool exchange function, it can realize fully automatic machining performance.

• Milling and turning compound multitask: This moving column cnc milling machine can be equipped with a high-torque and high-speed vertical turning table to realize milling and turning compound automatic machining.

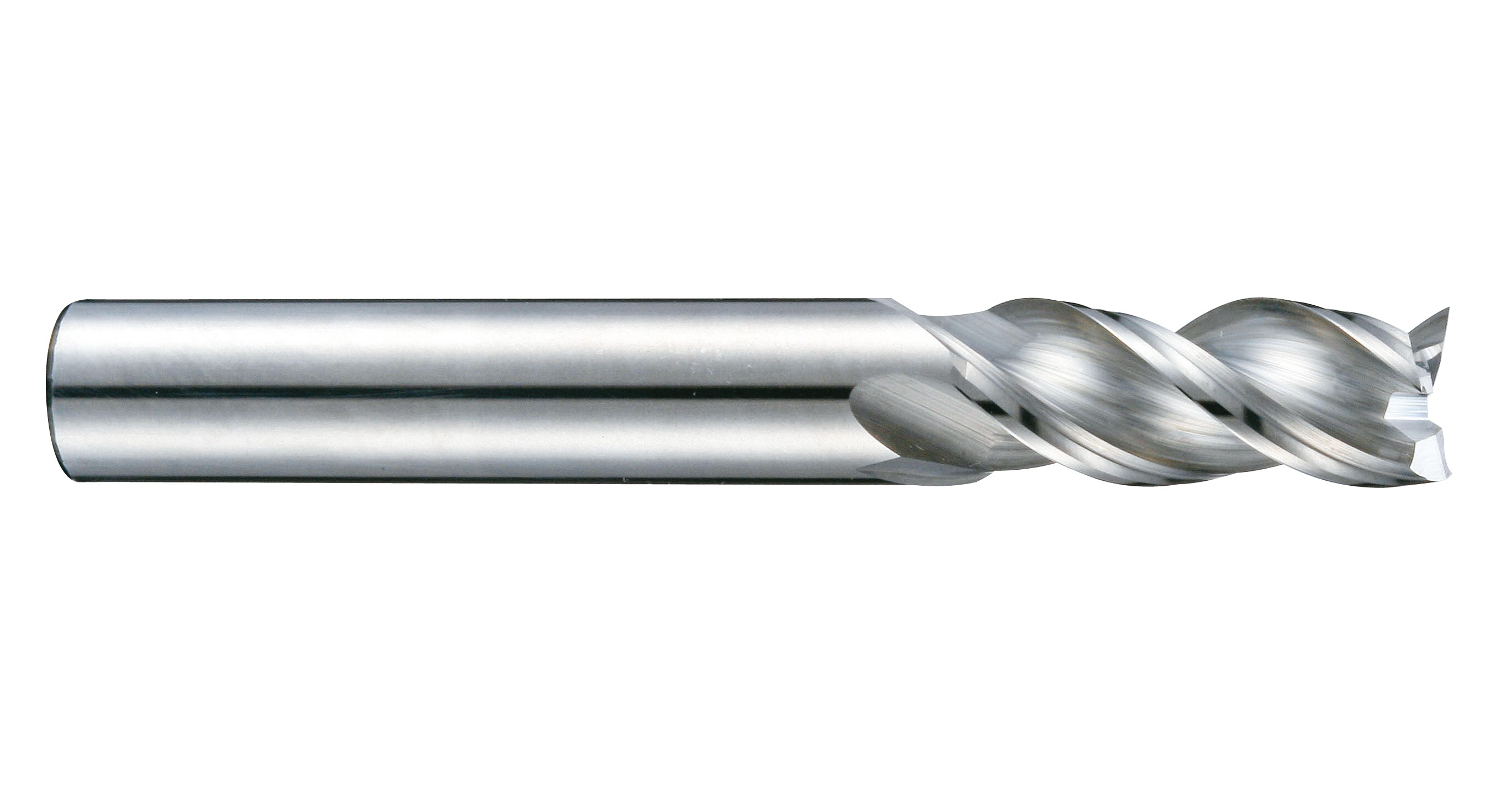

7-LEADERS CORP.

Product Description :

End Mills for Aluminium- 3 Flutes

Design with sharp cutting edge, high removal cutting geometry, and fine grinding smooth surface to prevent sticking problem.

Higher finishing of cutting edge to have better surface roughness after processing.

Application for roughing and finishing in various Aluminium.

MAROX TOOLS INDUSTRIAL CO., LTD.

Product Description :

【External Turning Tools with coolant】

AACLN、AATJN、AATQN、AAWLN、ADCLN、ADDJN、ADDQN、ADTEN、ADTJN、ADTQN、ADVJN、ADWLN、AMCLN、AMDJN、AMTJN、AMVJN、APCLN、ASCLC、ASDNC、ASDJC、ASTUP、ASVJB、ASVJC、ASVJP、ASVKB、ASVKC、ATJNR、AWLNR

【Boring Bar with coolant】

L-SCLC-V、L-SDUC-V、L-STLC-V、L-STUP-V

【Threading Tools with coolant】

ASER、ASER-WP、ASER-NA

【Grooving holder with coolant】

ACGWS、AEVSC/M、ADGT、AGHR、AGNDMR、AGHSR、AGWC、AKGD、ASLAL-38、ATGTR、ATSE、ATTE、AWGCSM、AUASR、AUSR

NINE-9 CUTTING TOOLS CO., LTD.

Product Description :

Nine9 chamfer mill is designed for chamfering and countersinking with an indexable insert.

The insert is a specifically designed for use in high speed machining ; the multiple flutes

provide for increased feed rate, optimizing performance and reducing cutting time.

High performance chamfer tool for upgrading your machining process.

For front and back chamfering. Eliminates 2nd operation or deburring time.

● Excellent Repeatability

• Smallest Indexable counter sink, diameter ø7 mm.

• The insert is dual-relief angle, specially edge honning and optimized coated for high cutting speed.

• Optimized the number of teeth on the holder to achieve higher feed rate.

● Economical

• Each insert has 4 cutting edges.

• Long tool life.

● Applications

• For front and back chamfering.

• 90° counter sink and 45° chamfering.

• For counter sink, circular chamfering, contour chamfering and face milling.

HON JAN CUTTING TOOLS CO., LTD.

Product Description :

●Internal and external threading for both left-thread and right-thread with one tooling

●Safe machining operation and easier to reach the bottom inside the blind holes

●Evacuate the chip more efficiently than the traditional milling process. shank: 20mm~40mm , Internal Thread Insert: 12I , 14I, 21I, 30I , 40I , External Thread Insert: 14E, 21E, 30E , 40E

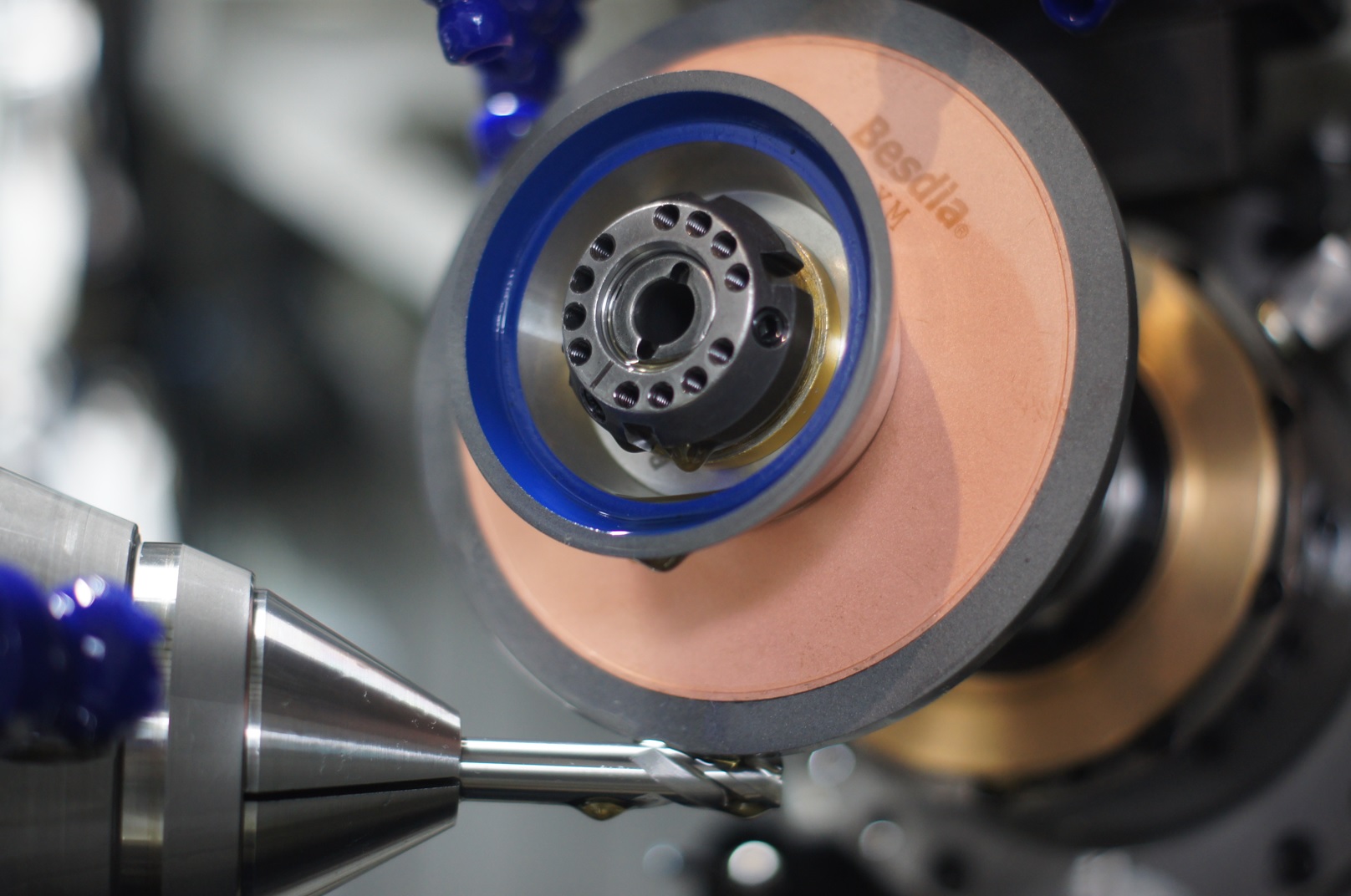

BEST DIAMOND INDUSTRIAL CO., LTD.

Product Description :

XM Hybrid Bond Grinding wheel (High Performance Fluting)

High metal bonding strength, good heat dissipation, good heat resistance and perfect shape retention make this material ideal for deep fluting, with high processing efficiency and stability. In terms of processing efficiency, product life, heat resistance, heat dissipation properties and wheel strength, it is comparable to imported grinding wheels from major brands. Its primary application is five-axis CNC tool grinding and slotting.

● Ultra efficiency : Exhibits exceptional cutting force. A single feed can reach over 3mm, improving processing efficiency significantly.

● Ultra durability : Fully utilizes the strength of the hybrid bonding method, exhibits good wheel shape retention and is suitable for long-term unattended processing.

● Ultra energy-saving : Displays the dual benefits of retaining cutting force and shape to reduce the spindle load, and eliminate the need for frequent grinding wheel sharpening, thereby conserving energy.

● Ultra cost-effectiveness : Consumables made in Taiwan with imported quality and extremely competitive pricing, reducing the company's costs for these items.

NINE-9 CUTTING TOOLS CO., LTD.

Product Description :

The “ i-Center ” is a trademark of Nine9,

the developer of the first indexable center drill in the world.(Patented)

Offering an indexable insert system for the 1st time, Nine9’s “i-Center ” design improves your process performance. Shortens set up and center drilling time.Increases tool life and reduces tooling costs.

● High Speed, High Feed Rate

• The special ground insert and rigid holder design facilitate high performance speed and feed rates. For example, drilling alloy steel

at 6000 rpm and feed rate of 600 mm/min. (0.1 mm/rev.).

● Excellent Repeatability

• The positioning repeatability of the insert is within 0.02 mm

(.0008”) in radial direction, thus ensuring conformity to any national

standards.

● Easy Tool Length Setting

• The axial position accuracy of the insert is 0.05 mm (.002”). It is

not necessary to reset the tool length when changing or cutting edge.

● Extended Tool Life

• Coolant can be supplied through the center of the holder to increase performance and extend tool life.

• Insert geometry, grades and coating process are specifically engineered for centering applications.