Theme

Digital Transformation

Green Transformation

VISION WIDE TECH CO., LTD.

Product Description :

GSF Series 5-axis Gantry Type Machining Center, provided excellent 5-axis simultaneous accuracy performance for 5-axis machining in mold cutting, highly precise contour finishing, milling, drilling, and tapping. Vision Wide manufactured the 5-axis machining center to shorten tool displacement travel and cutting process effectively, and to extend tool lifetime and offer the best choice for composite angle machining. GSF Series had excellent dynamic performance on one-piece structural and equipped high accuracy 2-axis head to achieve 5-axis simultaneous accuracy performance.

•Continuous 2-axis head

•5 axis dynamic rotation synchronization accuracy (TCPM) 0.04mm.

•Built-in Spindle Direct-Driven on B&C axis, 12,000~24,000rpm spindle speed.

•Backlashless driving on B/C axis,Rotation Positioning accuracy ±5”.

•Low table height, closer operating zone, wider door width are convenient design for user.

•Chain type chip conveyor (standard) is able to remove iron chips efficiently.

TAIHO TOOL MFG. CO., LTD.

Product Description :

The AERO series is very suitable for high-power equipment above 80KW.

It has a sharp cutting edges and grooves for great efficiency of discharging the chips. The coating is OSG's diamond coating with glossy surface. This bright and smooth surface optimizes the performance of the end mill, especially in aluminum alloy that weldability and lubricity are required.

The 3-short-blade type and center jet type (AERO-ETS, AERO-O-ETS) are corner radius end mills applied to roughing and finishing.

The 3-long-blade type and extra long blade type (AERO-ETL, AERO-EXTL) are corner radius end mills applied to roughing and finishing.

The 2-short-blade type (DLC-AIR-EDS) is corner radius end mills applied to roughing and finishing.

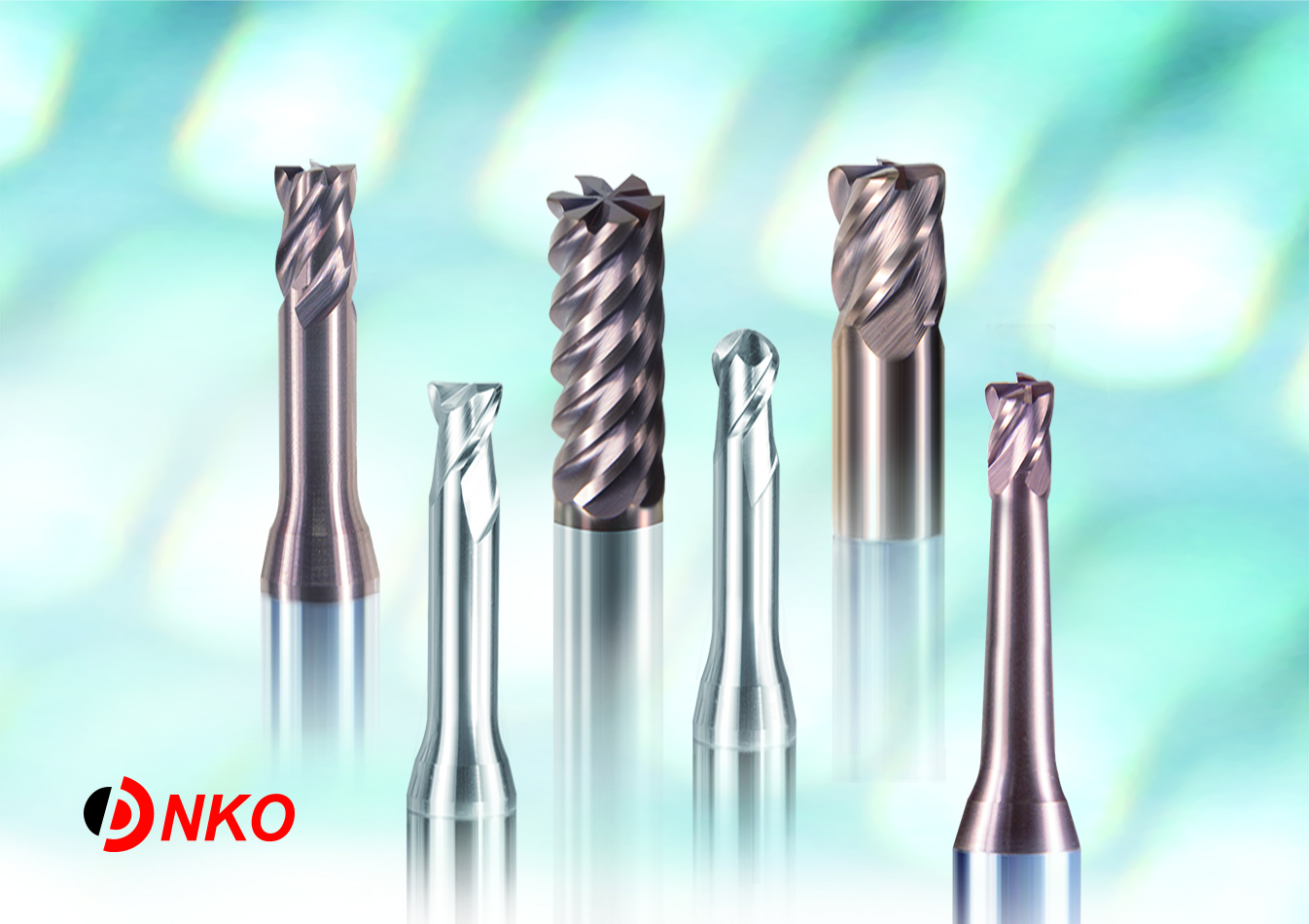

NKO TOOL INC.

Product Description :

End mills for Mould making.

For high-speed machining of Mould and Die materials.

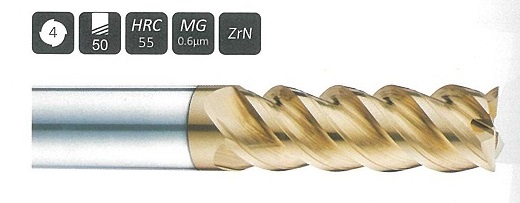

SHARPMAX TOOL INC.

Product Description :

● Engineered with eccentric relief for maximum edge strength in both roughing and finishing applications.

● Variable pitch geometry results in higher quality parts by decreasing chatter and harmonics.

● ZrN coating offers high hardness for estended tool life in high temp alloys and ferrous metals including stainless stee.

CHENG-HSIN PRECISION TECHNOLOGY CORPORATION

Product Description :

☆Wear Resistance

☆Maximized rigidity

☆High Precision

☆Suppresses Vibration

☆Allowing Milling Performance

☆Excellent Surface finishing

☆Surface smoothness

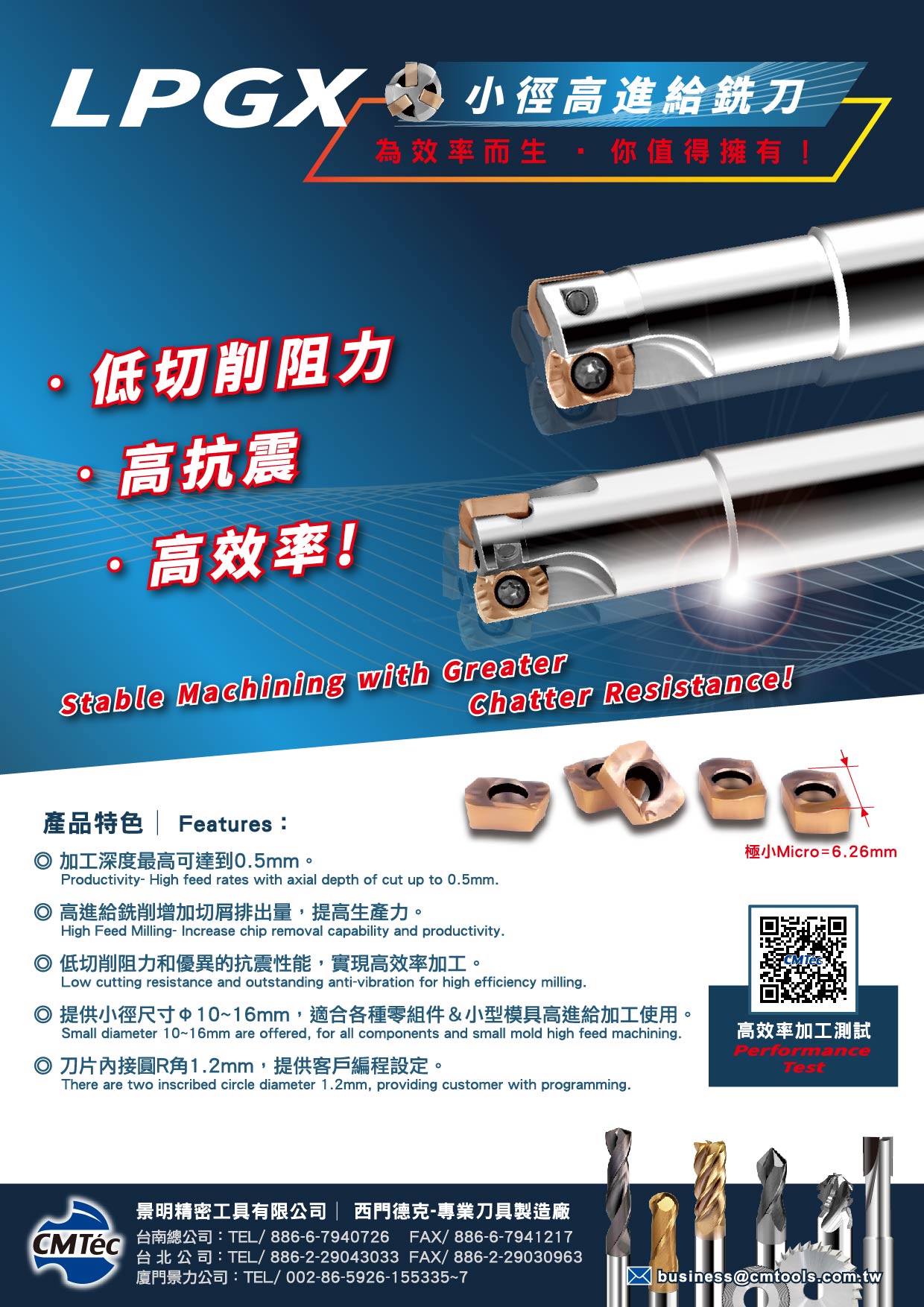

CHIN MING PRECISION TOOLS CO., LTD.

Product Description :

★ Productivity- High feed rates with axial depth of cut up to 0.5mm.

★ High Feed Milling- Increase chip removal capability and productivity.

★ Low cutting resistance and outstanding anti-vibration for high efficiency milling.

★ diameter 10~16mm are offered, for all components and small mold high feed machining.

★ There are two inscribed circle diameter 1.2mm, providing customer with programming.

HON JAN CUTTING TOOLS CO., LTD.

Product Description :

●Internal and external threading for both left-thread and right-thread with one tooling

●Safe machining operation and easier to reach the bottom inside the blind holes

●Evacuate the chip more efficiently than the traditional milling process. shank: 20mm~40mm , Internal Thread Insert: 12I , 14I, 21I, 30I , 40I , External Thread Insert: 14E, 21E, 30E , 40E

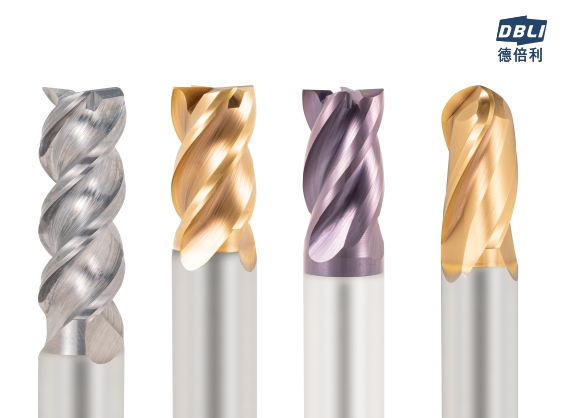

DEEP JET INDUSTRY CO., LTD.

Product Description :

1. Use in high speed machining and hard workpiece machining. It improves the quality and machining speed which is the best choice for precision processing.

◆Carbide Asymmetric Corner Radius End Mill (Steel)-Asymmetric helix angle 40º/42º and unequal flute design to effectively reduce the vibration rate and increase the tool's stability.

◆Carbide Asymmetric End Mill (Aluminum)- Reinforced asymmetric 50/50.5/51 and unequal flute design to effectively reduce the vibration rate and increase the tool's stability. This makes the surface smoother.

◆Carbide Asymmetric End Mill (Steel)-Reinforced asymmetric 36º/38 º design with special grinding technique to reach better surface roughness. Avoid vibration problem during machining and increase tool's stability.

◆Carbide Asymmetric End Mill (Aluminum)- Reinforced asymmetric 44.5º/45º/45.5º design with special grinding technique to reach better surface roughness. Avoid vibration problem during machining and increase tool's stability.