Theme

Digital Transformation

Green Transformation

TAIHO TOOL MFG. CO., LTD.

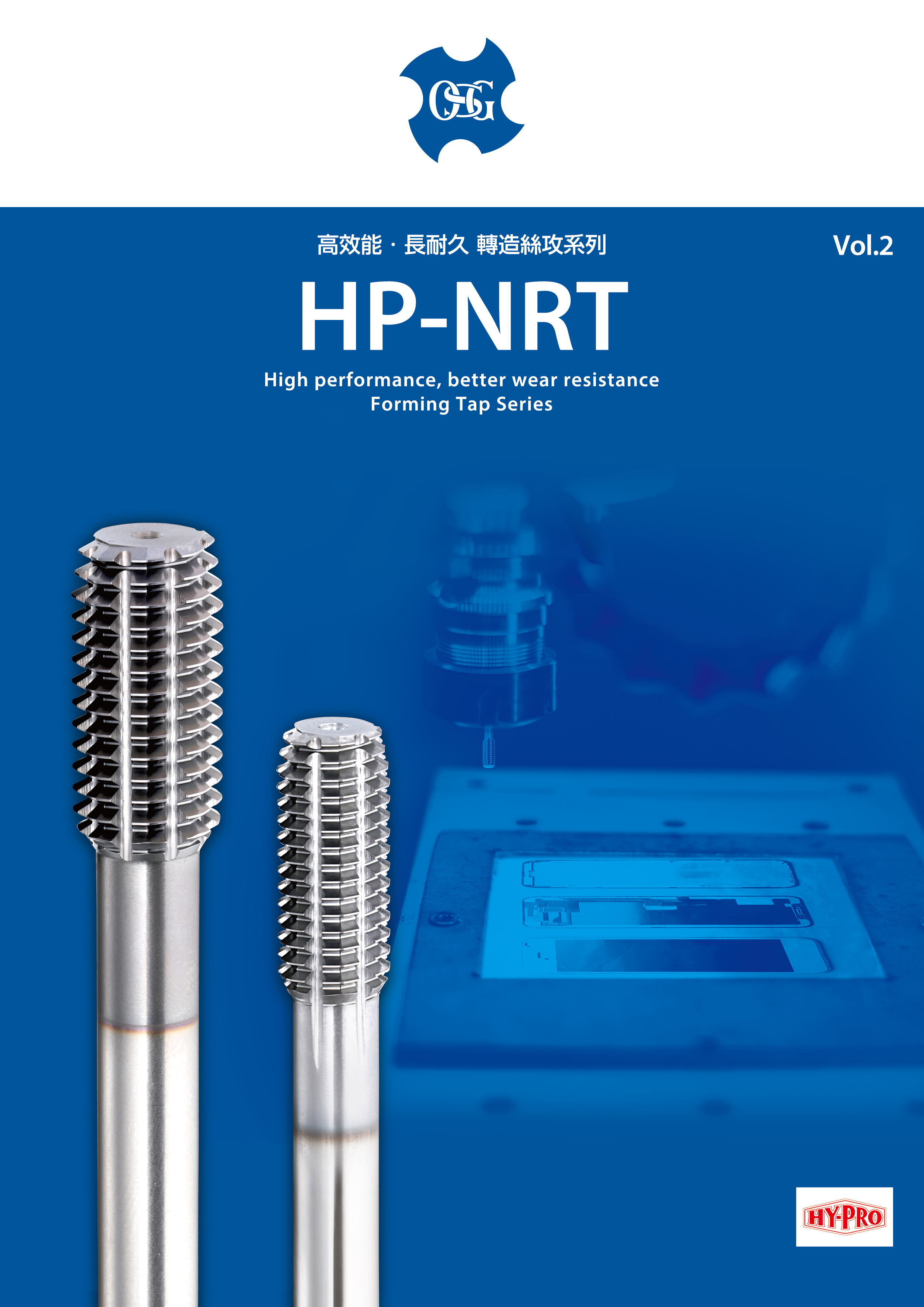

Product Description :

Using powder metallurgy HSS is suitable for high hardness material tapping and stability of the tool life. Special thread design can lower the forming torque and improve the quality of internal thread after tapping. Multi-flutes design can let the cutting oil directly inject into tapping point, which can improve lubricity which effectively control tapping heat and extend tool life. TiCN coating provides welding and wear resistance ,which can lengthen the durability of taps. Special thread design can lower the forming torque and improve the quality of internal thread after tapping. Multi-flutes design can let the cutting oil directly inject into tapping point, which can improve lubricity which effectively control tapping heat and extend the tool life. TiCN coating provides welding and wear resistance, which can lengthen the durability of taps.

HP-NRT series include standard type(HP-NRT), and short chamfer type(HP-SC-NRT).

JIN LI CHENG CUTTING TOOL CO., LTD.

Product Description :

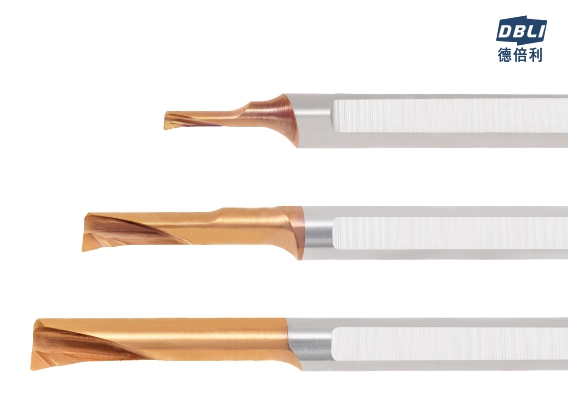

向全球使用金利成刀具的加工航太客戶,深深感謝。

JLC為全球客戶開發了多款加工鈦與WASPALOY及鎳基材料的經典刀款,獲得客戶的持續讚賞與肯定,我們也因為航太客戶的持續互動,一直追求創新與進步。

航空零部件不僅採用了很多新結構、新技術和新材料,零件也越來越講求精密與材料合適性。為了讓客戶在航太的加工上,有更多元的因應方式,我們正式推出新設計的航太特殊材料用刀– AP系列。

整體子彈流動力學的設計理念,與一貫的優質歐系棒材,再搭配更勝一般鈦矽的複合及類鑽鍍層,經過廠內多次的實驗,AP航太系列刀具,絕對讓您面對航太材料加工上游刃有餘。

歡迎全球客戶指教,金利成再次感謝您的支持。

DEEP JET INDUSTRY CO., LTD.

Product Description :

1. With excellent features of coating to increase the tool's wear resistance and thermal conductivity to reduce the chip residue problem.

2. Use special flute design to decrease the chip-off problem during machining.

3. Increase machining accuracy and surface roughness.

7-LEADERS CORP.

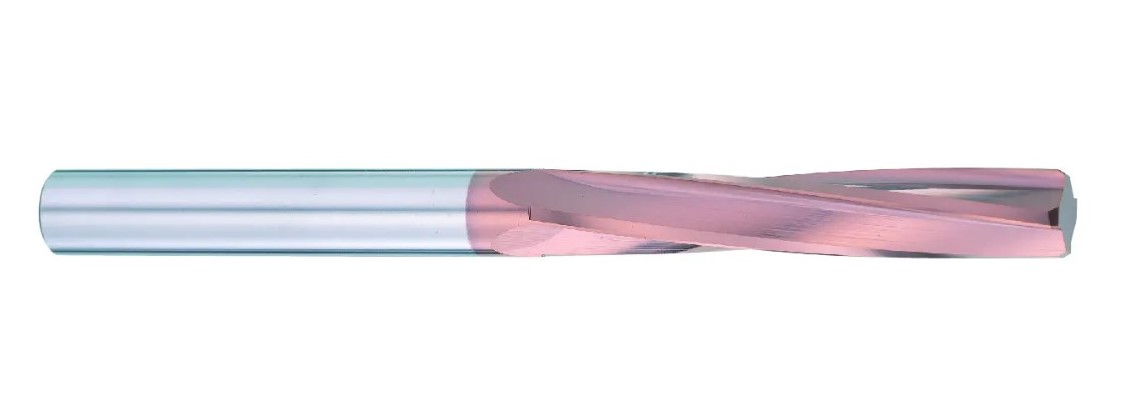

Product Description :

Designed with left helix and right cutting flutes with unequal flute design.

Downward chip evacuation.

Application for reaming different steels below 62HRC, stainless steel, High temp alloys, cast iron, copper…and etc.

Extremely high reaming life with coolant holes for blade cooling.

Nano multilayer coating AlTiSiN with superior wear resistance is suitable for high hardness materials reaming.

Accuracy tolerance: H7 (m5)

0/+0.004mm

HAINBUCH GmbH

Product Description :

Ideal for today's high paced manufacturing environment!

Convenient, that the HAINBUCH quick change-over systems fit on all your machines. Even better, that you can change your clamping devices in a matter of minutes, thus earning money quicker and allowing you to manufacture job-oriented. And, thanks to our unique technology, you will achieve a repeatability of ≤ 0.003 mm on the interface.

However, our high-speed solutions have even more to offer: As you will experience shorter machine downtimes along with reduced processing and throughput times,

your quick change-over systems will pay off in no time. Better yet, you will not have to compromise on quality, rigidity or precision.

Select the spindle connection and the clamping device that is right for you from our extensive assortment. We can even accommodate you if you are already using clamping devices made by other manufacturers. We will simply adapt them to our interface.