Theme

Digital Transformation

Green Transformation

7-LEADERS CORP.

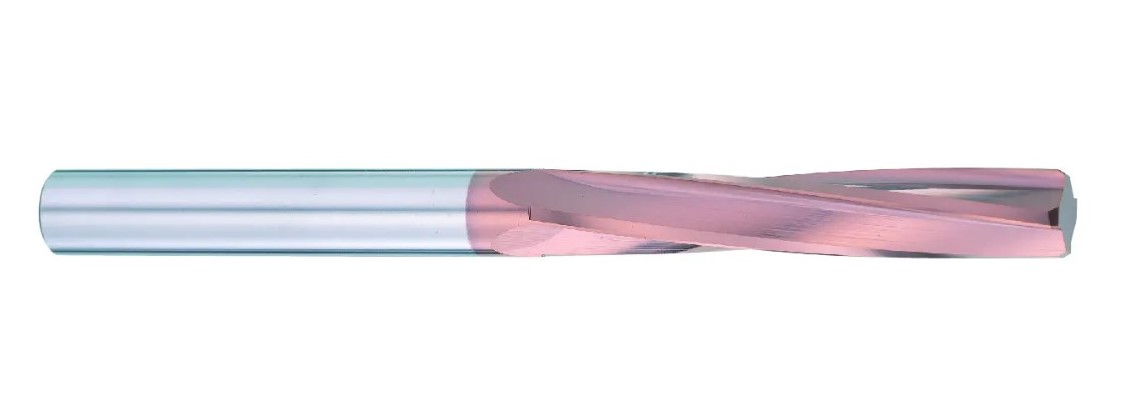

Product Description :

Designed with left helix and right cutting flutes with unequal flute design.

Downward chip evacuation.

Application for reaming different steels below 62HRC, stainless steel, High temp alloys, cast iron, copper…and etc.

Extremely high reaming life with coolant holes for blade cooling.

Nano multilayer coating AlTiSiN with superior wear resistance is suitable for high hardness materials reaming.

Accuracy tolerance: H7 (m5)

0/+0.004mm

Fey Che Trading Co., LTD.

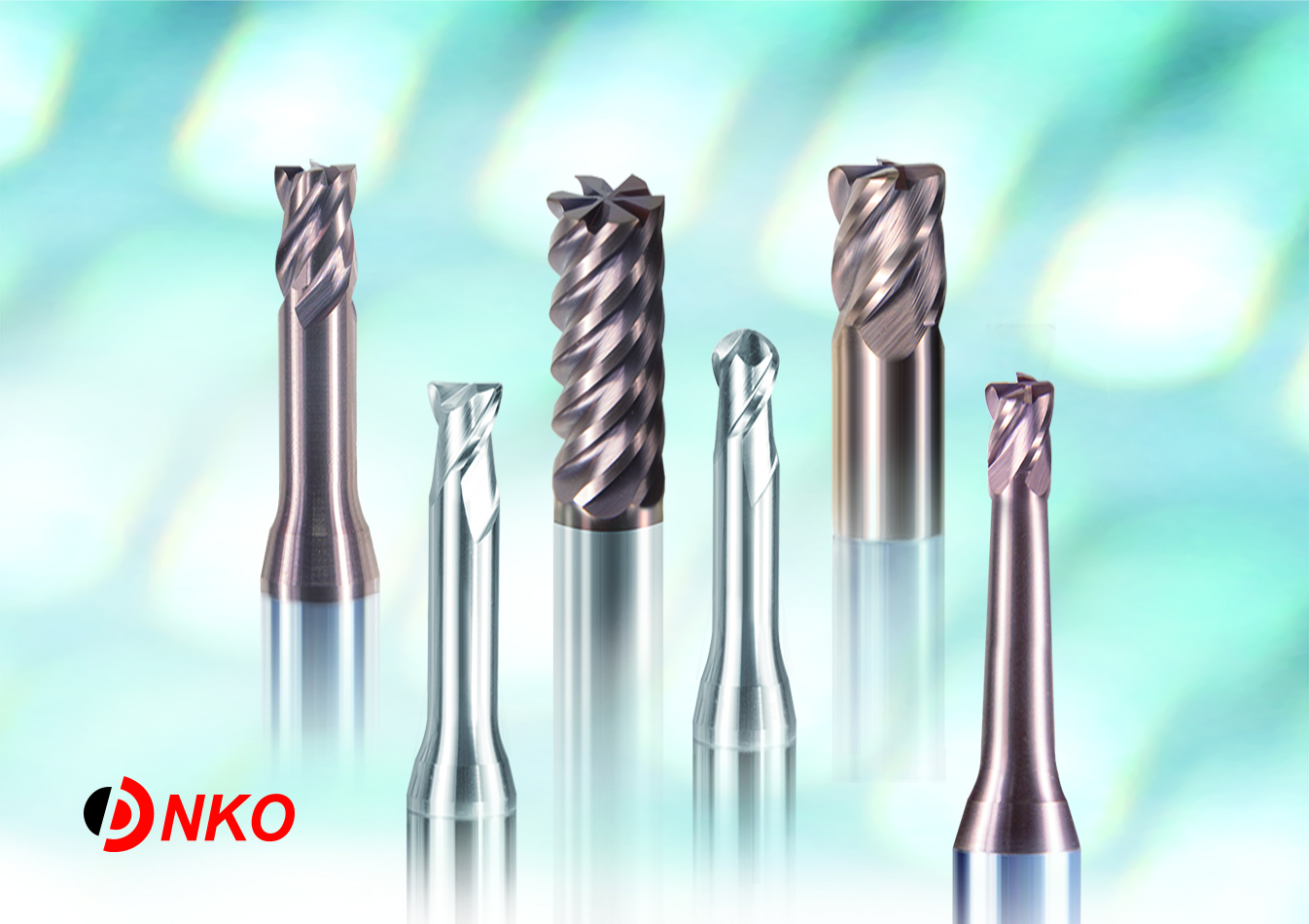

Product Description :

MUGEN COATING PREMIUM Plus具有高抗氧化性和耐磨性,適用於 60HCR 以上的加工。即使在 45~60HRC的加工中也能表現出與 MUGEN COATING PREMIUM 相同的性能。____________________________________________________________

[ 方 頭 銑 刀 ]

[ 型號 : MHDSH445・MHDSH645 ]

*刃長有2D與3D型式可供選擇

*採用最新開發之白金級PLUS無限鍍膜,最適合加工45~70HRC之高硬度鋼材

*高剛性設計實現高精度加工____________________________________________________________

[ 球 頭 立 銑 刀 ]

[ 型號 : MSBSH330-5X ]

*採用耐崩損性佳的新素材及銳角刃口設計,可以減輕切削抵抗

*採用不等分割設計,可以防止震刀

*5軸機專用圓球立銑刀

[ 型號 : MRBSH330 ]

*最優化中心刃形狀、 能進行高切削深的高效率

*加工即使在45〜70HRC高硬度鋼,兼具切削性與

*耐磨耗性,能實現長壽命、高效率的加工

[ 型號 : MRBSH230SF ]

*加工70HRC的高硬度鋼材,也能實現長壽命及穩定的加工性能

*採用耐崩損的新素材及減低切削抵抗的刃口設計____________________________________________________________

[ 端 角 R 立 銑 刀 ]

[ 型號 : MHRSH430RSF ]

*全新的修光刃設計可提升平面加工表面品質

*R角無段差設計,提升側面加工表面品質

*高剛性設計實現高精度加工

TAIHO TOOL MFG. CO., LTD.

Product Description :

Carbide drill applying to EgiAs coating contains wide flute room facilitates stable chip evacuation, and M (Middle) Carbide drill applying to EgiAs coating contains wide flute room facilitates stable chip evacuation, and M (Middle) margin improves stability in deep-hole applications.

The series contain AD-2D/4D (without oil hole), ADO-3D/5D/8D (with oil hole), ADO-10D/15D/20D/30D/40D/50D (deep-hole application with oil hole)

Two point form based on the processing length:Wavy point form with oil hole makes long tool life become possible by breaking chip into small manageable pieces, lowing thrust resistance and stabling torque.

Straight point form with oil hole has both superior point strength and low cutting force.

NINE-9 CUTTING TOOLS CO., LTD.

Product Description :

The “ i-Center ” is a trademark of Nine9,

the developer of the first indexable center drill in the world.(Patented)

Offering an indexable insert system for the 1st time, Nine9’s “i-Center ” design improves your process performance. Shortens set up and center drilling time.Increases tool life and reduces tooling costs.

● High Speed, High Feed Rate

• The special ground insert and rigid holder design facilitate high performance speed and feed rates. For example, drilling alloy steel

at 6000 rpm and feed rate of 600 mm/min. (0.1 mm/rev.).

● Excellent Repeatability

• The positioning repeatability of the insert is within 0.02 mm

(.0008”) in radial direction, thus ensuring conformity to any national

standards.

● Easy Tool Length Setting

• The axial position accuracy of the insert is 0.05 mm (.002”). It is

not necessary to reset the tool length when changing or cutting edge.

● Extended Tool Life

• Coolant can be supplied through the center of the holder to increase performance and extend tool life.

• Insert geometry, grades and coating process are specifically engineered for centering applications.