Theme

Digital Transformation

Green Transformation

HWE DER MACHINERY AND HARDWARE PTY LTD.

Product Description :

High tenacity 0.6u m/m Co10% carbide steel molding.

Abrasion proof lube coating and increase widening flute.

Special unequal end mill angle design,Stainless steels、Titanium alloys、nickel base alloy.

SESAME MOTOR CORP.

Product Description :

The extra high rigidity model is mainly used for extremely large double column machine center or horizontal machine tools. High output torque, high stiffness, no distortion, low backlash, low noise. Service life lubricant, maintenance free.

GREEN ECO PRO CO. LTD.

Product Description :

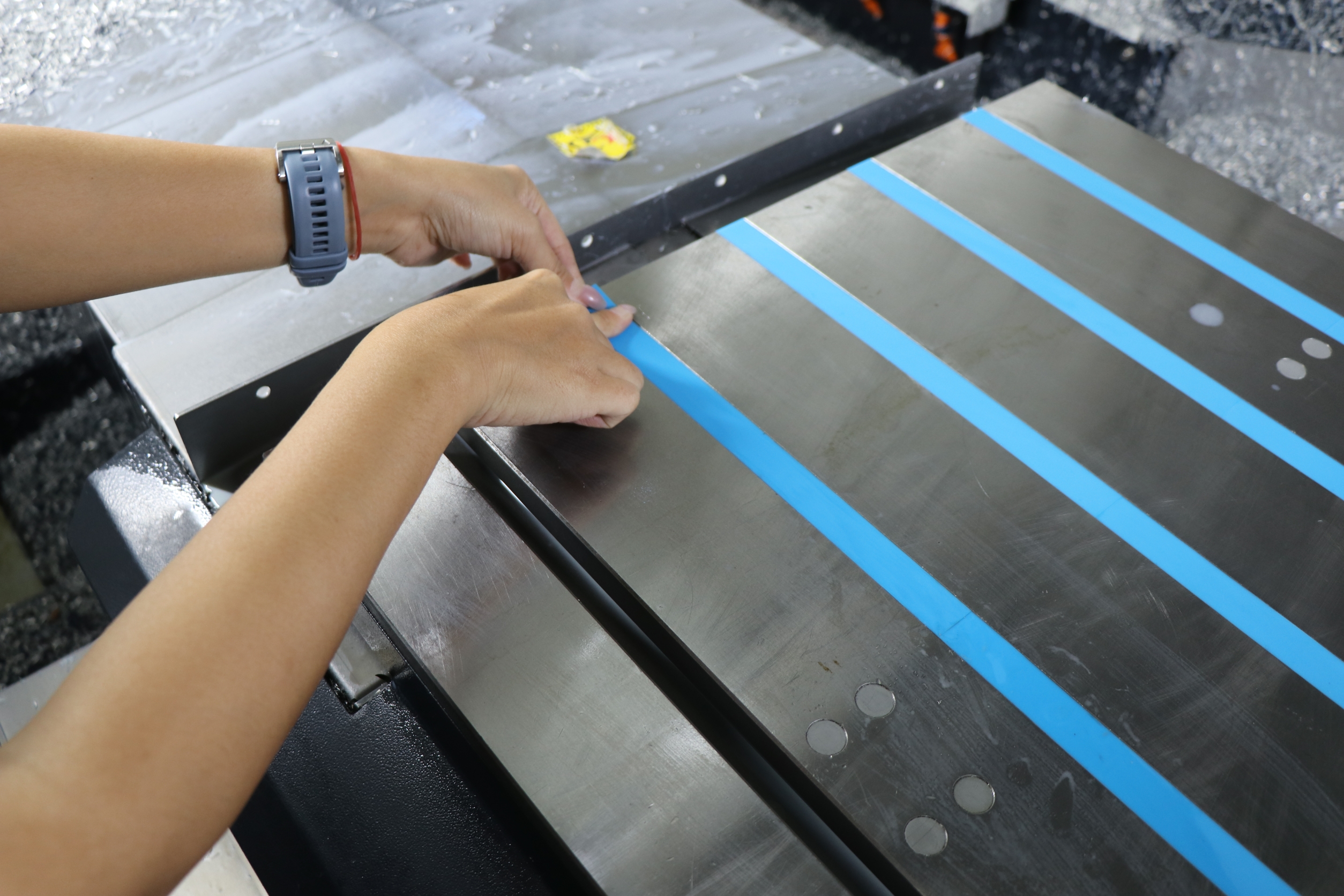

T- slot

The T-slot chip guard is developed to reduce your maintenance time cleaning your machine and changing your work-holding devices. They prevent chips and swarf from filling the T-grooves, which has always been a problem. It is not easy to wash away trapped chips with a coolant wash-down the gun or an air gun. The material is high-temperature resistant, flexible, and washable. In addition, it is extremely durable for dry machining applications. Overall, they look great and the kit is very affordable/cost-effective.

SONG GIA INDUSTRIAL CO., LTD.

Product Description :

Hole deflection within 0.004

■Choose Machine : Star SR-20RIV SR-32J

■Detailed specifications

△Speed ratio :1:1

△Maximum speed : 6000RPM

△Tool clamping : ER16M/ER11M

△Reference code :0M155

https://www.songgia.com.tw/en/products/3-spindle-double-drilling-milling-unit-stra2b3201

YOKE INDUSTRIAL CORP

Product Description :

•Rotates through 360° and pivot 180°, and simultaneously allows lifting from any direction.

•Manufactured from forged alloy steel, quenched and tempered.

•Manufactured and tested in accordance with EN1677-1.

•Load rated parts are 100% magnaflux crack detected.

•Individual forged parts and cap screw are traceable to Test Certification.

•Bolt are Metric thread (ASME / ANSI B18.3.1M).

•Proof tested to 2.5 times the WLL.

•Fatigue rated to 1.5 times the WLL.

•All YOKE Lifting points meet or exceed all the requirements of ASME B30.26.

•Quick and simple assembly, just a tapped hole is required.

SING CHIUN ENTERPRISE CO.,LTD.

Product Description :

(一) MS CONNECTOR ( MIL-DTL-5015 )。

(二) SLS ELECTRON CONNECTORS ( Square receptacle )。

(三) SLT ELECTRON CONNECTORS ( Circular receptacle )。

(四) JN1 ELECTRON CONNECTORS。

(五) CM10 ELECTRON CONNECTORS。

(六) HARTING EUROPEAN HEAVY DUTY CONNECTOR。<br />

BORE AUTOMATION TECH. CO., LTD.

Product Description :

40 PIN Interface Module, equipped with WAGO PUSH-IN Type PCB terminal block, indication LED's for output status , with high quality IDC/MIL connector, fully compatible with variety PLC/CNC controller, Ultra-narrow, space-saving

DA CEI TRADE CO.,LTD.

Product Description :

This device is used in conjunction with the DC-800 laser cleaning machine to clean the socket probe, significantly improving stability and cleaning efficiency. It eliminates the need for manual cleaning and avoids direct contact with laser light.

ASMITH MANUFACTURING COMPANY

Product Description :

★Handle: FRP has high stiffness and high loading. Load capacity 60 kgf, it is very light and an insulator to electronics. Users will not be frostbitten when the operating temperature is frozen.

Holder: The hole pitch can be adjustable within 18mm, easy to install. Waterproof (IP66). Working temperature is -20℃~150℃, resistance to acid, alkali, and greasiness.

Two ways for install: 1. Inner stationary type. 2. Outside stationary type.

In accordance with RoHS.

➤Material-Handle : Fibre-reinforced plastic(FRP), Black or Silver

➤Material-Holder : Polyamide(PA6-GF33), Black or Silver.