Theme

Digital Transformation

Green Transformation

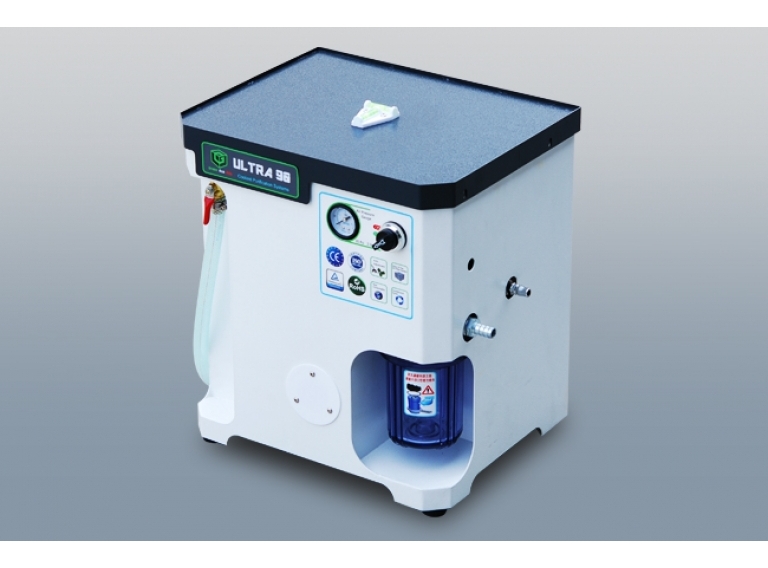

GREEN ECO PRO CO. LTD.

Product Description :

Chip Vacuum Removal System

FC Series

Used by Negative vacuum principle, and increase high absorption of air to get filter cycle. Intercept particulate matter and impurity.

Processing cycle

Zero Power consumption

CNC Machine No Stop

Waste material a few water

No Consumable

Reduce wastage of coolant

Promote Volume of Water Tank

Promote productivity

GREEN ECO PRO CO. LTD.

Product Description :

concentration on basic, To reduce floating oil on surface and prevent anaerobic bacteria and acidification of coolant. Solve the foul smell、Keep stable PH value、Save cost.

Oil reservoir capacity

Zero supplies

Patented technology - SKIMMER

Patented technology - S.T.P.M

Processing cycle

Small volume

Zero Power Consumption

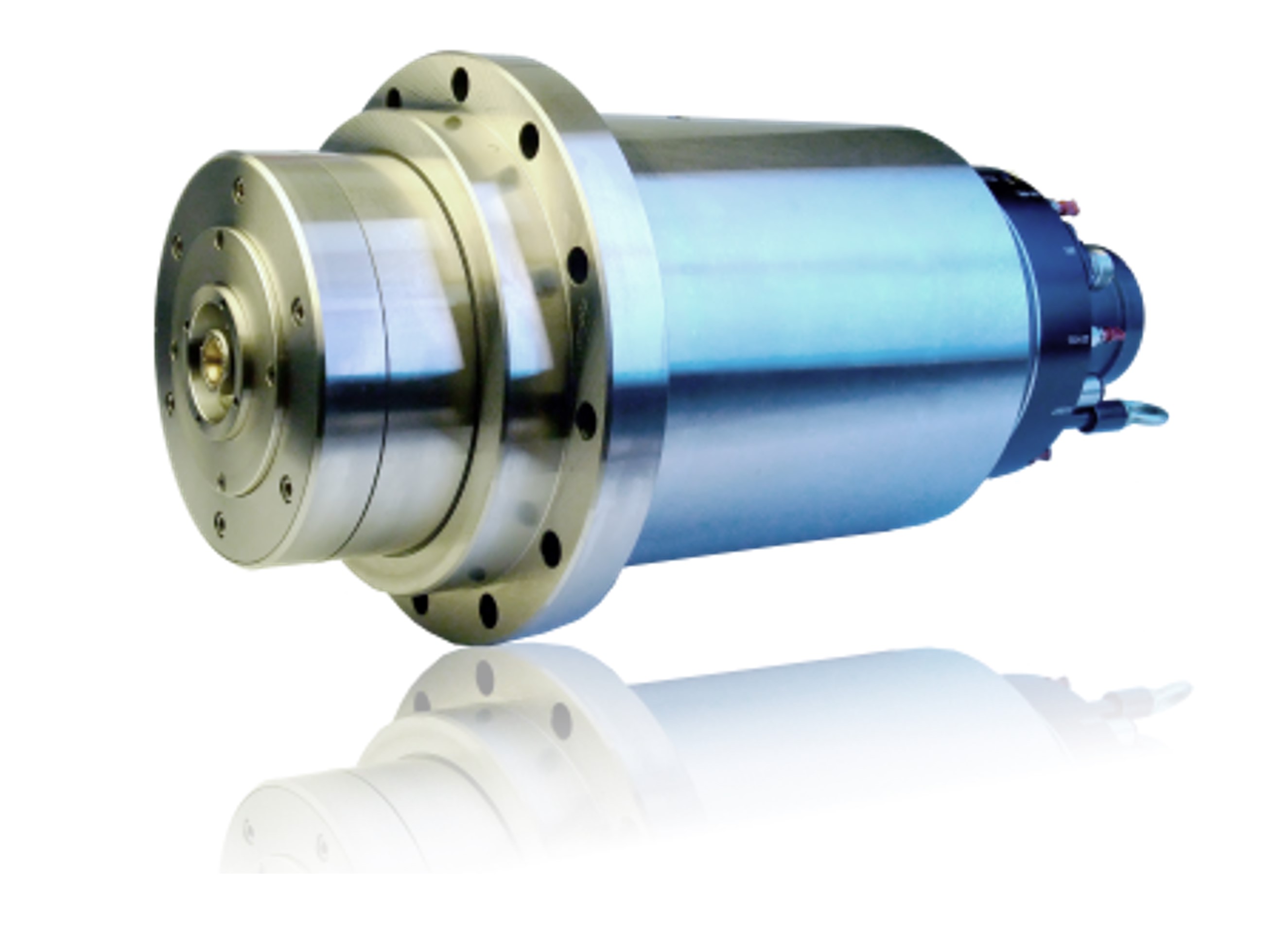

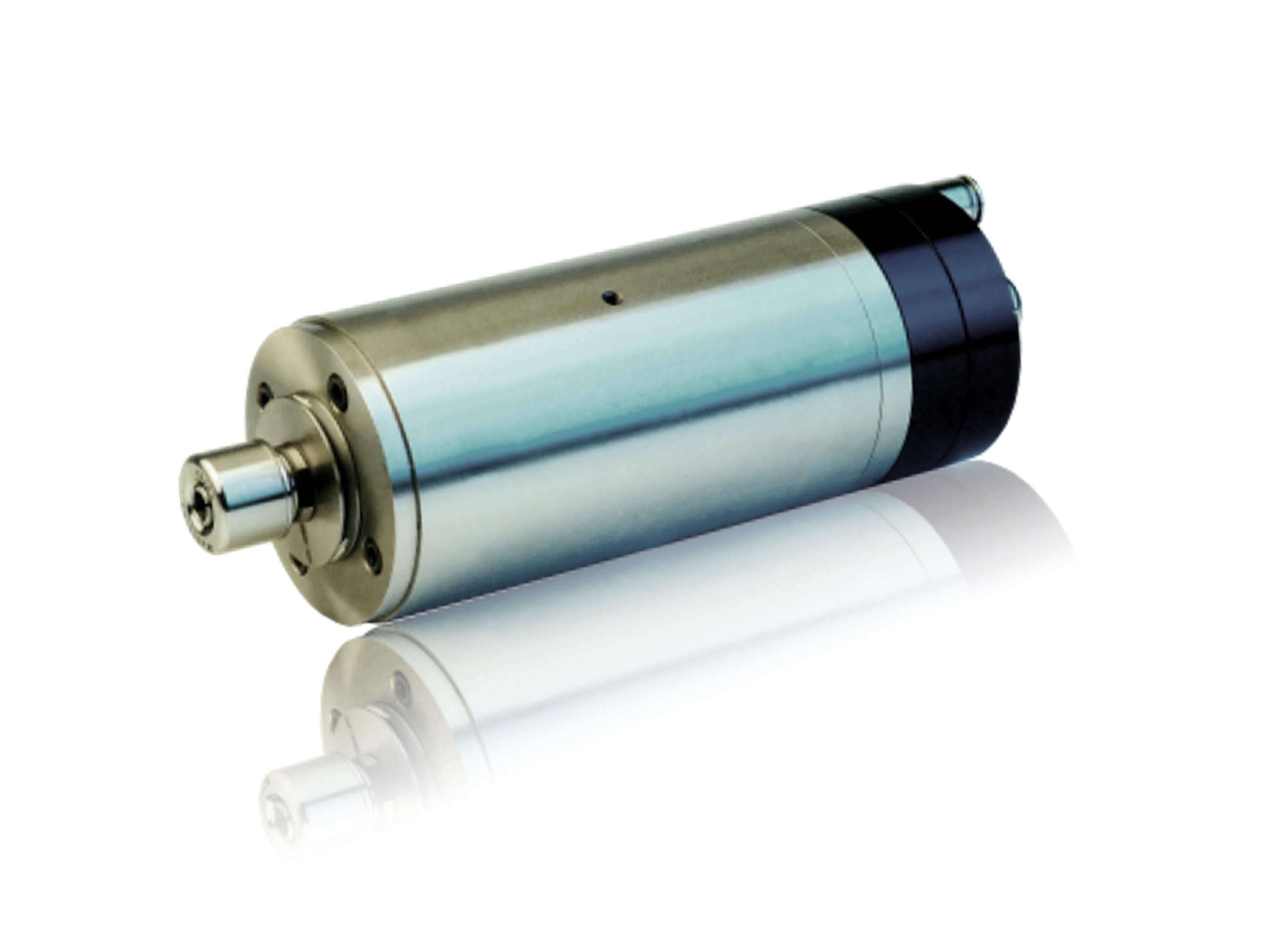

MONGTEC PRECISION INC.

Product Description :

◎ The general spindle speed is only 6000-15000rpm, and the tool can be pushed up to 55000rpm through 15-70bar coolant pressure, saving 70% of cycle time

◎ Various interfaces can choose BT/HSK/ER/PCS/straight

◎ Tool can be changed by ATC

◎ Display processing tool speed with chip transmission

◎ Excellent run out within 0.003mm

HAINBUCH GmbH

Product Description :

HAINBUCH segmented mandrels use state-of-the-art clamping technology that is convincing, even in the most critical applications. The central element is the vulcanized segmented clamping bushing. Because conventional clamping bushings are made of spring steel and are only annealed to spring hardness, they are »soft« and they must »bend« to clamp the workpiece. HAINBUCH segmented bushings are made of case-hardened chromium-nickel-steel and have segments that are extremely hard and rigid. All contact surfaces are completely ground in one operation guaranteeing optimum concentricity.

Mandrels with hexagonal clamping geometry, the MAXXOS mandrels. are the optimized version for round MANDO mandrels. Thanks to the hexagonal geometry, a previously unattained clamping force and rigidity with the best precision is now achieved for internal clamping. The robust and powerful clamping mandrel delivers first-class values in terms of dirt density. The force is transmitted by positive locking, in addition to optimum process reliability and long maintenance intervals.

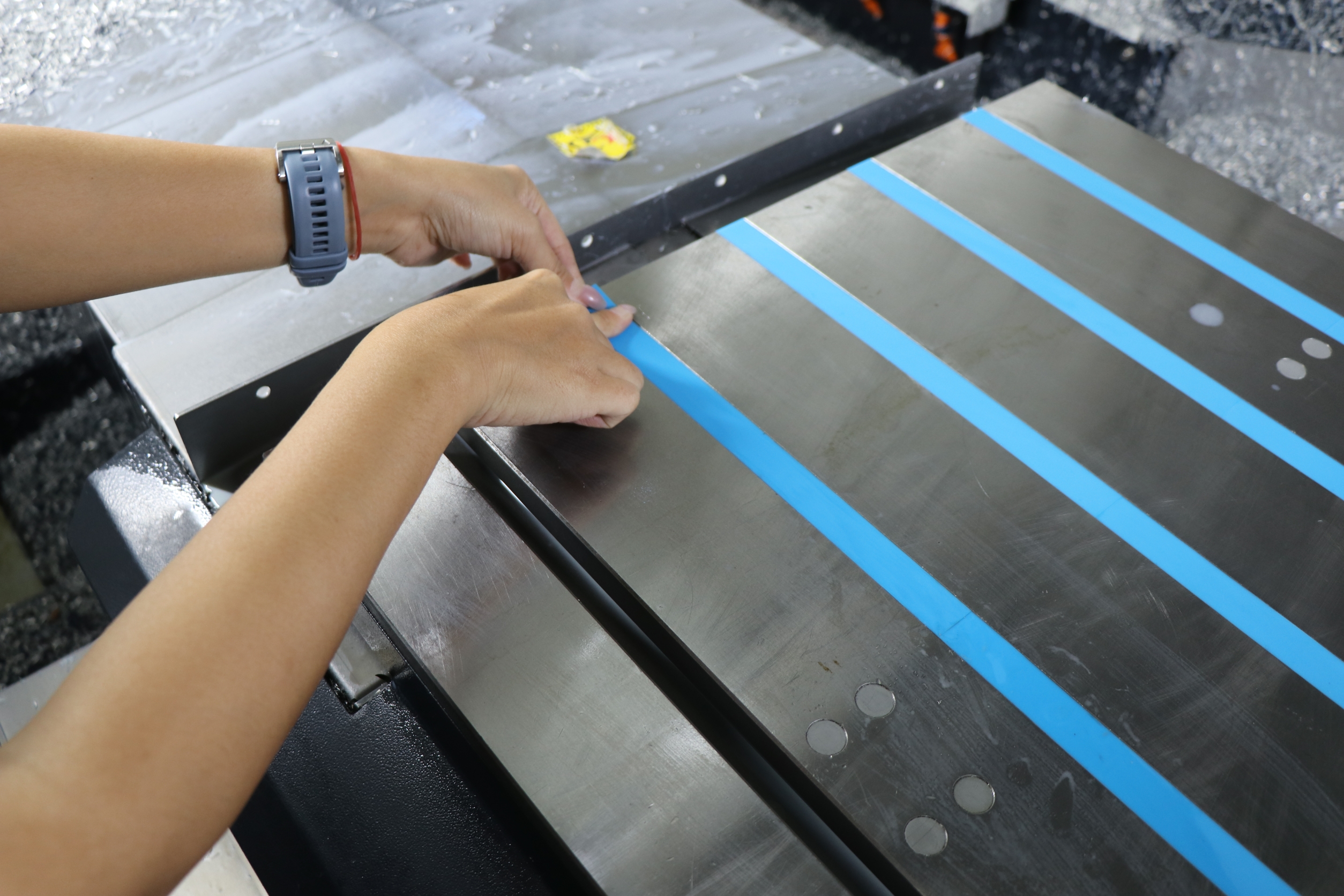

GREEN ECO PRO CO. LTD.

Product Description :

T- slot

The T-slot chip guard is developed to reduce your maintenance time cleaning your machine and changing your work-holding devices. They prevent chips and swarf from filling the T-grooves, which has always been a problem. It is not easy to wash away trapped chips with a coolant wash-down the gun or an air gun. The material is high-temperature resistant, flexible, and washable. In addition, it is extremely durable for dry machining applications. Overall, they look great and the kit is very affordable/cost-effective.

AUTOGRIP MACHINERY CO., LTD.

Product Description :

◎ Second Collet Changes Slash Setup Times.

◎ Industry-Leading Gripping Range.

◎ Ultra-Precision Accuracy.

◎ Parallel clamping over the entire clamping length

◎ Extreme Grip Force = Most Aggressive Chip Removal/Fastest Cycle Times.

◎ Maximum Rigidity Produces Superior Part Finishes.

◎ Best Tool Clearance - Critical For Live Tooling.