Theme

Digital Transformation

Green Transformation

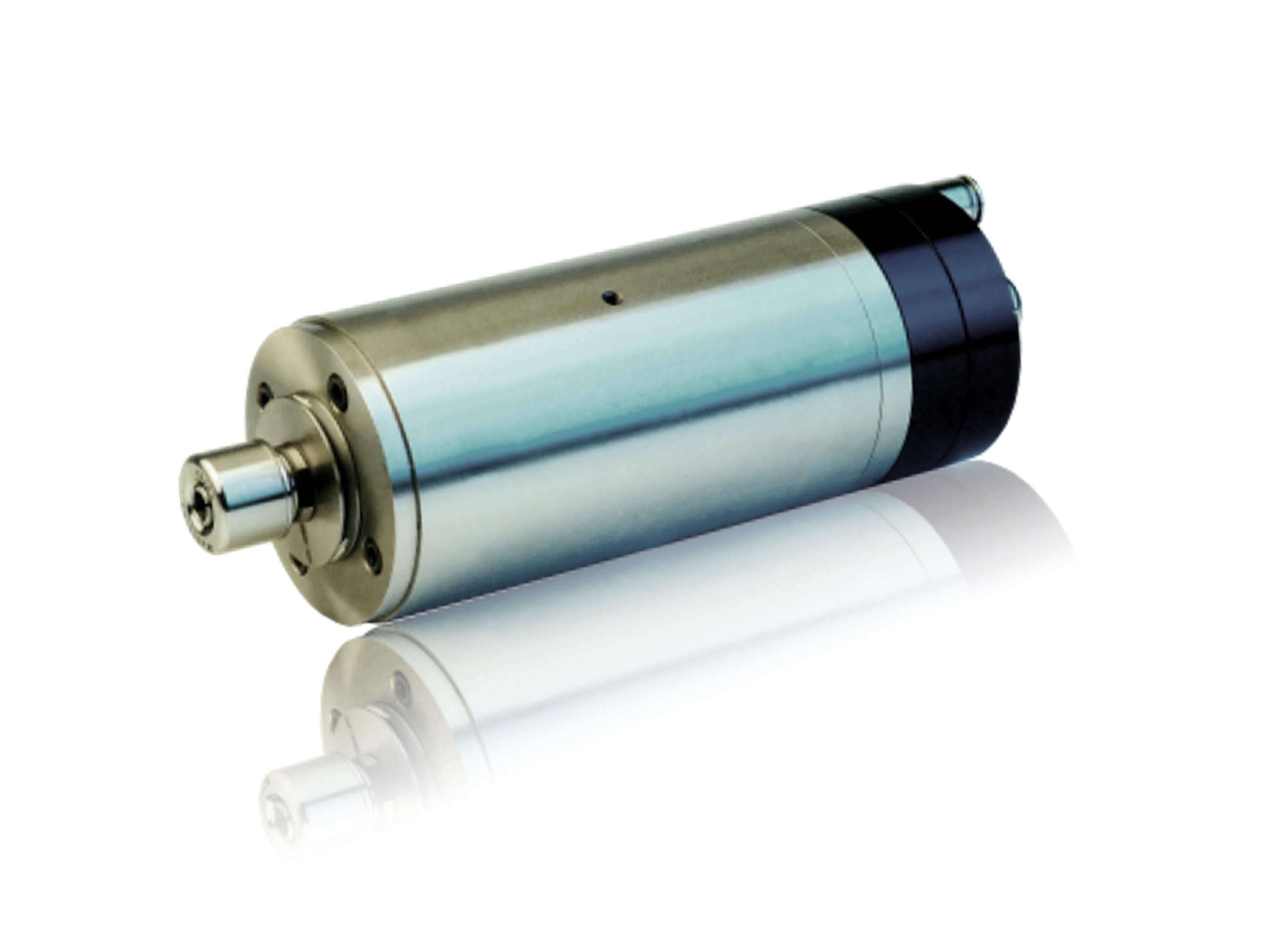

SPINDLEX TECHNOLOGIES CO., LTD.

Product Description :

Spindle housing diameter : 45mm

Tool interface : SD6

Maximum speed (rpm) : 50000 RPM

Lubrication : Grease

Motor power : 0.45/0.54 Kw

SPINDLEX TECHNOLOGIES CO., LTD.

Product Description :

Spindle housing diameter : 120mm

Tool interface : Quill D22/38 M22XP2.0

Maximum speed : 42,000 RPM

Lubrication : Oil-Air

Motor power : 11.5/17 Kw

XIN GONG YANG MACHINERY CO., LTD.

Product Description :

◎Spindle Motor:Permanent Magnet Synchronous Motor22W(30HP)

◎Max. Diameter of Cutter:Ø300

◎Feed Travel:500mm

◎Speed Change Method:Manual/12 Section

Tokai Spring industries, Inc.

Product Description :

Tokai spring is committed to manufacturing small-lot and custom-made spring orders because we believe that there are customers who need highly specialized, high quality spring products. Tokai spring’s mission is satisfying or even exceeding our customer’s requirements.

GREEN ECO PRO CO. LTD.

Product Description :

Precision filtration system

Due to different grinding and processing materials, the particle size, quality, and hardness of the materials to be filtered will also vary. For this reason, our filtering equipment was designed, which can be used for quartz, silicon carbide, semiconductor grinding, electrical discharge machining, or high precision requirements and can effectively intercept fine impurities.

Continuous/batch processing

Customized tungsten steel stirring motor

Filter material saturation alarm

AUTOGRIP MACHINERY CO., LTD.

Product Description :

Brand new upgrade! Introducing the Grip Force Sensor (GFS-100) with advanced gripping technology. Bluetooth 5.0 ensures exceptional wireless connectivity, making your operations smoother. Convenient Type-C charging interface for easy charging, providing continuous power for your work. The high-performance lithium battery offers extended battery life, eliminating concerns about power shortage during work and allowing you to focus on your tasks. GFS-100 supports both Android and iOS systems, ensuring seamless compatibility for a user-friendly experience. With the flexibility to configure as a 2-claw or 3-claw operation based on your actual needs, it provides greater operational versatility. Upgrade your work experience with GFS-100, showcasing the convenience and efficiency of cutting-edge technology.

GREEN ECO PRO CO. LTD.

Product Description :

Chip Vacuum Removal System

FC Series

Used by Negative vacuum principle, and increase high absorption of air to get filter cycle. Intercept particulate matter and impurity.

Processing cycle

Zero Power consumption

CNC Machine No Stop

Waste material a few water

No Consumable

Reduce wastage of coolant

Promote Volume of Water Tank

Promote productivity

AUTOGRIP MACHINERY CO., LTD.

Product Description :

Whole stroke position montoring.Position setup by teach-in function.No more manual adjustion is required as the case of proximity switch.Save machine idle time .Compatible with PLC programing.

HAINBUCH GmbH

Product Description :

The HAINBUCH SYSTEM allows you to clamp 1,000 different workpieces and gives you everything you need for complete machining.

You need only one basic clamping device – a chuck or a stationary chuck that remains on the machine. For O.D., I.D., jaw or magnetic clamping, or clamping between centers you then use adaptations – without having to accept any compromises.

The workpiece defines the adaptation and converts your basic clamping device for the particular application. This incredible solution reduces set-up time substantially, while increasing flexibility and making it possible to easily squeeze in short-term jobs.

HAINBUCH GmbH

Product Description :

Ideal for today's high paced manufacturing environment!

Convenient, that the HAINBUCH quick change-over systems fit on all your machines. Even better, that you can change your clamping devices in a matter of minutes, thus earning money quicker and allowing you to manufacture job-oriented. And, thanks to our unique technology, you will achieve a repeatability of ≤ 0.003 mm on the interface.

However, our high-speed solutions have even more to offer: As you will experience shorter machine downtimes along with reduced processing and throughput times,

your quick change-over systems will pay off in no time. Better yet, you will not have to compromise on quality, rigidity or precision.

Select the spindle connection and the clamping device that is right for you from our extensive assortment. We can even accommodate you if you are already using clamping devices made by other manufacturers. We will simply adapt them to our interface.