Theme

Digital Transformation

Green Transformation

TAIKI INDUSTRIAL CO., LTD.

Product Description :

The aluminum round jaws(FW-A10050) are suitable for extra bigger outer dia. (thin pipe.).

This type of round jaws can cover the outer dia. of work piece enable to decrease deformation and increase the accuracy.

For example: Type of FW08 can hold parts with outer dia. of 200mm.

AUTOCLAWS PRECISION MACHINERY CO., LTD.

Product Description :

1. Suitable for round-bar shape objects to clamp before cutting process.

2.Using the advanced high-strength alloy steel, the key components have been treated with hardening which is strengthening the structure and enhancing the stability with accuracy and durability.

3.Large caliber design allowing the bar material go through, furthermore, it can be complemented to automatic processing eqipment for enhancing the machining efficiency.

4. The chucks complement the rotary hydraulic cylinder to provide a stable pressure for various chucking conditions.

5. Professional precision grinding makes it high-precision, precision repeat clamping accuracy, high clamping force.

A Being Kou Tools Co., Ltd.

Product Description :

MicroCentric was founded in 1969. 50 years of advancing engineering and high-quality manufacturing has earned MicroCentric the reputation as the global leader in precision workholding technology. Each MicroCentric product is backed by superior design, the highest quality materials and precision workmanship for reliable, long term performance and unmatched accuracy.

MicroCentric is renowned for building workholding products of unmatched precision and accuracy. Most MicroCentric’s precision chucks have a standard repeating accuracy of .0001″ (0.002mm), and many models are accurate to within .00005″ (0.001mm).

AUTOCLAWS PRECISION MACHINERY CO., LTD.

Product Description :

1.Push type collect chuck fixtures can perform high accuracy of axial position locating by the components and mechanical structure design.

2.The collect chuck could be installed onto the lathe machines rapidly and easily without changing the pulling-pipe when it is switched with the exist chuck.

3.Quick-dismantling design: The front cover can be quickly removed

Simply replace the elastic clip can be replaced to immediately turn different sizes or shapes (round, square, hexagonal...) for increased efficiency and versatility.

4.The components through special technology of hardening treatment to archive high intensity,high rigidity and well durability.

5.Professional precision grinding makes it high-precision, precision repeat clamping accuracy.

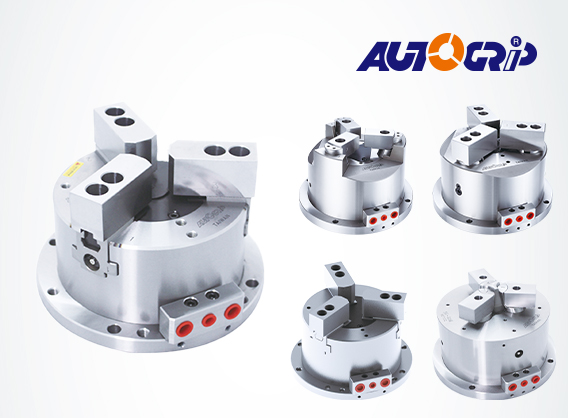

AUTOGRIP MACHINERY CO., LTD.

Product Description :

For stationary chuck, there are pull back, pull lock, thru-hole/non-thru-hole stationary chucks in the category.Multi-plate.4-plate(MP4)=>

For milling machine / machine center.

Allow simultaneous machining with up to 4 grippers.

(Order can be customized for 2,3,6 grippers).

Work with SP/SD/SU/SE vertical chuck.

Driven by Hydraulic or Pneumatic.

Individual circuit for each chuck.

Special design and reduce the height of working surface.

Lock valve unit (option).

Air tight detection function(option).

HAINBUCH GmbH

Product Description :

The HAINBUCH SYSTEM allows you to clamp 1,000 different workpieces and gives you everything you need for complete machining.

You need only one basic clamping device – a chuck or a stationary chuck that remains on the machine. For O.D., I.D., jaw or magnetic clamping, or clamping between centers you then use adaptations – without having to accept any compromises.

The workpiece defines the adaptation and converts your basic clamping device for the particular application. This incredible solution reduces set-up time substantially, while increasing flexibility and making it possible to easily squeeze in short-term jobs.