Theme

Digital Transformation

Green Transformation

GP MACHINERY CO., LTD.

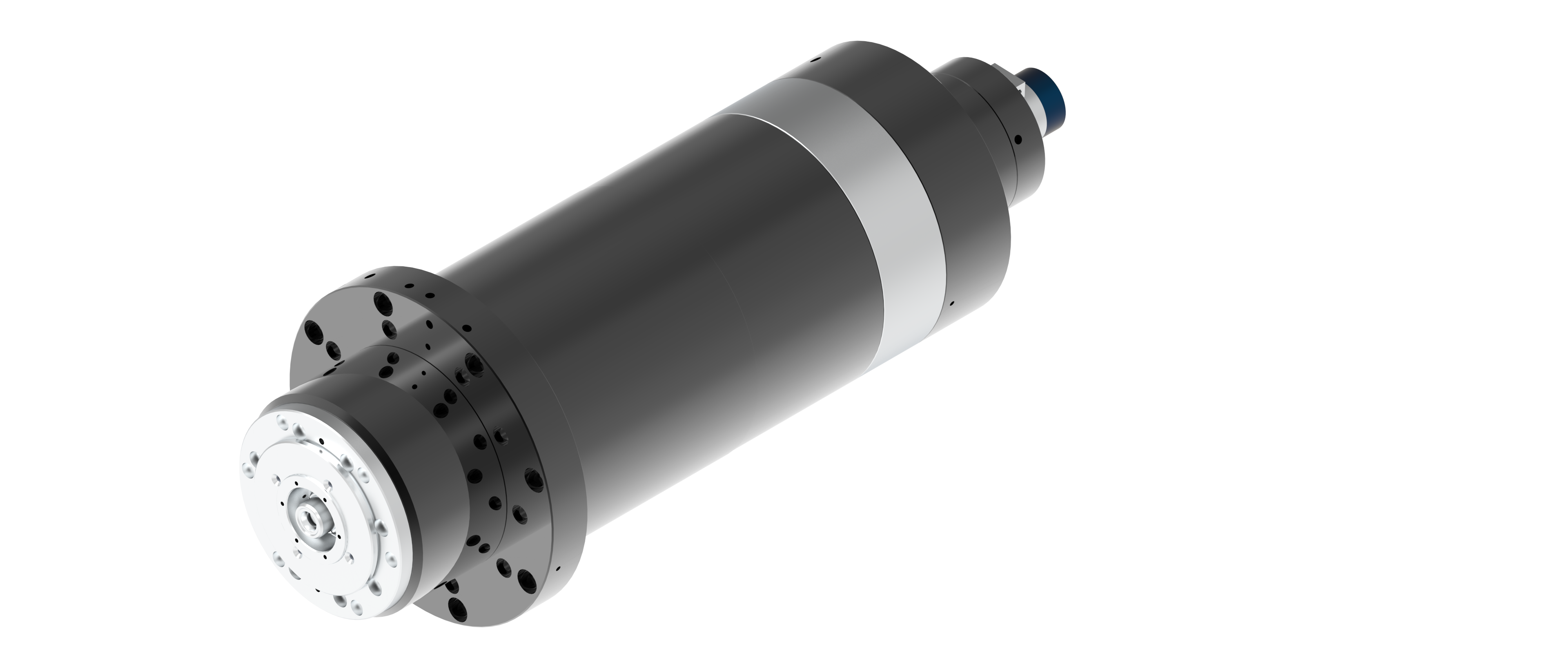

Product Description :

Built-In Spindle

◆ Lightweight design.

◆ After the mandrel is cryogenically treated, the heat variable is small and the machining accuracy is excellent.

◆ The internal cooling system adopts spiral circulation to achieve high-efficiency operation.

◆ The spindle adopts ceramic ball bearings from Europe to achieve optimal power and excellent rigidity.

◆ With standard accessories bearing temperature sensor PT-100.

GP MACHINERY CO., LTD.

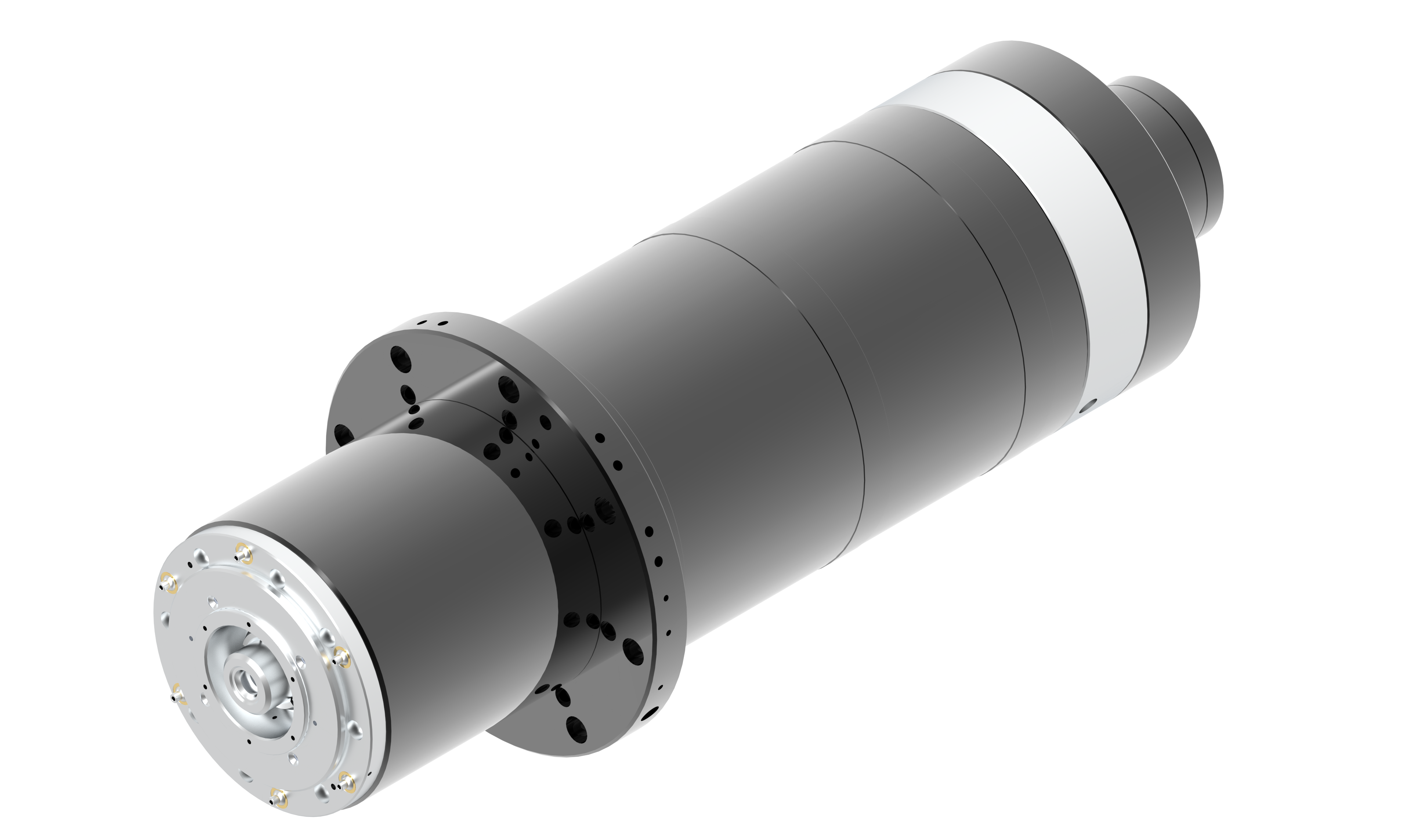

Product Description :

Built-In Spindle

◆ Lightweight design.

◆ After the mandrel is cryogenically treated, the heat variable is small and the machining accuracy is excellent.

◆ The internal cooling system adopts spiral circulation to achieve high-efficiency operation.

◆ The spindle adopts ceramic ball bearings from Europe to achieve optimal power and excellent rigidity.

◆ With standard accessories bearing temperature sensor PT-100.

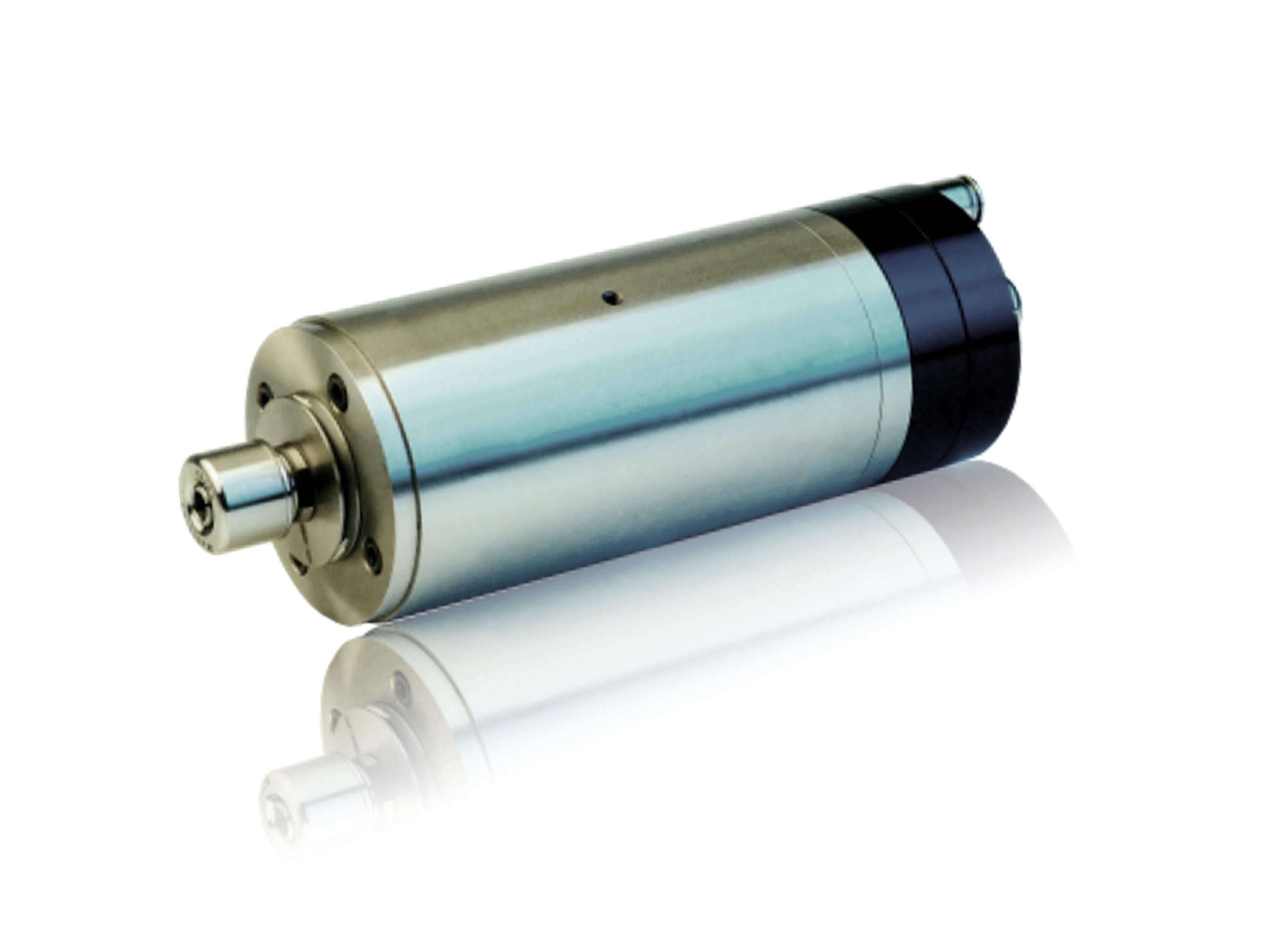

ROYAL PRECISION TOOLS CORPORATION

Product Description :

▶High speed

▶High precision, high efficiency

▶High dynamic rotary accuracy

▶Balancing adjustment within G1, low vibration

▶Modularized easily

▶Thermal displacement, high stability

▶Short overall length, low inertia

▶High motor power, high moments of inertia

▶Applications: Milling, turning, mill-turn, multi-spindle

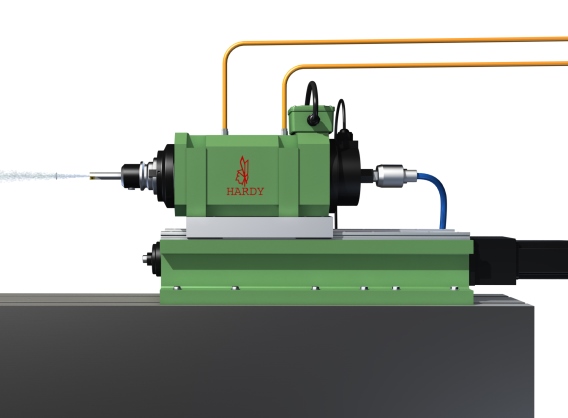

GIFU ENTERPRISE CO., LTD.

Product Description :

Model:Semi-Auto 500 Extension Milling Head(Maximum Torque:700N.m) (Maximum RPM:3000r.p.m)

1.High torque transmission and high cutting efficiency.

2.The linkage spindle design makes the easy tool loading.

3. The design of extension body is exquisite with solid structure.

4.High accuracy, low vibration and good dynamic rotation accuracy.

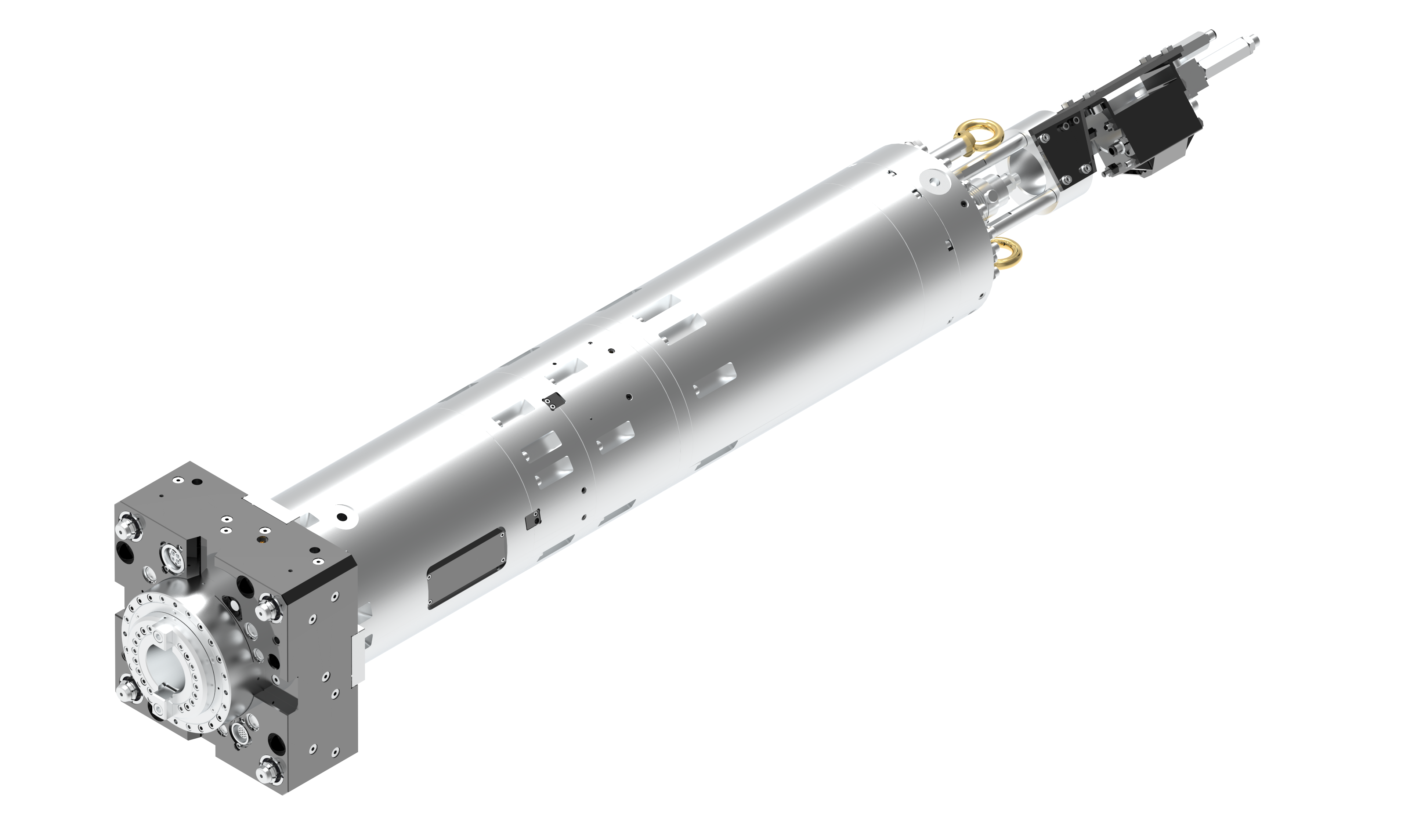

GP MACHINERY CO., LTD.

Product Description :

Features:

The RGB system (Ram Gear Box) is the most complete solution within this family, with important technological contents, that combines high torque performance in small dimensions particularly appreciated for vertical (gantry or double column) and horizontal axis machine tools. The general characteristics are similar to the RTS

Products:

.Automatic attachment system for the accessories (like heads or extensions)

.Multitasking machining operations.

.Easiness of assembly and maintenance on the machine with:

.Quick connections and couplings positioned at the top of the RAM

.Possibility of easy and quick extracion of the spindle from the front of the RAM.

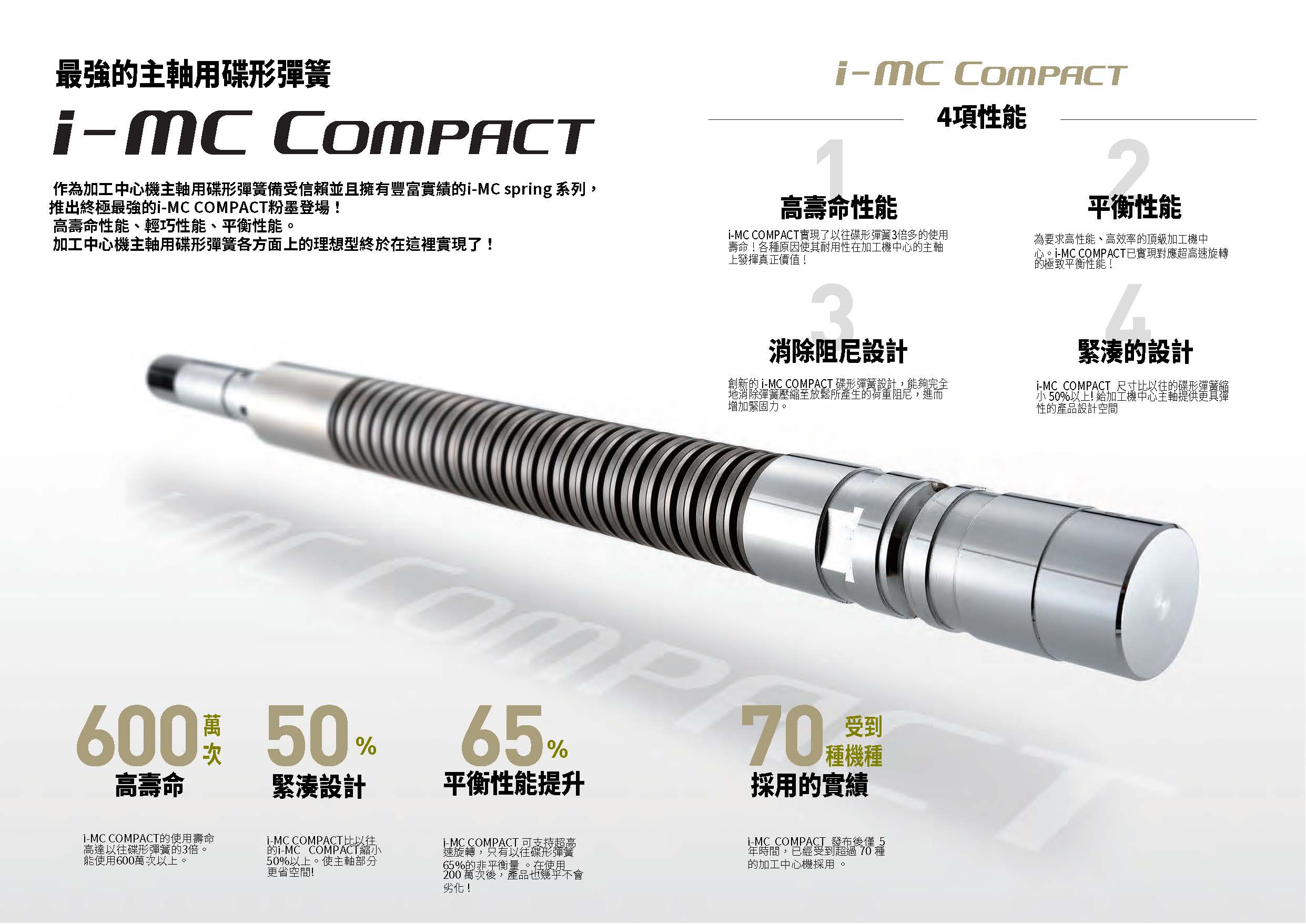

Tokai Spring industries, Inc.

Product Description :

i-MC spring series has established a strong trust and reputation as disc springs for the main spindle on machining centers among manufacturers. i-MC COMPACT is a new and innovative product of i-MC spring series.

Long-life performance, compact performance and balance performance.

In all of these aspects, this new product achieves the ideal form of disc springs for the main spindles on machining centers.