Theme

Digital Transformation

Green Transformation

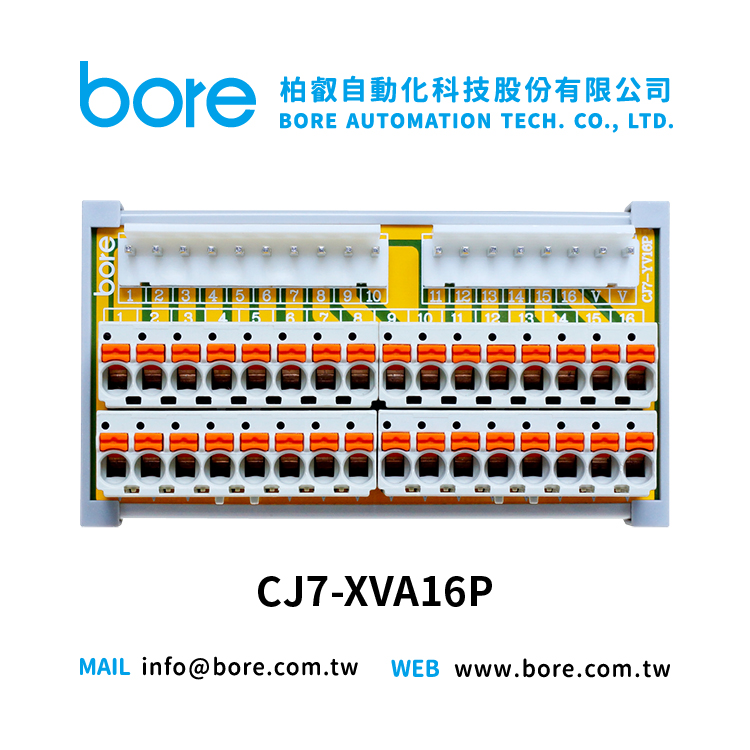

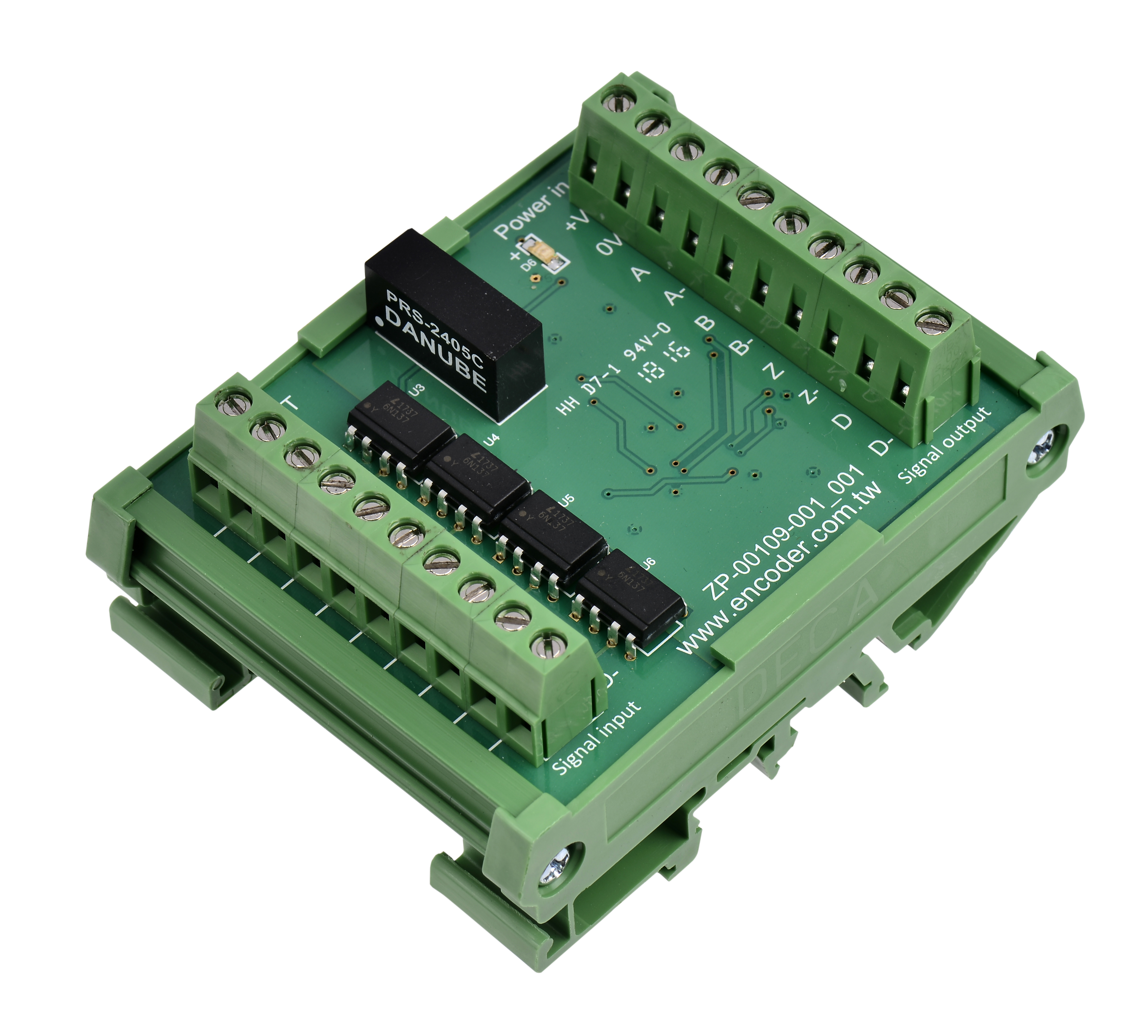

LNC TECHNOLOGY CO., LTD.

Product Description :

‧Pulse or Digital communication type

‧EtherCAT protocol provides high flexibility of peripheral equipment connection control

•High-performance motion control technology

-High-speed and high-precision processing

-Real-time PLC for better accurate and stable control of peripherals

•Applications: Processing center, Tapping machine, Engraving machine, Polishing machine, Double-head milling machine, aluminum profile machine, five-axis milling machine...etc

•Secondary development tools: PLC/Macro/HMI

•Auxiliary function

- File protection function

- Online help function

- G/M code synchronous query function

‧Equipped with LNC smart vibration sensor to provide value-added functions: abnormal vibration detection, broken tool detection…etc.

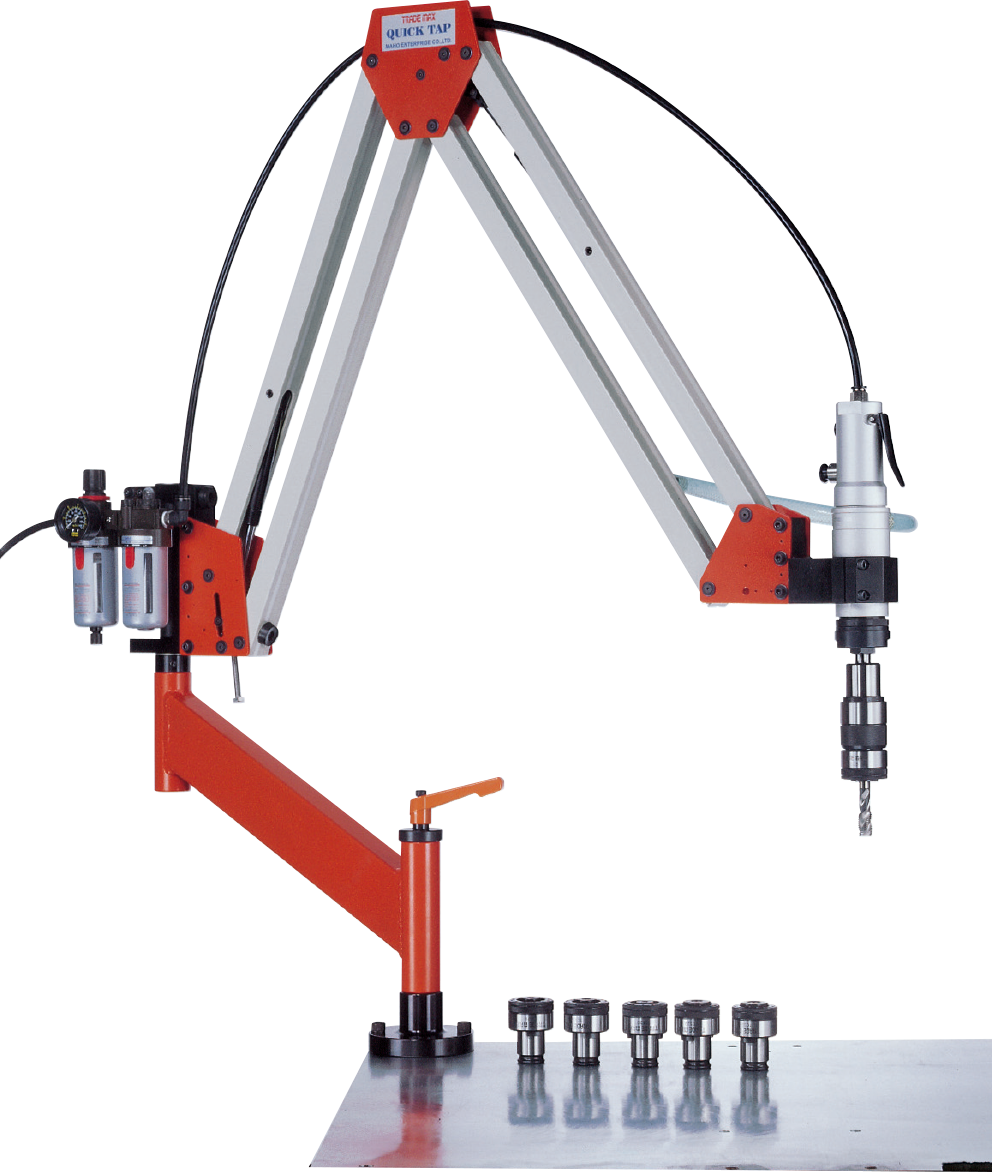

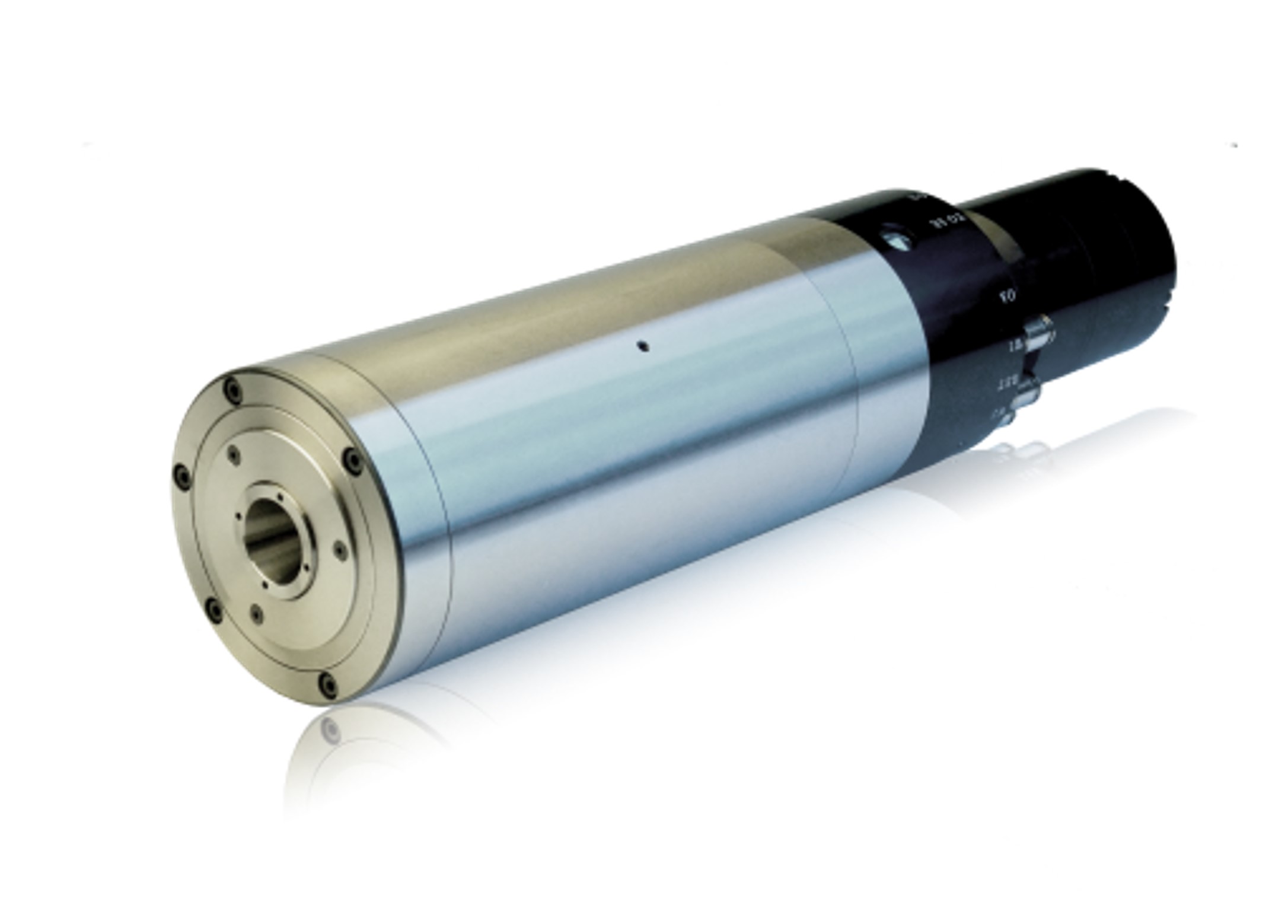

MAHO ENTERPRISE CO., LTD.

Product Description :

Pneumatic tapping machine is suitable for different size taps (from M2 to M27). The arm is equipped with lubricated for life bearings at all swivel points, provides weightless operation through the use of gas counter balance springs and permits the operator to bring the tap to the hole with ease.

HUI-JING ELECTRONIC CO., LTD.

Product Description :

★ WIF transmission control, operating distance up to 35 meters. Provides stable wireless transmission functionality.

★ Band switch supports up to 12 axes.

★ High-performance with options for 2-6 function switches, emergency stop switch, and additional multi-functional switches on both sides, enhancing controllability. CE certified.

★ All components utilize Japanese technology, with the outer casing constructed from high-strength materials for impact resistance.

★ Shielded braided network signal transmission cable for anti-interference.

★ 800mAh lithium battery, optional wireless charging available.

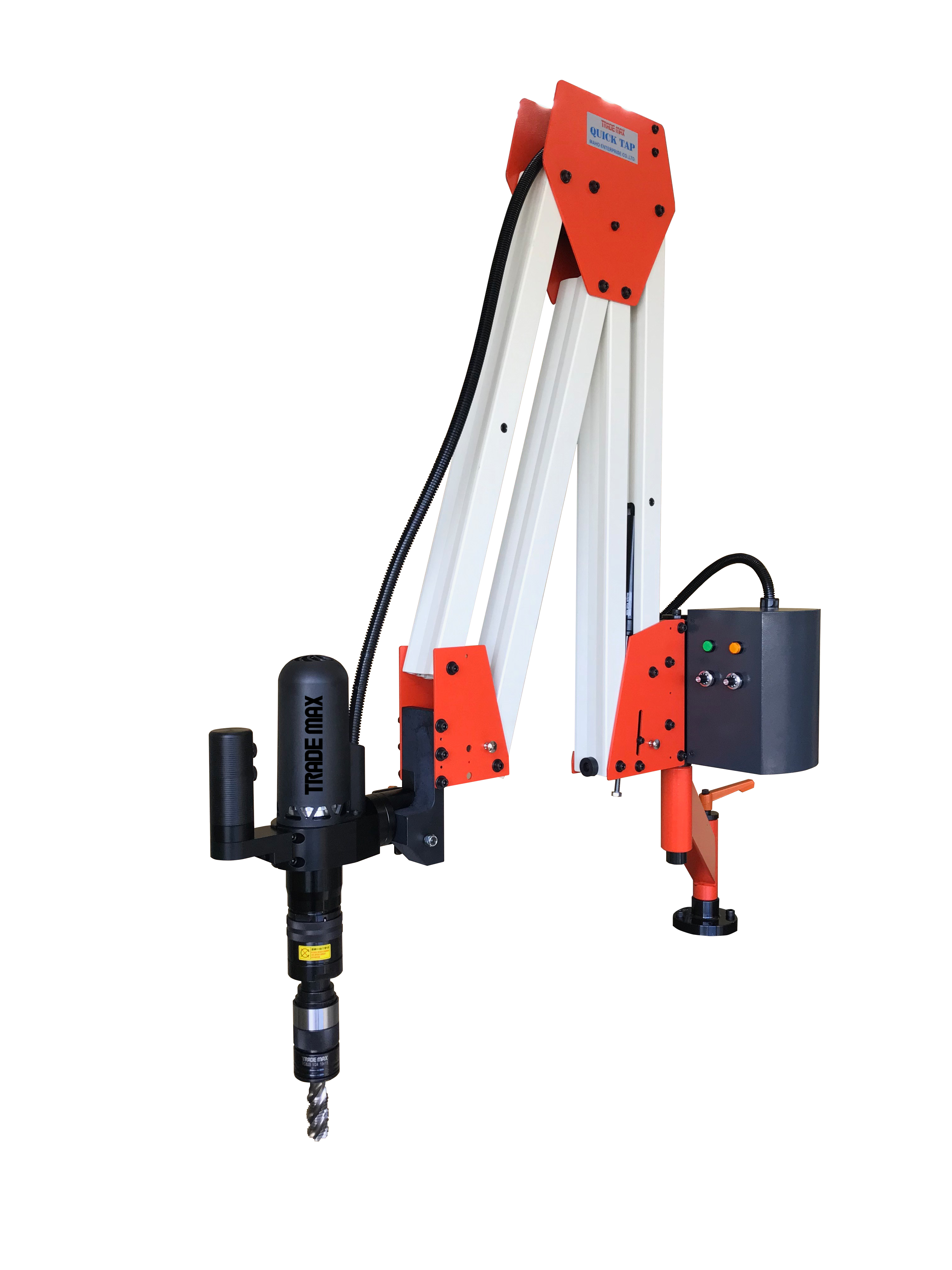

MAHO ENTERPRISE CO., LTD.

Product Description :

Electric tapping machine is suitable for different size taps (from M3 to M24). The machine is equipped with brushless DC motor and driver for controlling the spindle to tap. The arm is equipped with lubricated for life bearings at all swivel points, provides weightless operation through the use of gas counter balance springs and permits the operator to bring the tap to the hole with ease.

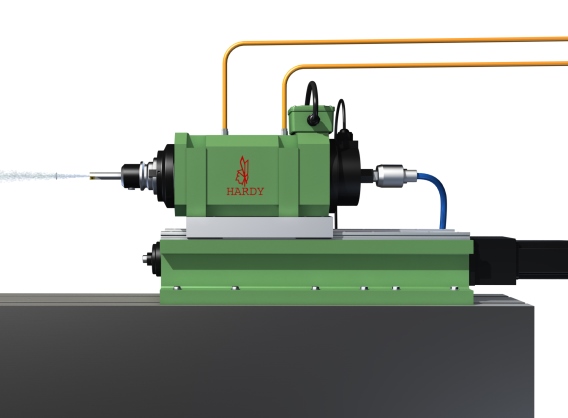

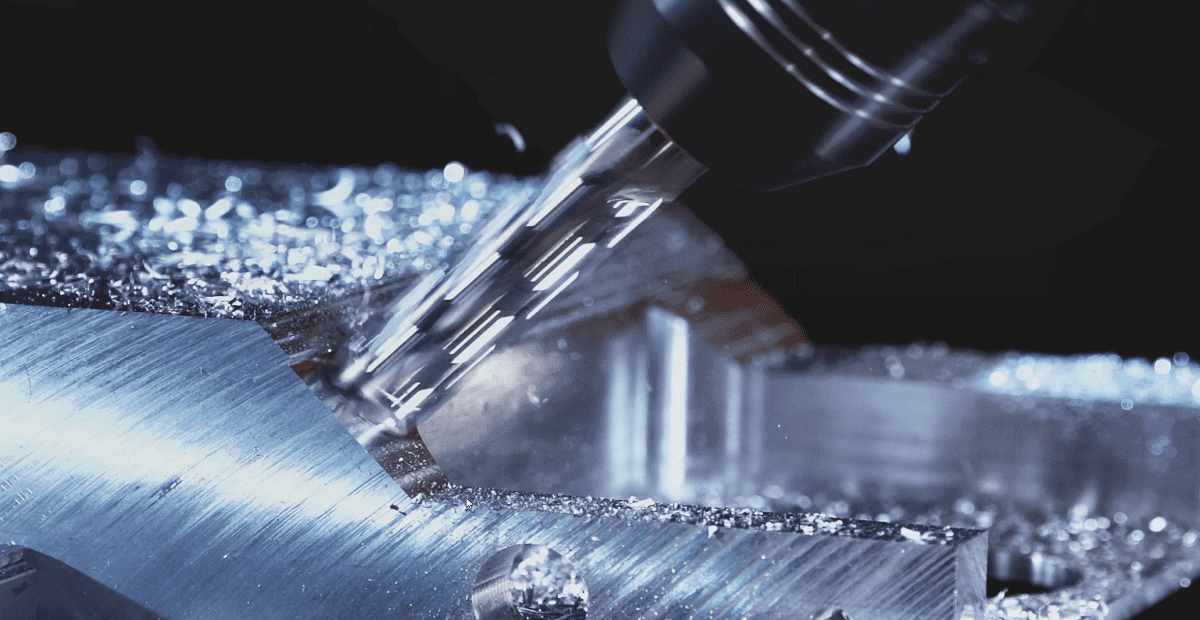

SIEMENS LTD., TAICHUNG BRANCH OFFICE

Product Description :

Optimizing the machining process using real-time data

Machine tool users incur unnecessary costs as a result of tool breakages, unexpected surface quality anomalies, cutting tools being replaced too early, and longer non-productive machining times. Do you know how to avoid these pitfalls and save money by leveraging your real-time cutting data?