Theme

Digital Transformation

Green Transformation

KCW ETERNAL ENTERPRISE CO., LTD.

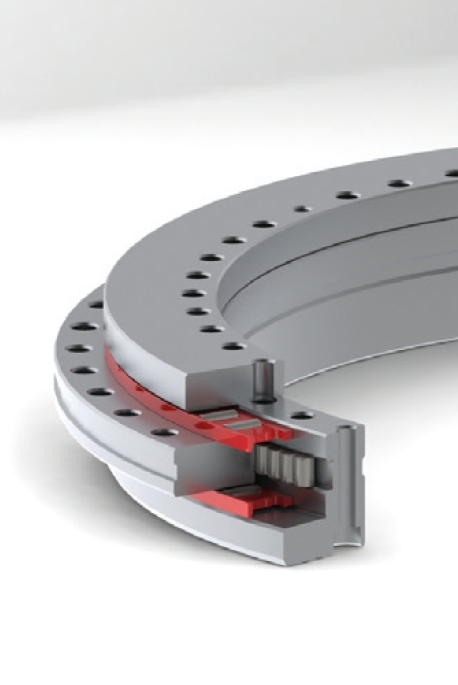

Product Description :

Features: High rigidity, high rotational accuracy, high geometric quality

Compatible with market standard products, short delivery time

The perfect solution for high positioning accuracy requirements:

Rotary tables and indexing plates, integrated processing machines, Milling machines, drilling machines, Machining Center

CHIAH CHYUN MACHINERY CO., LTD.

Product Description :

The CT1-76YM is designed with a combination of double spindle and single turret.

■ ∅76mm enlarged spindle bore is ideal for turning large workpieces. ■ 16-positions power turret with Y-axis, it can complete machining on parts in the main or sub spindle. In addition, tools can be placed facing either the main or sub spindle.

CAMPRO PRECISION MACHINERY CO., LTD.

Product Description :

Campro presents the new NT series CNC lathe which is based on high quality cast iron for perfect stiffness and vibration characteristics. 30° cast iron inclined bed ensures quick chip evacuation. NT-208SM equips BMT Living Turret and C-axis control which enables machine to perform milling functions. Through synchronized control of 8” Main spindle / 6” Sub-spindle to complete the greatest amount of primary and secondary turning possible in one compact platform.

CHIAH CHYUN MACHINERY CO., LTD.

Product Description :

■No matter what operation – turning, milling, drilling, tapping, cutting, side turning and back machining, the

CB series does it all in one operation.

■Sliding head without a guide bush design provide faster setups, lesser remnants, and more cost reduction.

■The CB series provide multiple tooling systems is suitable for versatile cutting applications. On the front side

tooling system, user can set with 4+3 live tools, 6 O.D. tools and 5 I.D. tools. Moreover, on the back milling

system, user can set 4 live tools. The maximum tool speed is 6000 rpm. User can install O.D. and I.D. tools

on the back milling system.

■The sub-spindle head moves on the precision roller type linear ways with extra-large span design for

outstanding stability and positioning accuracy.

CHIAH CHYUN MACHINERY CO., LTD.

Product Description :

SY2-42 Swiss-type CNC Lathe

■ SY2-42E has Ø42mm maximum bar feeding dia. and provide the option to go with or without a guide bush to achieve optimum machining condition.

■ Main spindle tool system can install 6 radial live tools, 3 axial live tools, 6 O.D. tools, 5 I.D. tools.

■ Sub Spindle tool system can install 8 ER-20 live tools, combines with the Y2 linear axis and C2 rotating axis to perform the more complex turning and milling process.

YIDA PRECISION MACHINERY CO., LTD.

Product Description :

The MT-900 has a 5-axis milling head, two turrets, a tool magazine and twin spindles.

The design layout allows for maintaining a large work envelope for both lathe operations-turning and milling.

All six sides of a part can be machined without an operator having to manually resettle the workpiece, so nearly any parts can be machined in an automated manner.

VAST MILLTURN TECHNOLOGIES CO., LTD.

Product Description :

T series turning centers are designed from structure to entire operation flexibility; extreme rigidity provides the best stability for long and large diameter work-pieces. With the various spindle choices, make it possible for the best powerful performance for many types of job.

REN AN INFORMATION TECHNOLOGY CO., LTD.

Product Description :

RenAn's operation simulation workstation is a physical simulation with 3D graphic, showing the cutting and machining process.

[Save consumable cost]: There is no need to worry about the expenditure of consumables, and it will not be affected by pollutants such as waste materials and oil and gas.

[Safety]: Advanced 3D simulation and CNC virtual machine make high risk CNC operation without any danger.

[Smart learning]: Like training the pilot using flight simulators, we use CNC simulator to train the students or operators to be the machinist. Its industrial panel remains the same functionality as real machine that students can practice constantly to accumulate hands-on operation skills.

The controller series of simulator: Fanuc, Siemens, Heidenhain and Mitsubishi.

Turning, Milling, TurnMill, 4 axis, 5 axis.

CAMPRO PRECISION MACHINERY CO., LTD.

Product Description :

Campro spares no effort to develop intelligent manufacturing; fully demonstrating its determination from Industry 3.0 to 4.0, Campro not only has successfully launched CAMPRO IIoT system in line with Industry 4.0 elements in 2016, but also developed its CAMPRO Smart FMS system in 2018. Through flexible manufacturing system, digital control and automated NC program and machine assignment that it can quickly react in case of changes and respond to market demand. In addition, CAMPRO also develops, CAMPRO TOOLING MANAGEMENT SYSTEM, a proprietary system combined with precision tooling/material cabinet to assist customers in managing and analyzing tooling/material usage, 24 hours to get tools or materials and early-warning or alert notifications. In some cases, the fact is increasing automation can improve worker safety and the flexible automation processing is sufficient enough to cope with complex manufacturing processes.