展示テーマ

デジタルトランスフォーメーション

グリーントランスフォーメーション

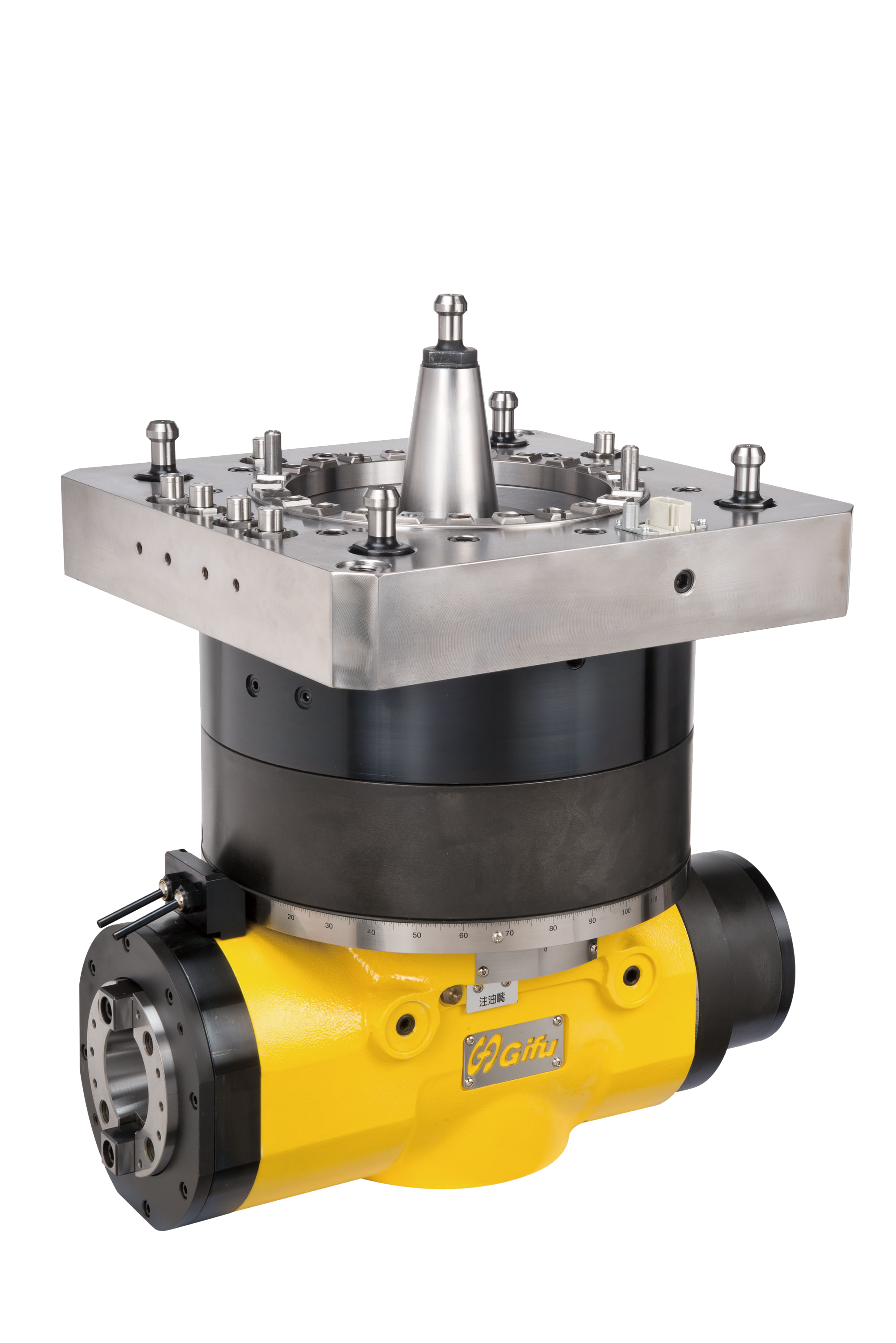

GIFU ENTERPRISE CO., LTD.

製品の説明 :

Model:Semi-Auto 90-degree CTS Milling Head (Maximum Torque:1000N.m) (Maximum RPM:2000r.p.m)

1.The exquisite design helps to reach the purpose at the most limited space.

2.Adopts spiral bevel gear with high rigidity and accuracy to keep reliable running and long life time of the product.

3.High torque transmission and high cutting efficiency.

4. The hydraulic tool pulling design of the spindle makes easy tool loading.

5.The design of extension body is exquisite with solid structure.

6.High accuracy, low vibration and good dynamic rotation accuracy.

7.It can be adopted for CTS system.

GREEN ECO PRO CO. LTD.

製品の説明 :

Precision filtration system

Due to different grinding and processing materials, the particle size, quality, and hardness of the materials to be filtered will also vary. For this reason, our filtering equipment was designed, which can be used for quartz, silicon carbide, semiconductor grinding, electrical discharge machining, or high precision requirements and can effectively intercept fine impurities.

Continuous/batch processing

Customized tungsten steel stirring motor

Filter material saturation alarm

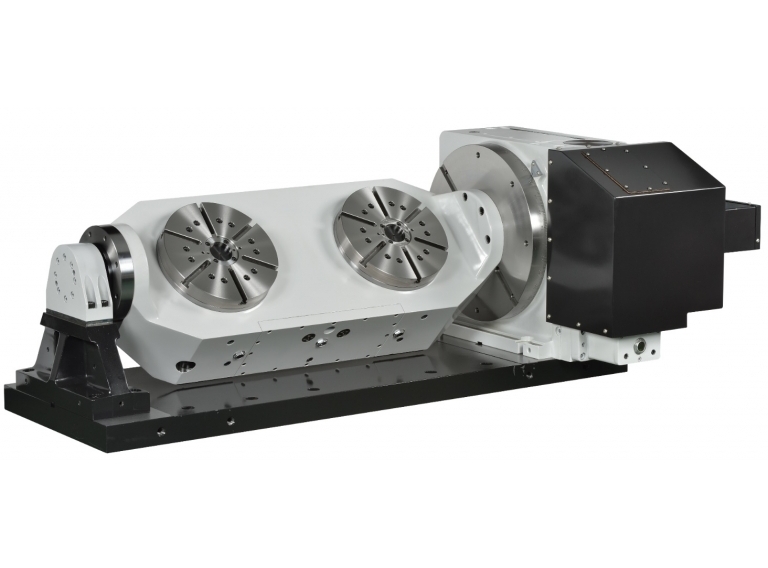

HO CHEN MACHINERY & ELECTRIC IND. CO., LTD.

製品の説明 :

X axis travel:

Single movement: 2550 mm (100") inch

Dual movement: 1275 mm (50") inch

YZ axes travel: 850x600 mm (33"x24") inch

※Y axis can be increased to 1300 mm(51") (Option)

※Z axis can be increased to 1000 mm(39") (Option)

Work table: 3100x1600 mm (122"x63") inch

Max. Workpiece: 4100x2050x1250 mm (161"x81"x49") inch

Max. Workpiece weight: 22000 kg

Max. electrode weight: 500 kg

Machine net weight: 29410 kg

Oil level: 110-1000mm (4"-39") inch

Occupy size(LxWxH): 6480x6600x4600 mm (255"x260"x181") inch

Work Table to platen:

600mm Z travel machine: 1138-1738mm (45"-68")

1000mm Z travel machine: 740-1740mm (29"-69")

Filter: 4

Paper filter:8

Capacity:11300 Liters

Machine Features

> Windows CE controller

> A dialog window with picture description.

> Special repaired frames to quicken the maintenance speed.

> Close-loop design of digital feedback on three axes of the machine significantly increases positioning precision and ORBIT-CUT machining accuracy and efficiency.

> Simple operation interface.

> Common function keys are located on the operational panel for direct use.

> Hot key setting.

> ATC (automatic tool change) and C-axis 360° index can be installed; the process of coarse machining to ultra-fine machining can be completed at one time.

> Dialogue diagram provides various hole-expanding modes such as quick search of edge, centers and datum marks.

> Rich color graphic (the same resolution as a PC screen).

> Automatic multi-step machining (coarse, medium coarse, medium fine, fine, superfine)—up to 10 steps.

> Unlimited number of machining conditions can be saved as machining archives. Each set of machining conditions can be edited, modified or stored. They are easy to edit and easy to find.

> Automatic origin search and multi-point coordinate memory capability.

> 1/2 design capability, ARC automatic discharge waveform detection and automatic adjustment.

> Automatic center position detection, automatic compensation, search of hole center and deepest point; fixed hole machining (cyclic mode, independent mode), which is suitable for different machining conditions; Radial, circular, square, linear (vector), coning, 45° hole-expanding machining.

> Three-axis beeline, two-axis arc, three-axis helix.

> Chinese/English versions interface, metric/British system switch and Z-axis quick up, quick down, slow up and slow down capability.

> Lateral machining, three axes, six directions (plane rotation).

> All alarms describe the source, date and exact time of problem occurrence.

> Optical scale is applied for close-loop position control, enabling extreme position for machining.

> Automatic editing—settings can be done according to type of material, work piece size, machining depth, one side die clearance, final current and rate of electrode wear.

> CNC models possess conventional capability of consistent level of energy discharge, achieving stable and rapid machining and smooth high quality on machining surface while the rate of electrode wear is still low.

> Monitor page indicates machining path and orbital pattern in use.

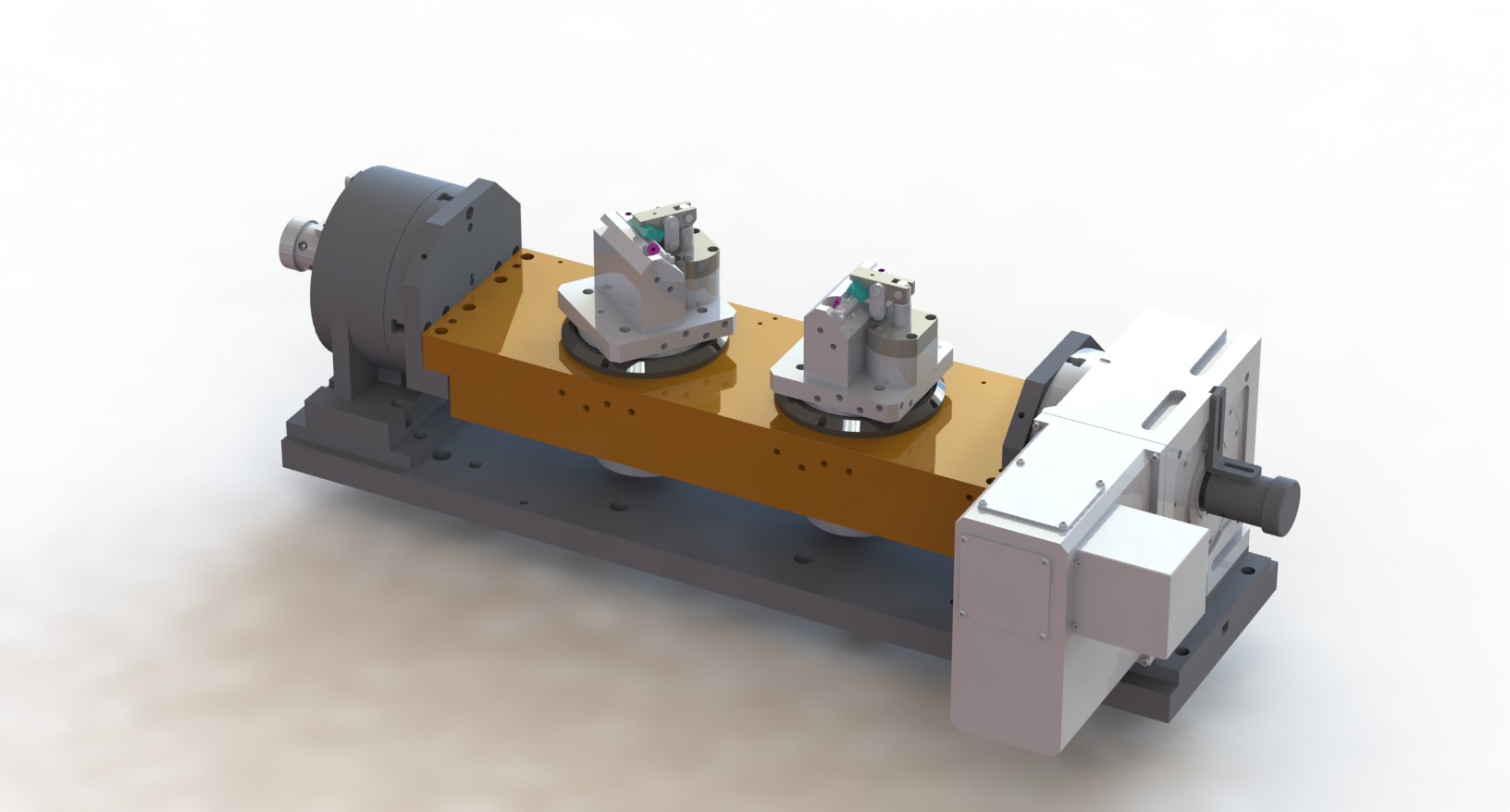

DAH LIH MACHINERY INDUSTRY CO., LTD.

製品の説明 :

龍門型結構,高速加工極穩定。<br />

12,000 / 15,000 rpm高速直結式主軸。<br />

X, Y, Z軸全配置滾柱型線軌。<br />

X, Y, Z軸快速進給率30米/分。<br />

獨創主軸熱補償功能。<br />

立柱結構左右對稱,為最佳熱平衡設計。<br />

X軸獨立於床台上,Y軸獨立於立柱上,無重疊之負荷。<br />

工作台全行程支撐無懸垂,偏移問題,確保最佳加工精度。<br />

三軸滑軌配置線性滑軌,形成穩定順暢,並兼顧高速加工之需求。<br />

衝錘式主軸頭、開頂式護罩。<br />

滾珠螺桿中空冷卻。