展示テーマ

デジタルトランスフォーメーション

グリーントランスフォーメーション

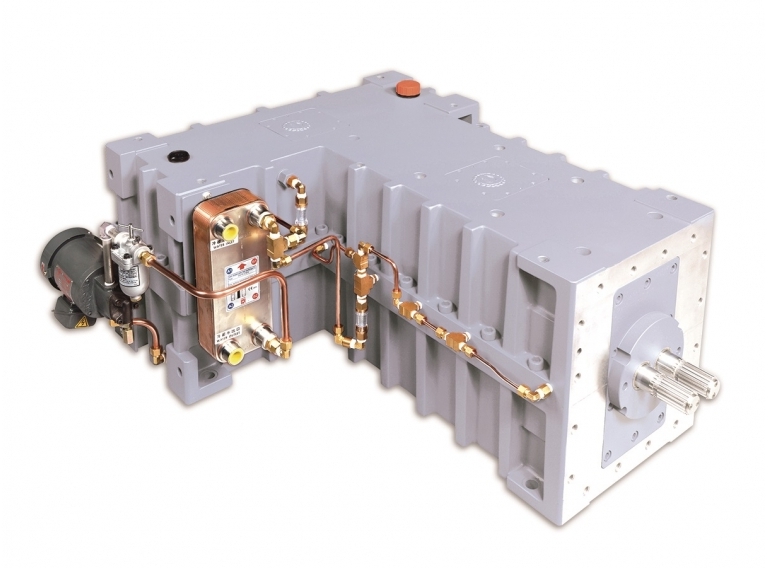

SUN LUNG GEAR WORKS CO., LTD.

製品の説明 :

【SLTW & SLTWH系列】 <br />

因應全球雙螺桿齒輪箱需求日益增加之趨勢,三隆積極研發一系列高效能之雙螺桿齒輪箱滿足其客戶的需求。此系列齒輪箱內建優異的散熱及潤滑系統,確保齒輪箱在高速及高扭力運轉時,能展現穩定及優異的輸出效能。齒輪箱內部並組配精準的齒輪及雙軸間距,搭配高品質串列式精密軸承,提供給全球客戶最先進品質且最佳輸出效率的產品與售後服務。

DETRON MACHINE CO., LTD.

製品の説明 :

轉速超過250min-1以上,高速定位適用於高產量定位加工。<br />

<br />

無間接傳動機構,降低整體慣量,提高加速性。<br />

<br />

搭配高精度編碼器可達到高精密定位。<br />

<br />

無間隙傳動,改善工作精度及表面粗糙度。<br />

<br />

直接驅動實現零磨耗。

G-TECH INSTRUMENTS INC.

製品の説明 :

The performance of the spindle is an important key to processing quality. When you understand the performance of the spindle, you can predict and control the quality of the processed parts. The shape accuracy, roundness, and surface roughness of the workpieces are all related to the performance of the spindle. Only when the spindle is real measuring the accuracy of the spindle at the processing speed of the machine has meaning to the control of the quality of the processed parts, so measuring and understanding the performance of the machine tool, finding the best working speed, determining the warm-up time, even confirm the accuracy of the spindle after the collision.

LION provided this SEA analysis system as early as 1993 to help spindle manufacturers, machine tool factories and processing plants to reduce workpiece defect rate and improve product quality.

★The SEA system complies with the following international standards:

✓ ANSI / ASME B5.54-2005: "Methods for Performance Evaluation of CNC Machining Centers"

✓ ISO230: Test Code for Machine Tools, 3: "Determination of Thermal Effects" 7: "Geometric Accuracy of Axes of Rotation"

✓ ANSI / ASME B5.57-1998: "Methods for Performance Evaluation of CNC Turning Centers"

✓ ANSI / ASME B89.3.4: "Axes of Rotation, Methods for Specifying and Testing"

Tim Growing Bearing Co.,Ltd.

製品の説明 :

More load capacity , so TIMG's bearing can be covered both high-speed cutting and heavy cutting ; not only satisfy the demand of heavy cutting , but also realize the lower temperature rise under the conditions of limited speed.

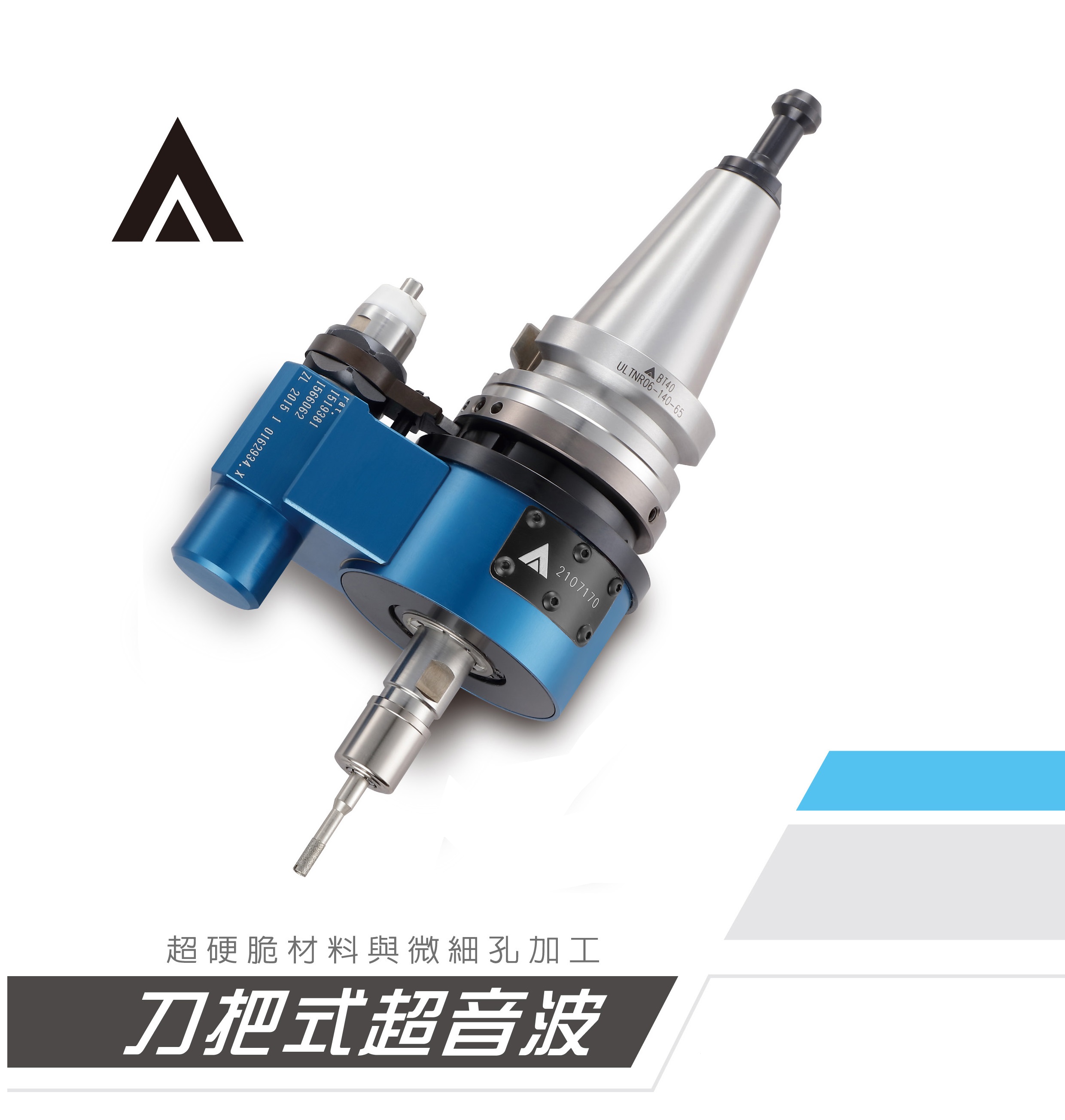

ACROW MACHINERY MFG. CO., LTD.

製品の説明 :

For Hard brittle material and micro holing drilling / Toolholder support for coolant function /

Clamping accuracy under 5 micro with the spring collets/ No need for special machine /

Easy to operate and install /

Reducing cutting resistance /

Improve surface roughness

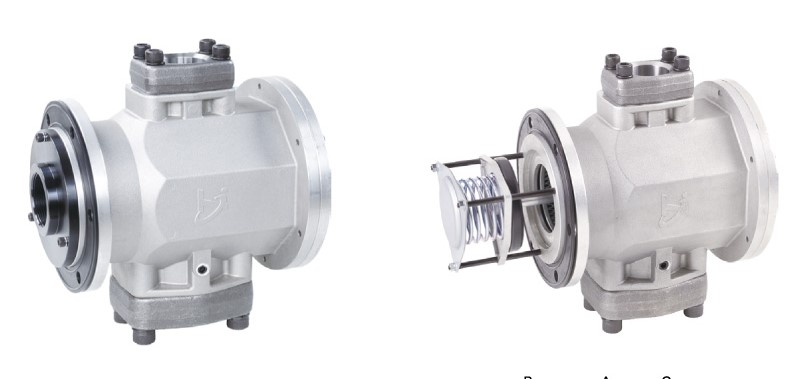

CHUAN TAI HYDRAULIC MACHINERY CO., LTD.

製品の説明 :

In order to solve the problem of difficult cleaning, the market developed so-called box-shaped filters, but still can not completely solve

1 takes up too much space

2 Multiple pump combination systems must be configured one-to-one, resulting in too many connectorsProne to oil leakage

In order to solve the above problems, the company has developed a pair of two-box external magnetic flange filters to reduce space and prevent oil leakage problems, reduce assembly time and parts costs

HERBERT ENTERPRISE CO., LTD.

製品の説明 :

1.Modelling

The main structure could do universal machining with soft or hard jaws without any limit of angle.

2.Function

The universal vise is suitable for milling, lathe, and CNC machining center especially for 5-axis CNC machining center with 200-1000cm machining table and 12000 rpm. The swivel base can move in two-way to find the center point, easy and efficient to meet customer’s requi-rement.Can be mounted to CNC machining center to rotate the work-piece via swivel base for processing.

3.Quality

With the heat treatment alloy steel, it’s hardness reach 50-60 degree with high durable quality. The parallelism accuracy reaches to 0.01mm. The main body can support the sliding base increase its stability.

4.Innovative

HERBERT TMV successfully conveys the spirit of HERBERT - reliable, stable, innovative and professional.

JIN TAIRY ELECTRIC CO., LTD.

製品の説明 :

JPS Technical Specifications

• Input voltage regulation range: rated voltage±15%

• Output efficiency: more than 95%

• Output stability rate: rated voltage±1%

• Waveform distortion: No distortion (compared with input waveform)

• Overload capacity: Above 150% of the rated output current

• Working environment: -0C~+40C

• Induction time: less than 0.1 seconds (less than 5 weeks)

• Working humidity: 95%

JPS Features

• Intelligent logic voltage regulation method

• Self-detection function

• LED indicator on the panel

• Patented bypass device included

• Large-range over-high and low-voltage protection device

• Under-phase instantaneous power failure short-circuit protection device

• Prevent activation of over-voltage device (SOVP)

Electronic double circuit panel design

• The internal panel voltage can monitor the three-phase voltage

• The DIP switch function is easy to set up

• Separated voltage stabilization design, three-phase unbalanced 100%

• Taiwan Patent No. 60215 62577

• Mainland Patent No. 12559 5390066

MANFORD MACHINERY CO., LTD.

製品の説明 :

VX-600 5-Axis Machining Center is designed for multiaxes machining of small and large series of complex 5-side workpieces. With swiveling head and rotary table, VX-series is able to do simultaneous 5 axes machining with high accuracy.

High proformance swiveling head, tilting angle from -120 ~ +30 equipped with 15,000rpm built-in spindle.

VX-600/VX-600T is with an enbedded Ø 630mm diameter rotary table. Any complex workpiece can be accomplished with a single setup.

Ametek Taiwan Corp., Ltd.

製品の説明 :

PGI NOVUS: Fully automatic, ultra-high precision measuring system for surface finish, contour, 3D and diameter.

FTS LASER:Surface finish and contour instrument of high precision & large range.

i-Series PRO:High resolution surface finish and contour instrument for precision machining.

Intra & Surtronic Roughness:High precision surface finish and contour instrument for workshop and quality inspection room measuring & Super durable portable roughness testers.

HEIDENHAIN CO., LTD. (TAIWAN)

製品の説明 :

Linear encoders are indispensable for machines with high demands regarding positioning accuracy and machining speed. Linear encoders directly and immediately measure the actual position of the feed axis. This makes it possible to eliminate a number of potential error sources: Positioning error due to thermal behavior of the recirculating ball screw

, Reversal error, errors due to deformation of the drive mechanics by machining forces, kinematic errors through pitch error in the recirculating ball screw.