展示テーマ

デジタルトランスフォーメーション

グリーントランスフォーメーション

TONGTAI MACHINE & TOOL CO., LTD.

製品の説明 :

‧The VP-12 combines the advantage of a smaller footprint with a large internal machining space, equipped with a high-speed spindle to meet the requirements of efficient and precise machining.

‧Direct-drive spindle BBT-40 provides a high rigidity and high efficiency.

‧The tool magazine allows for flexible tool placement and pre-selection, coupled with a high-speed ATC mechanism to reduce non-cutting time, showcasing efficiency similar to drilling and tapping machining centers.

‧High quality spindle and high rigidity structure design subject to high standards of machine accuracy to achieve good cutting performance.

‧By Tongtai production system, we check every detail process from design, manufacturing, assembly and QC.

ROYAL PRECISION TOOLS CORPORATION

製品の説明 :

▶High dynamic rotary accuracy

▶High precision, low vibration

▶Same flange dimension, high adaptability

▶Applications: Milling, mill-turn, tapping, grinding

LIS AUTOMATIC CONTROLLED CO., LTD.

製品の説明 :

The PJ-30VT is a frequency control (variable volume) complex system. Supplied for maximum 70bar (1000psi), 100bar (1500psi) or 140bar (2000psi) working pressure to Swiss Lathes, CNC Lathes, and Machining Center. This system carries the LIS Automatic patent high-performance centrifugal filtration device, extended the lifetime of the consumables, and also lets the system more stable. Designed for the restricted tank capacity machine, reduced the problems of the tank foaming and overheat effectively.

Giant Red-Wood Int’l & Co. Ltd

製品の説明 :

RW-600A Hydraulic Riveting Machine (Mitsubishi 10” HMI)

(Without Feeding System)

-Safety Device to protect finger get injured

-Proportional Value Control System

-Double-Pumps hydraulic Designed

-Auto-Riveted Counting to avoid missing riveted

-Mitsubishi 10” HMI

-Control System: Mitsubishi PLC

-Pressure Range:2-53KN(6T)

-Horsepower:3HP

-C type throat depth:450mm

-C types throat height:400mm

-Power Voltage:220V Three-Phase

*Mitsubishi 10” HMI can ensure the pressure during the operation. It also can auto-check for faulty.

*Suitable Rivet:Nut up to M10, Bolt up to M8, FH Screw up to M6 (Carbon Steel)

* Proportional Value Control System: Specific Pressure adjust bottom designed, can adjust correctly pressure within 10 second, precision within+/-1%.

*Positive Stop System: Designed for soft working pieces to ensure the flat surface. Thickness accuracy up to +/-0.05mm

*OMRON 5” HMI can ensure the pressure during the operation. It also can auto-check faulty.

*Suitable Rivet:Nut up to M10, Bolt up to M8, FH Screw up to M6( Carbon Steel)

*Pressure control easy to operate: Specific Pressure adjust bottom designed, can adjust correctly pressure within 10 second, precision within+/-1%.

*Positive Stop System: Designed for soft working pieces to ensure the flat surface. Thickness accuracy up to +/-0.05mm

REAL TERN INDUSTRIAL CO., LTD.

製品の説明 :

The plate heat exchanger gives an excellent heat exchange capability. It replaces traditional evaporator and condenser. It is utilized in industries such as freezer and industrial controlling. The plate heat exchanger is small at size, light at weight and less power consumption.

Taiwan Auto-Design Co.

製品の説明 :

// SolidMEN-300的優點

✅ 材料: 不綁材料僅建議合格廠商,未來可自行選用適合材料

✨ 雷射: 德國 500W 水冷式雷射穩定性佳

⚡ 層厚: 層厚可控範圍 10~100μm (最小進給單位 10μm)

🛠️ 成品: 可列印多種金屬材料,強度超過鑄造,可作為表面後處理及拋光使用

🔬 研發: 不綁參數開放製程研究,未來材料無受限可自行開發

⬆️ 尺寸: 300x300x300 可製作大尺寸工件,另有機型可增大或縮小

💎 緻密度>99.5%,品質優於鑄造,近似鍛造

🤖 搭配遠端資訊與智能化視覺模組,方便製程穩定性及智慧化整合。

(即時錄影、列印層數/高度、雷射功率、粉未剩餘量、腔體含氧量、製程時間等)

AUTOGRIP MACHINERY CO., LTD.

製品の説明 :

◎ Second Collet Changes Slash Setup Times.

◎ Industry-Leading Gripping Range.

◎ Ultra-Precision Accuracy.

◎ Parallel clamping over the entire clamping length

◎ Extreme Grip Force = Most Aggressive Chip Removal/Fastest Cycle Times.

◎ Maximum Rigidity Produces Superior Part Finishes.

◎ Best Tool Clearance - Critical For Live Tooling.

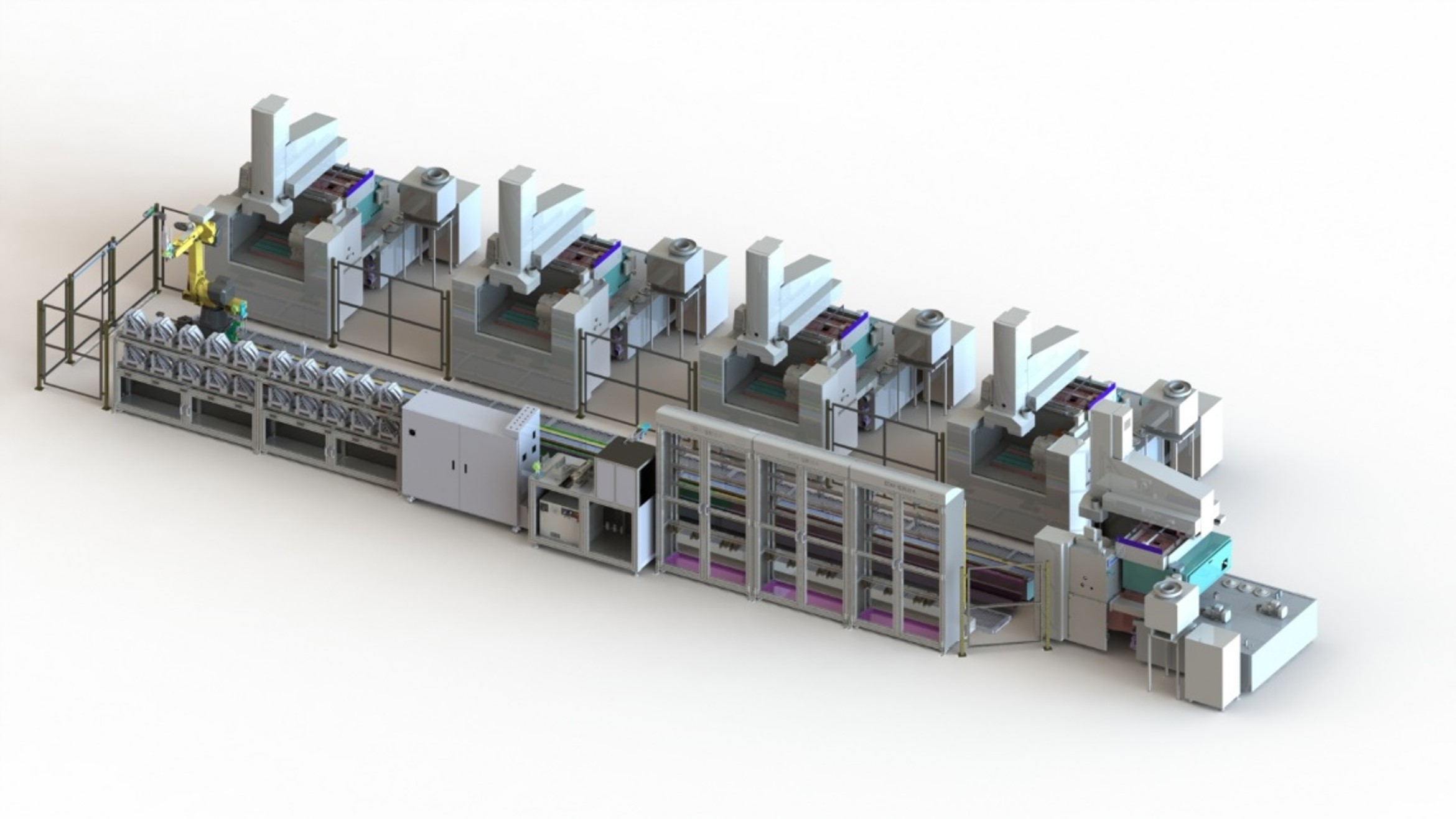

OSCAR E.D.M. COMPANY LTD.

製品の説明 :

Quick Integration

EX/EXD Series electrical discharge

machine, capable of easy integrated with

MES system, online measurement,

storage system and etc via OPCUA, API.

Smart Production line

Actual application on automobile moulding industry in

Europe. EX series sinker EDM integrated with MES and

milling machine where perform the production just-intime

without any interruption. By increasing 30% of

overall equipment effectivenss (OEE), 2 EDM will then

bring out extra 3,000 hours working time per year

RAISE PRECISION CO., LTD.

製品の説明 :

The compact, high-resolution MiniCODERs have proven their value for speed and position acquisition in highly dynamic applications. They use their full potential when installation situations with little space require a particularly compact, robust and reliable measuring system. The magnetic measuring systems consist of a ferromagnetic target wheel and a scanning unit. Without dedicated bearings, they are completely wear-free and maintenance-free. The optimised circuit and screening technique, and fully encapsulated electronics ensure reliable operation even in harsh environments.

BUFFALO MACHINERY CO., LTD.

製品の説明 :

AXILE’s automated G6 Robotic Pallet Changer (RPC) solution features a 2-axis robot that keeps machines supplied with workpieces 24/7 from the back side of the machine. Part processing continues simultaneously within the machining center while operators deal with workpieces at the holding area at the back, significantly raising production efficiency to boost throughput.

The G6 RPC solution caters to diverse production requirements, with multiple options available based on workpiece specifications:

8 pallets (workpiece max. size 500 x 305 mm; max. weight 220 kg)

10 pallets (workpiece max. size 400 x 305 mm; max. weight 220 kg)

16 pallets (workpiece max. size 230 X 305 mm; max. weight 98 kg)

20 pallets (workpiece max. size 160 x 250 mm; max. weight 30 kg)

With AXILE’s digitalized intelligent automation solutions, manufacturers can eliminate production bottlenecks and ramp up production.

TAIWAN FANUC CORPORATION

製品の説明 :

In the current era of high personnel costs. Are you also considering importing automation, but you are worried that the technical threshold is too high and you will not be able to operate it!

Through FANUC QSSR, you can quickly connect with the robot, and use the familiar CNC operation interface to directly operate the robot, simplify the time of getting started with the robot, and quickly introduce automated production.