展示テーマ

デジタルトランスフォーメーション

グリーントランスフォーメーション

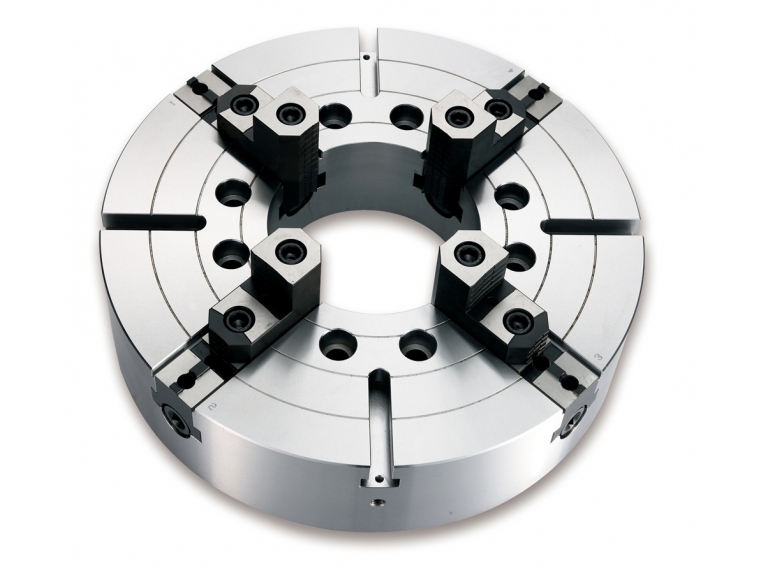

YANMECH Industrial Co., Ltd.

製品の説明 :

【J Series:】

1. Adapter Plates can be selected.

2. Install side strips and chips cover sealed base jaw to prevent chips and coolant ingress.

3. The jaw can be individually operated, and irregularly shaped workpieces can be clamped.

4. Special specifications can be customized.

【L Series:】

1. Adapter Plates can be selected.

2. The jaw can be individually operated, and irregularly shaped workpieces can be clamped.

3. Special specifications can be customized.

GRINTIMATE PRECISION INDUSTRY CO., LTD.

製品の説明 :

a.Equipped with the exclusive hydrostatic spindle.

b.Equipped with the exclusive hydrostatic guideway .

c.The grinding wheel can be widened to 300mm with one-feeding grinding.

d.Headstock and tailstock both work with double sided synchronous.

e.Our products are on hundred percent designed and manufactured in Taiwan. To guarantee the stability of machine, all of the cast components go through a pressure relieve process

Administration for Digital Industries, moda

製品の説明 :

In order to decrease probability of the work safety accident, occupational disaster lost and casualties. We are focus on staff, machine, materials, environment in the process. We used AI, IOT and cloud service to develop an intellgent and automatic manage method. Through the AI to predict environmental hazards, confirm the people equiment, guardianship and machine position...et.al function to achieve work safety, quality, warning and smart progress management. It promote the manage efficiency, decrease the cost of manage and occupational disaster happening in the same time.

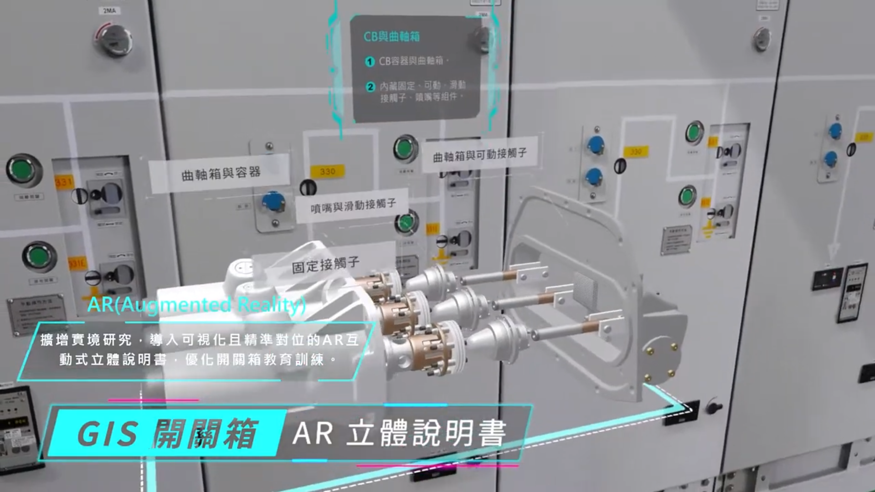

Administration for Digital Industries, moda

製品の説明 :

The Industrial XR SOP Solution""utilizes AR/VR/MR cross-platform integration technology to ensure seamless operation across various devices such as smartphones and head-mounted displays. It is specifically designed for the industrial sector as an XR intelligent carbon reduction integration platform service.

It's key features include support for ""cross-temporal"" information transmission and real-time monitoring, enabling precise and instant ""cross-span"" collaboration capabilities. Through the integration of virtual and augmented reality, information is transformed into a ""visualized"" presentation, allowing users to intuitively understand and operate, thereby assisting enterprises in effective resource management, reducing waste, and helping industrial production lines lower carbon footprints. This, in turn, improves energy efficiency and achieves a more environmentally friendly production model.

The application scope covers various stages of industrial production, including machine equipment, factory premises, vocational training, remote collaboration, maintenance and operation, and business showcases. Through comprehensive cross-platform integration technology, it provides intelligent, efficient, and eco-friendly solutions.

JEFFER MACHINERY CO., LTD.

製品の説明 :

This machine comes in a one-piece construction that has been heat-treated to achieve maximum rigidity. The rails are thermal treated and precisely ground to reach hardness of more than HRC 60˚. Furthermore, options are available to adopt rails of various lengths to meet different knife grinding requirements. The machine length can be customized for specific needs from 1,600 to 4,000mm. Rough and finish grinding wheels can be controlled manually and automatically. The minimum grinding wheel downfeed amount is 0.005mm and the spindle is equipped with an automatic cooling system which ensures excellent cooling effect. The SSG-8 employs an automatic lubrication system for smoother operation and longer service life.

SSG-8 Feature :

1. Knife tools movement type.

2. After grinding by coarse wheel and fine wheel, knife

tools can be sharp.

3. Force cooling system on motor shaft obtains better

cooling effect for the knives.

4. Grinding wheel lifting seat is used by ball bearing screw,

it can adjust up and down movement in precision.

5. Water splash guard and coolant tank are made of

stainless steel.

6. Grinding Capacity (Magnetic Chuck) LxW :

2500x200mm

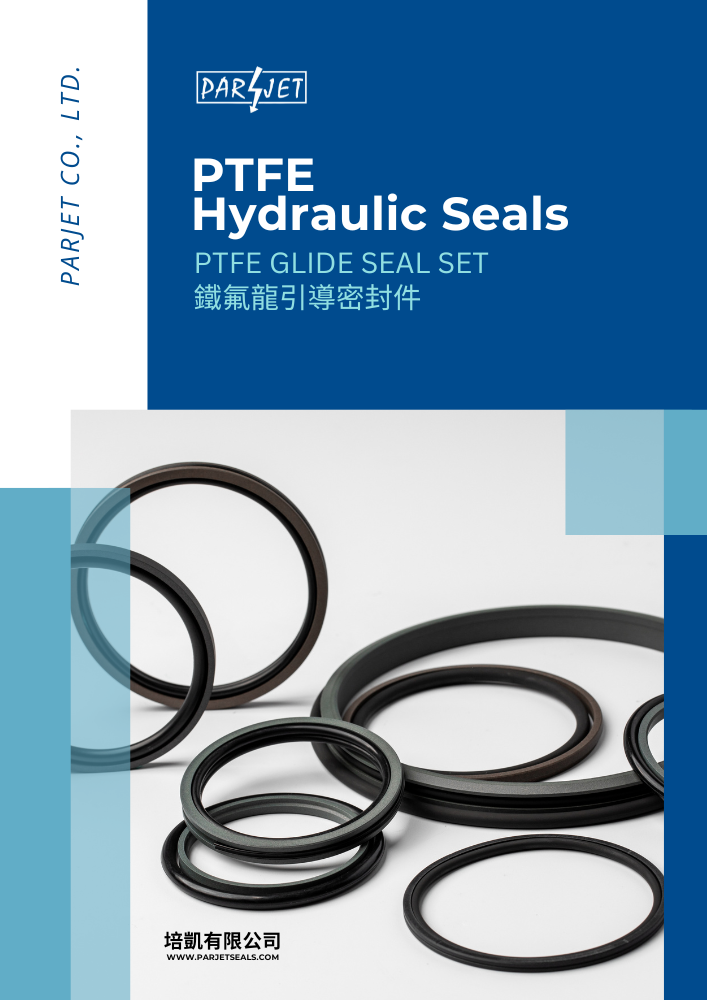

Parjet Co.,Ltd.

製品の説明 :

PTFE Glide seal sets consists of a PTFE sealing element with a rubber O-ring functioning as elastic energizer. This type of Teflon seal is mainly used to seal reciprocating rods, pistons, and plungers, commonly found in hydraulic and pneumatic applications. The required sealing effect is achieved by radial pressure, produced by the preloaded element and system pressure, on the lip against mating surface. The elastic energizer pushes the PTFE ring against the mating surface which provides the initial sealing force for the PTFE seal.

SGCAM TECHNOLOGY CO., LTD.

製品の説明 :

主功能介紹:<br />

全中文畫面,易學、易懂、易用,為加工業最適合的加工軟體,操作軟體完全不用背指令。<br />

可由AutoCAD製圖畫出工件外形,再匯入DXF、IGS圖檔,轉換為CNC程式碼。<br />

不必畫3D圖形,一條輪廓線和一條路徑線一般2D圖即可輕鬆轉出車銑的加工程式。<br />

快速C軸填充式的輸入方式 ,很簡單的方式就能轉出C軸加工程式。<br />

參數式的C軸工法操作條件更改G碼自動跟著改變。<br />

製作程式時車銑工法可依加工順序任意作排序調整。<br />

3D實體切削模擬預覽,可避免干涉及過切事件發生。<br />

主軸和副主軸的獨動或同動會自動等待(指定機型) 。<br />

同一個程式中可同時指定不同的切削計算方式有走刀式、走心式、櫛式。<br />

車銑的刀具庫參數可依實際機台型號的刀具位置做個別指定。<br />

可在端面、圓弧面、橢圓面上做刻字。<br />

支援單筆劃字型刻字。<br />

系統支援:<br />

支援廠牌有Citizen 、Star、Miyano、Tsugami、洽群、縉錩、利高、精機、瀧澤、程泰、寶麗金…<br />

支援側銑側鑽等循環加工指令G87、G88、G184<br />

支援極座標G12.1 、G13.1、 G112 、G113<br />

支援圓筒補間G07.1、G107

REN AN INFORMATION TECHNOLOGY CO., LTD.

製品の説明 :

Just like the real CNC machine, equipped with exactly same overall appearance, actual handwheel and real machine operation panel as numerical control machine.

Solving the difficulties of real machine: precise, complicated and very expensive.

With CNC Simulator, everyone can learn CNC machine operation and accumulate hands-on operation skills.

CNC training machine is equipped with exactly same overall appearance, actual handwheel and real machine

operation panel as numerical control machine. Its purpose is to train students for accumulating CNC machine operation skills (program transmission, programming, tool selection, tool compensation and alarm clear )

Overall design is more attractive, and it emphasizes on interaction to make students less mistakes happened.

Not only decreasing learning cost but also letting students work and learn in the safe environment.