展示テーマ

デジタルトランスフォーメーション

グリーントランスフォーメーション

NINE-9 CUTTING TOOLS CO., LTD.

製品の説明 :

Nine9 chamfer mill is designed for chamfering and countersinking with an indexable insert.

The insert is a specifically designed for use in high speed machining ; the multiple flutes

provide for increased feed rate, optimizing performance and reducing cutting time.

High performance chamfer tool for upgrading your machining process.

For front and back chamfering. Eliminates 2nd operation or deburring time.

● Excellent Repeatability

• Smallest Indexable counter sink, diameter ø7 mm.

• The insert is dual-relief angle, specially edge honning and optimized coated for high cutting speed.

• Optimized the number of teeth on the holder to achieve higher feed rate.

● Economical

• Each insert has 4 cutting edges.

• Long tool life.

● Applications

• For front and back chamfering.

• 90° counter sink and 45° chamfering.

• For counter sink, circular chamfering, contour chamfering and face milling.

BRIGHT JING CHIN MACHINERY CO., LTD.

製品の説明 :

精勤精機有限公司為一家專業的CNC精密機械零組件設計與製造供應廠商,目前主要產品為:<br />

1. 聯軸器<br />

- SCD 主軸迫緊環形式 / FCD進給軸側邊鎖固式 / 客製化聯軸器<br />

2. 主軸夾爪:提供各式主軸用夾爪,規格如下<br />

- BT type<br />

- DIN type<br />

- CAT type<br />

- OTT type<br />

- HSK type<br />

- ISO type<br />

- 倍力夾爪<br />

3. 快速接頭:提供油氣水的快速結合元件。<br />

4. 拉桿組:提供客製化主軸拉桿組設計與製造。<br />

5. TPI精密軸承:提供TPI專業軸承相關服務。<br />

Taiwan Machine Tool & Accessory Builders’ Association

製品の説明 :

TMBA's members can join below 10 committees by their interest:

1. Machining Center Issue committee.

2. Turning Center Issue committee.

3. Forming Machine Tool Issue committee.

4. Non-traditional Machine Tools(EDM, Laser,…,etc) Issue committee.

5. Multi-Tasking(/Integrated) Machine Tool Issue committee.

6. Grinding Machine Tool Issue committee.

7. Functional components Issue committee.

8. Raw Material and Processing Issue committee.

9. Transmission component Issue committee.

10. Accessories & Hardware Issue committee.

FINTEK INDUSTRY COMPANY LIMITED

製品の説明 :

Initial pinch 3-Roll plate bending machine

Affordable single pinch bending application, flexible use of small space workshop

3 rolls camber designed with hardness HRC 50-53 degrees, dealing with various material processing

Build in high quality hydraulic system with overload protection

The first choice for petty workshops or personal studio, small invest and fast get back

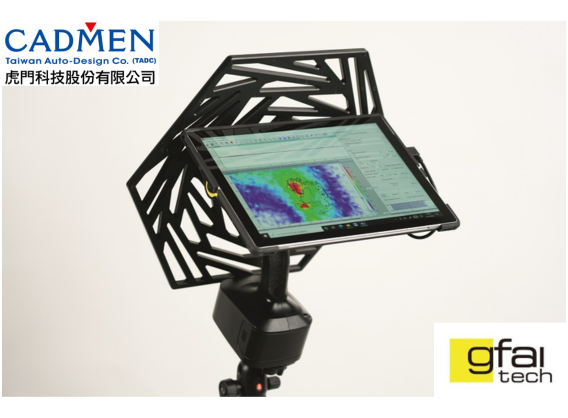

Taiwan Auto-Design Co.

製品の説明 :

德國 Gfai tech 是量測設備的領導者,長期專注於聲音與振動的量測設備開發並提供可視化產品與服務。其結構動態 (Structure Dynamics) 應用產品,確保客戶從聲音與振動結合的量測數據中獲得更多知識用於解決工程問題。

Key Benefits

► Gfai Tech/ Mikado 是解決噪音與振動問題的完善解決方案

► 觸碰螢幕與手動觸發按鈕等特性確保快速與簡單操作

► Mikado系統包含快速及有效聲學量測與分析所需的所有組件

► 可透過設備直接記錄數據與進行基於頻域與時域的基本分析

► 全移動裝置使得幾乎可從任何位置進行量測

► 系統陣列帶有整合的Intel® RealSense™ 超高畫質(Full HD)解析度景深攝影機與記錄深度訊息能力

FALCON MACHINE TOOLS CO., LTD.

製品の説明 :

Chevalier’s FSG-ADIV Series of surface grinders have several design features to shorten your processing and non-processing preparation while delivering high-precision workpieces year after year—functions you might not expect on such affordable machines: iSurface control, variable speed spindle, constant surface speed, loading detection and in-machine manual dynamic balancing.

FSG-ADIV Series grinders also feature tools to secure Big Data with Chevalier’s exclusive iMachine Communications System TM (iMCS).

This software package, combined with data analysis, enhances machine efficiency in the factory while enabling remote monitoring and diagnostics to track machine performance and identify potential problems before they begin.

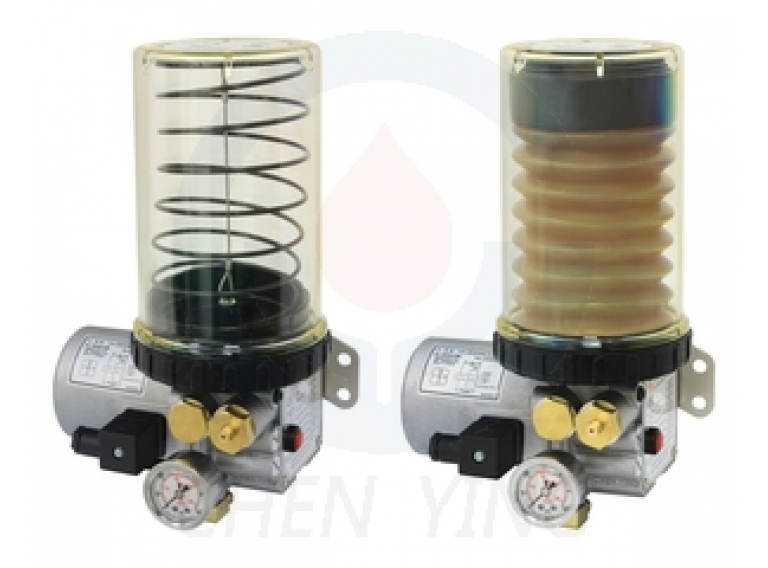

CHANGHUA CHEN YING OIL MACHINE CO., LTD.

製品の説明 :

1. KGC and KGCP types are suitable for grease NLGI grades 000, 00 and 0.

2. Recommend using a grease gun for filling with lubricant from grease inlet. It can avoid air or impurities dropping into the reservoir.

3. KGC and KGCP types are controlled by PLC (Programmable Logic Controller). It can work with CV type Progressive Feeders which can supply fixed volume of grease. CV type Progressive Feeders can assure each of lubrication point has equal amount of grease.

4. Pressure switch can be added on request for checking if the piping works normally. The standard setting is at 60 bars and the standard specification is NC (Normally Closed) contact, which means if the pressure doesn't reach the default setting, it sends continuous signals. NO (Normally Open) contact is available on request.

5. Magnet Level Switch is also an optional accessory that can be added upon request. It sends continuous signal automatically when the grease level is lower than the minimum level.

6. For the first time use, slightly press the Feed button (F button) to feed grease immediately. F button can be used as manually grease feeding for no more than 3 minutes.

7. AC110V and AC220V motors have thermal controls. When the motor temperature reaches 100℃, the sensor will be on to stop the motor continue running about 5 minutes.

8. It has a pressure gauge that the operator can check the pressure easily.

9. It can be used for the machines requiring strictly rationing grease flow. It usually works with rubber or plastic machines, press machines, machine centers, woodworking machines, etc.

HOLD WELL INDUSTRIAL CO., LTD.

製品の説明 :

● With a U-Drive unit commanding the feed control of the tool slide and the tool placement even during rotation, it is made to o er the solution to a series of processes such as threading, conical threading, grooves, slots, curve surface machining and other complex pro

les. It makes it possible to

do turning operations on all machining centers.

● It is designed to be used on automatic tool changers to maximize the working e

ciency.

● Modular tool-holder slide with interchangeable design permits the various tool applications and machining.

● It is specially designed with two counter-weights for automatic balancing, which move opposite to the slide to e ectively eliminate oscillations.

YI CHANG MACHINERY CO., LTD.

製品の説明 :

Regardless of whether you use semi-automatic drilling machines, manual tapping & drilling machines, pneumatic machine, hydraulic machine or gear type machine, they can be assemble with multiple spindle head and servo slides to greatly enhance work efficiency while meeting diverse production needs.

This machine type combines mature semi-automatic technologies such as pneumatic, hydraulic, and gear type systems, assemble with multiple spindle head and servo slides, expanding the application range of drilling and tapping machines and making them more adaptable to various production requirements.

If you have any thoughts or inquiries about our machine, please leave a comment below or call our company. We look forward to engaging and communicating with you!