展示テーマ

デジタルトランスフォーメーション

グリーントランスフォーメーション

WELE MECHATRONIC CO., LTD.

製品の説明 :

1.立車主軸轉盤以進口交叉滾子軸承設計,確保重負荷的能力及長期的精度壽命。

2. Z軸226 mm方型滑枕搪孔軸採硬軌配Turcite B結構,VTC1612-CW標準行程900mm。

3.底座、立柱、橫樑、工作台等大型鑄件依製造需要,經由最新的3D設計,剛性最佳化,並以

多年經驗訂定有效的退火程序以消除殘餘應力,多年實際應用經驗,確實能達成有效的長期精

度保持性。

4.X、Z軸標準配備採用「雙編碼器」的「雙」半閉環回饋系統,經濟有效的提高各軸的定位精度。

(X、Z軸可選購德國Heidenhain或西班牙FAGOR光學尺)。

5.VTC-CW標準刀庫容量為16P(16儲位),車刀型式及分配數目可依客戶要求處理。

6.主軸箱等關鍵零件係利用自有的「大型臥式鏜孔機」及「大型高精度三次元量測儀(三座標量床)」

確實達成應有的加工精度,確保優良的組裝基礎。

7.承襲歐美先進工具機廠的標準,以嚴格維護的「1.2米x1.2米」高精密度的方形標準平板做為精密

精度的基礎,對各項關鍵零件進行精密鏟花(刮研),使機器的各處結合面和滑動面均能達到正確的

幾何精度,確保機器應有的精度和壽命。

8.搭配高規格的Fanuc數控系統,標準功能包含:15吋彩色液晶螢幕、Fanuc全鍵式操作面板、

2MB記憶容量、Ethernet網路接口、Flash記憶卡插口、剛性攻牙及各種特殊補間(插補)等多項

高規格功能,能經濟有效的滿足各種使用需求。

9.採用的各項配套零組件均經過長期使用驗證,可確保機器長期運行的可靠性。

10.完整的品檢測試流程,搭配先進的自動光學直準儀、雷射干涉儀、球桿檢測儀、線上動平衡儀等

精密檢測儀器,確保出廠的機器都能達到設計的性能和應有的功能。

11.經驗豐富的研發團隊,突破老舊的包袱,協助客戶達成各種特殊需求。

12.兼具經驗和熱誠的服務團隊和完整的服務體系,可以及時有效的讓用戶的機器長保最佳使用狀態。

CHIAH CHYUN MACHINERY CO., LTD.

製品の説明 :

SY2-42 Swiss-type CNC Lathe

■ SY2-42E has Ø42mm maximum bar feeding dia. and provide the option to go with or without a guide bush to achieve optimum machining condition.

■ Main spindle tool system can install 6 radial live tools, 3 axial live tools, 6 O.D. tools, 5 I.D. tools.

■ Sub Spindle tool system can install 8 ER-20 live tools, combines with the Y2 linear axis and C2 rotating axis to perform the more complex turning and milling process.

ROYAL PRECISION TOOLS CORPORATION

製品の説明 :

▶High speed

▶High precision, high efficiency

▶High dynamic rotary accuracy

▶Balancing adjustment within G1, low vibration

▶Modularized easily

▶Thermal displacement, high stability

▶Short overall length, low inertia

▶High motor power, high moments of inertia

▶Applications: Milling, turning, mill-turn, multi-spindle

HYDROKOMP GmbH

製品の説明 :

The rotary lever clamp is especially suited for clamping fixtures with only little space for the installation of clamping elements. Its construction and compact design allows flexible solutions at various installation conditions. HYDROKOMP offers hydraulic rotary lever clamps which are single-acting as well double-acting. They are used in clamping fixtures whose oil supply is made through drilled channels. To swing down the clamping arm, the linear motion is used pro rata which clamps the workpiece. To unclamp, the clamping arm swings back to where the workpiece can be safely taken out.

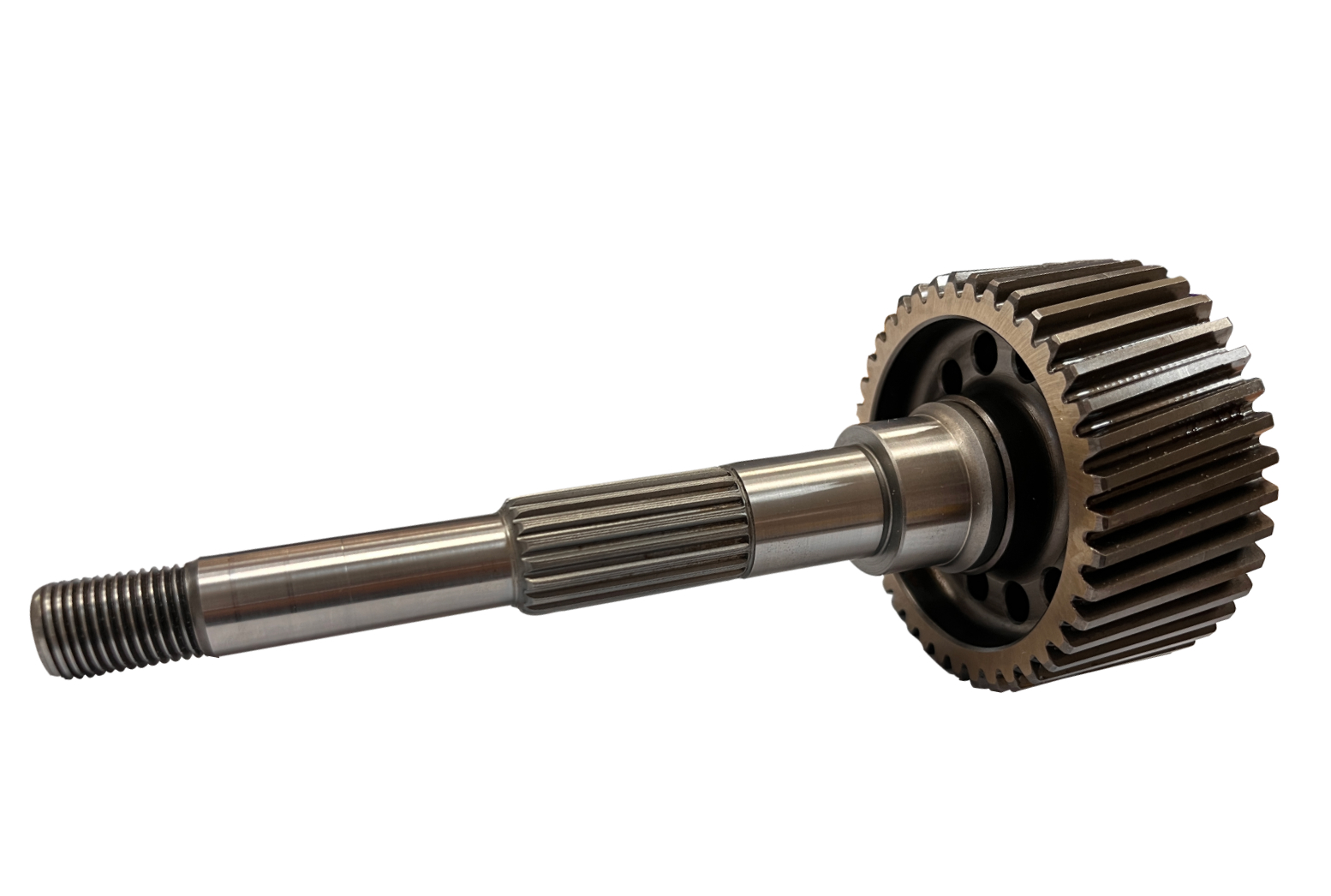

KO-YAN PRECISE MACHINERY CO.,LTD

製品の説明 :

GO-354 CNC Cylindrical Grinding machine combines plunge feed grinding angular feed grinding in one with high investment efficiency. The GO-354 exhibits extraordinary machining accuracy with circularity reaching 0.8 um. It is compactly constructed, occupying a small floor area. Outstanding machine features also include high efficiency, high precision and high productivity.

Machine Features

-Plunge and angular feed grinding.

-Highly rigid machine structure ensures the best possible stability during grinding.

-X, Z-axis are designed with ¡¨V¡¨ and flat slideways.

-Equipped with DITTEL audio sensor for monitoring the grinding quality.

-The tailstock has air floating function.

-Helical grinding and non-circular grinding (optional).

-Grinding speed can reach 50

m/min.

-Circularity accuracy: 0.8 um.

-This machine is equipped with a FANUC Oi-TF CNC controller.

-Selection of various parts loading / unloading devices (optional).

-Measurement system on machine (optional).

-Automatic balancing system can display the unbalanced condition of grinding wheel (optional).

Taiwan Auto-Design Co.

製品の説明 :

// SolidMEN-300的優點

✅ 材料: 不綁材料僅建議合格廠商,未來可自行選用適合材料

✨ 雷射: 德國 500W 水冷式雷射穩定性佳

⚡ 層厚: 層厚可控範圍 10~100μm (最小進給單位 10μm)

🛠️ 成品: 可列印多種金屬材料,強度超過鑄造,可作為表面後處理及拋光使用

🔬 研發: 不綁參數開放製程研究,未來材料無受限可自行開發

⬆️ 尺寸: 300x300x300 可製作大尺寸工件,另有機型可增大或縮小

💎 緻密度>99.5%,品質優於鑄造,近似鍛造

🤖 搭配遠端資訊與智能化視覺模組,方便製程穩定性及智慧化整合。

(即時錄影、列印層數/高度、雷射功率、粉未剩餘量、腔體含氧量、製程時間等)