展示テーマ

デジタルトランスフォーメーション

グリーントランスフォーメーション

KTR TAIWAN LTD.

製品の説明 :

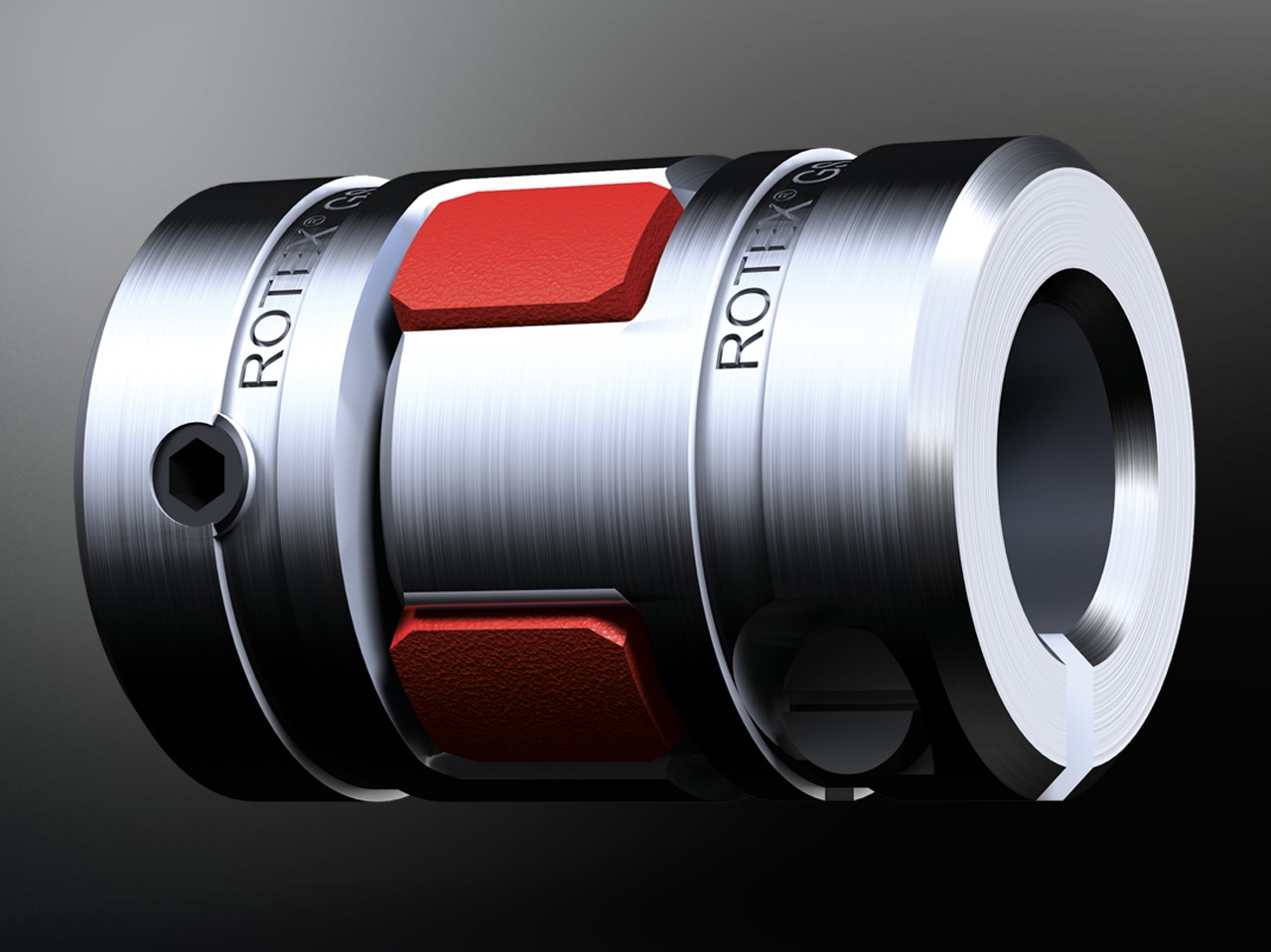

ROTEX® GS is a three-part coupling, backlash-free under pre-stress. The different hub designs and the different Shore hardnesses offer the optimal coupling for each application in automation engineering. In spite of its vibration-damping characteristics it is torsionally stiff so that it is not necessary to make any concessions to accuracy even with highly dynamic servo drives. The ROTEX GS works with the modular system; a high variety of different hub designs is available which can be combined within one coupling size.

TAIWAN FANUC CORPORATION

製品の説明 :

In the current era of high personnel costs. Are you also considering importing automation, but you are worried that the technical threshold is too high and you will not be able to operate it!

Through FANUC QSSR, you can quickly connect with the robot, and use the familiar CNC operation interface to directly operate the robot, simplify the time of getting started with the robot, and quickly introduce automated production.

YIDA PRECISION MACHINERY CO., LTD.

製品の説明 :

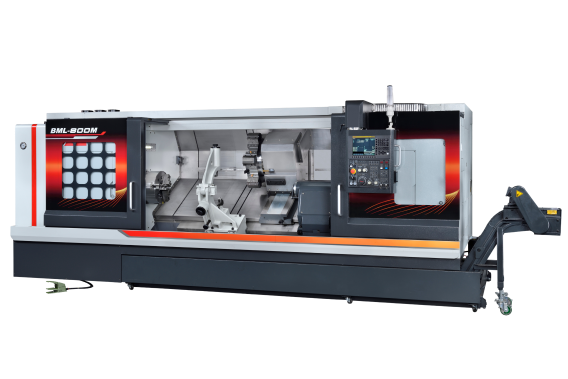

The (B)ML-800 series is a highly customizable turning center with various options for spindle, gearbox, base, tailstock, turret and multiple selectable feed speeds. It can efficiently handle the most demanding machining requirements.

1. The modular structure design of the base has high strength and rigidity. It is molded as a single unit, effectively absorbing the vibrations generated by the machining and providing the stability and precision required for heavy cutting operations, without any distortion or deformation.

2. The optimal modular design spindle features high speed and power, and can be paired with a high-torque output gearbox design, offering a variety of processing options to meet different machining needs.

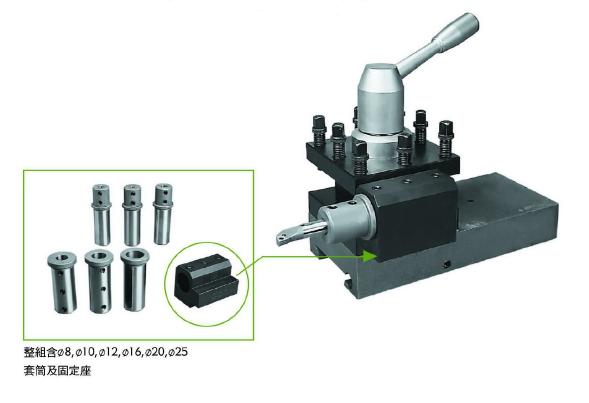

3. The robust toll turret design allows for quick and reliable tool changes, ensuring high efficiency and precision. It caters to the characteristics of various cutting processes, effectively enhancing machining capabilities.

3. The high-strength design of the transmission structure ensures precise positioning and greatly enhances machining efficiency and stability.

4. Ergonomically designed interface makes operation easy and maintenance convenient. Sheet metal design incorporates comprehensive safety considerations.

TAIWAN MACHINE TOOL CO., LTD.

製品の説明 :

The Machine Center for next generation — TLV-850II

Applied field: general hardware processing, mold processing, precision parts

TLV-850II is known for its stability and capability of manufacturing with its high rigidity, which adopts the advantages from TLV-850. Furthermore, it applies the structure which fits the current trend.

-T-slot is used with the common specialization: 18mm

-Z-axis is adopted with the design of high rigidity, a bigger motor, and the strengthened structure so that it leads to perfect swarf performance.

-The tool magazine is well designed to provide the best stability.

-A stronger saddle and an enlarged base frame are also installed to stabilize the performance on cutting.

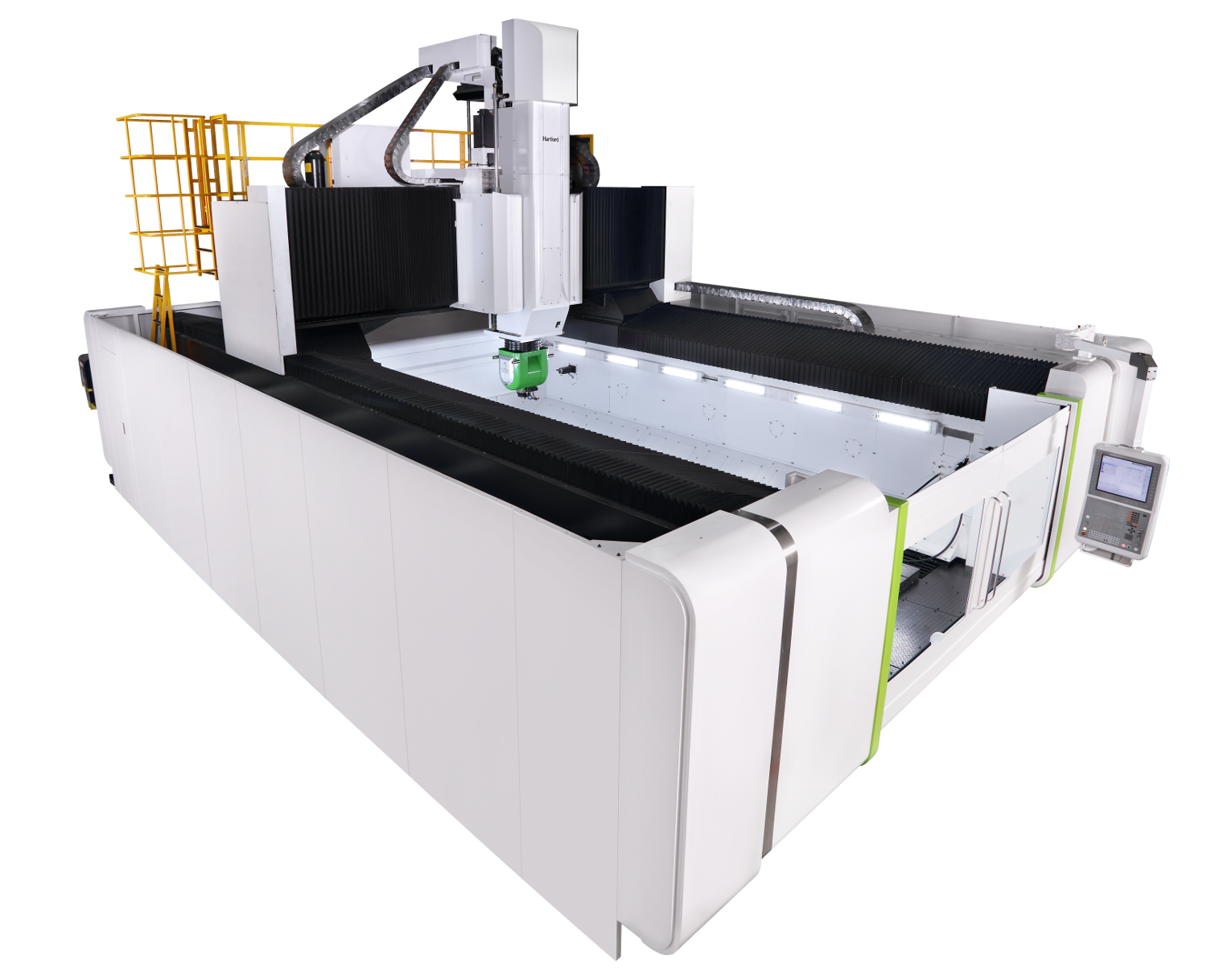

QUASER MACHINE TOOLS, INC.

製品の説明 :

MF700’s design concept is to strengthen Column-moving C frame structure, and separate linear & rotary axes, optimize it with FEMA analyze, the advantages are high rigidity in structure, high precision in machining, and operator friendly. To separate linear & rotary axes is to minimize the following errors and ensure machining accuracy, on top of that, the transmission mechanism/components is away from working area which can reduced parts failure from pollution of coolant and chips.

The linear axes has a cross-frame design, the wide-span column and large-size linear way blocks provides excellent stability during high-speed cutting. Rotary table is intergraded with bridge type column, this compact design can bring us smaller footprint and maximize working envelope.

Rotary table with tailstock support can increase the load capacity which is capable up to 500kg, maximum swing for workpiece is 700mm and height is up to 500mm.

The standard worm gear/wheel and encircling brake design provide high rigidity and lock-force. For different application like high speed demand in aerospace, it can be upgraded with dual Direct Drive Motor.

Operator friendly design with 2 wide open doors are not only easier for operator but also easier for automation upgrade. More thoughtful is we offer three different types of top guards for different work environment, telescope type, solid top cover and open top.

New base design allow chips fall onto conveyor directly, reduce 50% your chip cleaning time.