展示テーマ

デジタルトランスフォーメーション

グリーントランスフォーメーション

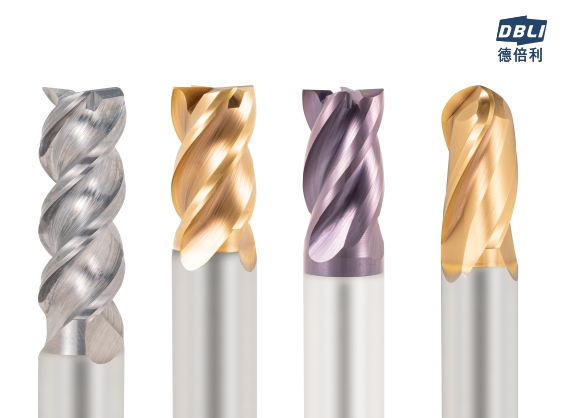

DEEP JET INDUSTRY CO., LTD.

製品の説明 :

1. Use in high speed machining and hard workpiece machining. It improves the quality and machining speed which is the best choice for precision processing.

◆Carbide Asymmetric Corner Radius End Mill (Steel)-Asymmetric helix angle 40º/42º and unequal flute design to effectively reduce the vibration rate and increase the tool's stability.

◆Carbide Asymmetric End Mill (Aluminum)- Reinforced asymmetric 50/50.5/51 and unequal flute design to effectively reduce the vibration rate and increase the tool's stability. This makes the surface smoother.

◆Carbide Asymmetric End Mill (Steel)-Reinforced asymmetric 36º/38 º design with special grinding technique to reach better surface roughness. Avoid vibration problem during machining and increase tool's stability.

◆Carbide Asymmetric End Mill (Aluminum)- Reinforced asymmetric 44.5º/45º/45.5º design with special grinding technique to reach better surface roughness. Avoid vibration problem during machining and increase tool's stability.

ENSINGER ASIA HOLDING PTE. LTD. TAIWAN BRANCH

製品の説明 :

Polyetheretherketone (PEEK) - TECAPEEK natural is a high performance, high temperature, semi crystalline thermoplastic manufactured by Ensinger and may use Victrex® PEEK 450G or Solvay‘s KetaSpire® KT-820 polymer. The most well known and important member of the polyaryletherketone group combines excellent wear, and very good mechanical properties, even under thermal load. Outstanding chemical resistance and a high operating temperature (up to 260°C) round out its profile, and make TECAPEEK an almost universally appropriate material for highly stressed parts.

ACCUTEX TECHNOLOGIES CO., LTD.

製品の説明 :

Linear Shaft Motor

Rapid servo control, enhancement of sensitivity in discharge gap control. Improving cutting speed up to 8~10%

1/1000 High Resolution Signal Process

High resolution in linear scale, achieve more smooth velocity control, and enhance the stability of position control, best match up contouring accuracy.

Stable Discharge Board (SD-Master)

Irregular Thickness Cutting

The AccuteX intelligent discharge unit is capable of dealing with the changing conditions in workpiece thickness and water flushing situations, featuring high cutting speed, and free from wire breaking problems.

PCD Cutting & Graphite Machining Power supply

The collapse of workpiece edge by wire cut can be controlled within minimum range along with high speed machining.

PROTH INDUSTRIAL CO., LTD.

製品の説明 :

1.A : Auto-cross H : Hydraulic longitudinal R : Rapid up/down.

2.Overall architecture (horizontal module) : Overall structural design optimization /lightweight/stiffness strengthen.

3.Built-in spindle (15HP) with 20 inches grinding wheel.

4.Workpiece shape : flat grinding/step/plunge grinding.

5.Machine drive : Cross and vertical liner guide way, longitudinal double V guide way.

KAO MING MACHINERY INDUSTRIAL CO., LTD.

製品の説明 :

1. 機器結構為工作台固定,橫樑前後移動之高架式設計。<br />

<br />

2. 高剛性結構最適合超長超大工件之加工。加工精度極穩定。<br />

<br />

3. 超大三軸行程: X軸: 6.5~14.5米<br />

Y軸: 2.5/ 3.1/ 3.7米<br />

Z軸: 1.2米<br />

4. 整體佔地面積比一般機台節省25%以上<br />

<br />

5. 固定式工作台最大荷重能力高達10,000 kgf/m2。<br />

<br />

6. 採用FEA有限元素分析法,模擬機器變形與振動模式,以獲得最強的結構與最佳化設計。<br />

<br />

7. X,Y軸安裝機械式預壓齒輪條驅動減速機構,能獲得幾乎零背隙的線性精度。<br />

<br />

8. X,Y 軸方形硬軌都採用階梯式設計。使橫樑及主軸頭在重切削及快速進幾下能保有穩定的切削性能。<br />

<br />

9. 自動臥式換刀機構整合於原有立式換刀系統;簡化設計,具獨創性。標準頭配備立式頭及臥式頭之2個位置AAC自動執行換頭動作。更多附加頭需求時,可擴充頭庫至3-5個位置。<br />

HO CHEN MACHINERY & ELECTRIC IND. CO., LTD.

製品の説明 :

XYZ axes travel: 600x400x400mm (23.62"x15.74"x15.74")

W axis travel: 450mm (17.71")

Work table: 650x450mm(25.59"x17.71")

Max. Workpiece: 900x500x300mm(35.43"x19.68"x11.81")

Max. Workpiece weight: 700kg

Distance from table to guide plate:25~425mm(0.98"x16.73")

Machine dimensions: 1580x1250x2740(62.2"x49.21"x107.87")

Machine net weight: 1200kg

Electrode diameter: 0.2~3.0mm

Dielectric fluid: pure water ( dielectric oil for 0.2mm or below)

Filtration: Paper filter

Controlling axes XYZW

Monitor: 15” LCD screen

Input/output unit: LAN/USB

Min. Setting Unit: 0.001mm

Min. Moving Unit: 0.001mm

Graphical display: 2D

Machine Features

1. This system utilizes Windows CE controller.

2. Able to store data through USB and internet.

3. Dialogue window, along with picture description functions.

4. Touchscreen type interface.

5. Special repaired frames to quicken the maintenance speed.

6. Close-Loop design of digital feedback on three axis of the machine, significantly increases positioning accuracy.

7. Possessing good and simple operation interfaces

Common function keys are located on the operation panel for direct use, hot key function on screen for quick access.

8. ATC (automatic tool changer) and AGC(automatic guide chnger) can be installed

9. Unlimited number of machining conditions can be saved as machining archives. Each set of machining conditions can be edited, modified or stored. They are easy to edit and easy to search.

10. Automatic origin search and multi-point coordinate memory capability.

11. Chinese/English versions, Metric/British system switch and quick up, quick down, and slow up and slow down capabilities, resolution can reach 1um.

12. All alarms describe the source, data and exact time of problem occurrence.

13. Able to proceed standard GM code and extra GM code

14. Able to proceed DXF file transfer to position coordinate function

15. AB axis rotate table can be installed

16. Position simulation and work route can be displayed

17. During discharge change new electrode can automatically compensate depth

18. Backlash point automatic compensate function

19. Able to do single hole drilling, multiple hole drilling and multi thickness drilling

20. Blindhole drilling function, any depth can be set

21. Initial current can set to reduced value, which can prevent workjob surface damage

22. Initial polarity reverse function, can prevent uneven electrode caused efficiency decrease

23. Six axis linear interoperate accelerate speed movement

24. Input, output, various of machine status real time display system

25. Discharge program and parameter conversion function

Accessories

《 Standard Accessories for High-speed Drilling CNC EDM 》

Tool Box*1

Brass Electrode 1.0mm*10

Electrode Guide 1.0mm*1

Standard Chuck*1

Foot Pads*1 set

Filter*1

Rubber Seal*10

Halogen Work Lamp*1

Flushing Unit*1 set

《 Optional Accessories for High-speed Drilling CNC EDM 》

ATC

Electrode Guide(Other diameters)

Brass Electrode(Other diameters)

ER Type Chuck for electrodes up to 6mm

Submerged Work Tank

75Amp Power upgrade

Filtration System with Resin Bottle

A,B Axes

Automatic guide changer 3/6

FOCUS CNC CO., LTD.

製品の説明 :

30-degree slant bed provides high-stiffness capacity, long-term stability and excellent chip removal capability. Compact design makes the machine length shorter and the floor space smaller. To efficiently utilize the floor space, the chips can be discharged from the side or rear of the machine. To clean the coolant tank from the front of machine to make the plant layout easier. Auto load/unload system provides graphic user interface, quick setup for different work-piece, customized program and work-piece counter. Efficient loading/unloading and quick work-piece swap makes better performance.

PALMARY MACHINERY CO., LTD.

製品の説明 :

Based on PALMARY's tradition of "Pursuing Quality Perfection", combined with human engineering design and peak performance concepts, each machine fully reflects PALMARY's unmatched design and technique.

Honeycomb type machine structure assures the best possible rigidity and stability. The machine bed is manufactured from high-quality Meehanite cast iron, heat treated and stress relieved for outstanding stability and without deformaiton.