展示テーマ

デジタルトランスフォーメーション

グリーントランスフォーメーション

INNOSERV FA INC. TAIWAN BRANCH (BVI)

製品の説明 :

Micro Dynamics Vertical Machining Center Line opens a new era in multi-purpose and versatile machining centers. Compact, durable, powerful, strong and accurate, the MEGA/TERA Series starts a revolution in the market: the smallest C-frame machines provide powerful and precise results for manufacturers of dies and molds, aerospace, automotive, semi-conductor, job shops and general machine sectors.

The MEGA/TERA Series has been designed with the latest in technology being utilized throughout the machine with productivity in mind. From its EtherNet/IP architecture for easy automation and integration into systems and cells, to its Motion Control for fast and smooth operations used in all industries, the MEGA/TERA Series has quickly become one of the industries leading machine tool lines of Vertical Machining Centers.

The MEGA/TERA Series has been refined through years of research and development of new technologies that greatly enhance the machines for the rigors of the Mold and Die industry.

All series are equipped with

■ 15,000 rpm Built-In Spindle

■ Thermal Compensation (DYPEC)

■ Micro Dynamics HMI

TES ELECTRICAL ELECTRONIC CORP.

製品の説明 :

FEATURES

Automatic ferrous or non-ferrous substrate

material measurement

Non-magnetic coating on ferrous metal

substrate and insulating coating on

non-ferrous metal substrate measurement

Audible and visual warning when tolerance

limits are exceeded

Statistical display of significant values such as

mean value, standard deviation, min, max values

Units of measurement μm/mils select

LCD display with backlight

Auto power off

Ametek Taiwan Corp., Ltd.

製品の説明 :

Talyrond 565 H/HS/T & 585 H/HS/T: It is widely used in precision machining, machinery, bearing, metrology, optics industries as a multi-functional ultra-precision roundness instrument.

Talyrond 2000:It is suitable for high precision measurement of roundness and cylindrical geometry of large, heavy or complex parts.

Talyrond 1700 & 1520 & 565XL & 585XL: The best choice of measuring large diameter parts and asymmetrical rotating parts.

Talyrond 130 & 131C & Surtronic Roundness:Powerful economic roundness and cylindricity high precision measurement system & roundness measurement instrument widely used in bearing industry workshops, characterized by fast, durable and high precision.

SGCAM TECHNOLOGY CO., LTD.

製品の説明 :

主功能介紹:<br />

全中文畫面,易學、易懂、易用,為加工業最適合的加工軟體,操作軟體完全不用背指令。<br />

可由AutoCAD製圖畫出工件外形,再匯入DXF、IGS圖檔,轉換為CNC程式碼。<br />

不必畫3D圖形,一條輪廓線和一條路徑線一般2D圖即可輕鬆轉出車銑的加工程式。<br />

快速C軸填充式的輸入方式 ,很簡單的方式就能轉出C軸加工程式。<br />

參數式的C軸工法操作條件更改G碼自動跟著改變。<br />

製作程式時車銑工法可依加工順序任意作排序調整。<br />

3D實體切削模擬預覽,可避免干涉及過切事件發生。<br />

主軸和副主軸的獨動或同動會自動等待(指定機型) 。<br />

同一個程式中可同時指定不同的切削計算方式有走刀式、走心式、櫛式。<br />

車銑的刀具庫參數可依實際機台型號的刀具位置做個別指定。<br />

可在端面、圓弧面、橢圓面上做刻字。<br />

支援單筆劃字型刻字。<br />

系統支援:<br />

支援廠牌有Citizen 、Star、Miyano、Tsugami、洽群、縉錩、利高、精機、瀧澤、程泰、寶麗金…<br />

支援側銑側鑽等循環加工指令G87、G88、G184<br />

支援極座標G12.1 、G13.1、 G112 、G113<br />

支援圓筒補間G07.1、G107

Taiwan Machine Tool & Accessory Builders’ Association

製品の説明 :

TMBA's members can join below 10 committees by their interest:

1. Machining Center Issue committee.

2. Turning Center Issue committee.

3. Forming Machine Tool Issue committee.

4. Non-traditional Machine Tools(EDM, Laser,…,etc) Issue committee.

5. Multi-Tasking(/Integrated) Machine Tool Issue committee.

6. Grinding Machine Tool Issue committee.

7. Functional components Issue committee.

8. Raw Material and Processing Issue committee.

9. Transmission component Issue committee.

10. Accessories & Hardware Issue committee.

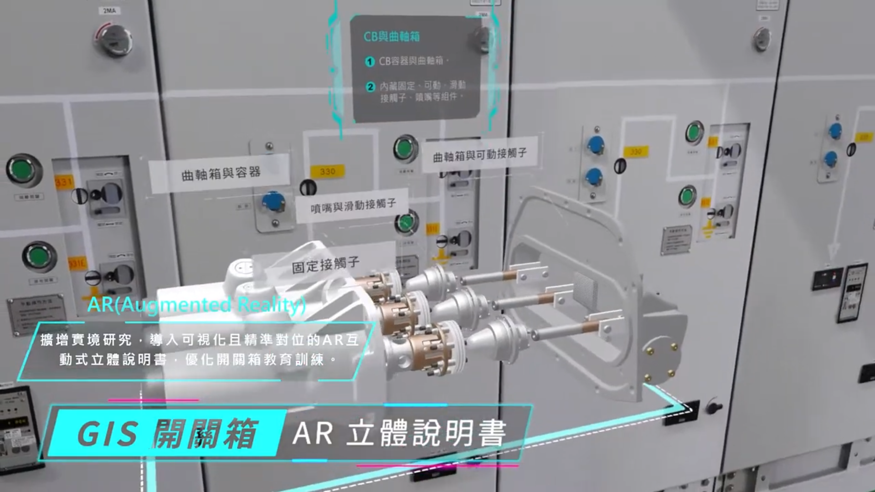

Administration for Digital Industries, moda

製品の説明 :

The Industrial XR SOP Solution""utilizes AR/VR/MR cross-platform integration technology to ensure seamless operation across various devices such as smartphones and head-mounted displays. It is specifically designed for the industrial sector as an XR intelligent carbon reduction integration platform service.

It's key features include support for ""cross-temporal"" information transmission and real-time monitoring, enabling precise and instant ""cross-span"" collaboration capabilities. Through the integration of virtual and augmented reality, information is transformed into a ""visualized"" presentation, allowing users to intuitively understand and operate, thereby assisting enterprises in effective resource management, reducing waste, and helping industrial production lines lower carbon footprints. This, in turn, improves energy efficiency and achieves a more environmentally friendly production model.

The application scope covers various stages of industrial production, including machine equipment, factory premises, vocational training, remote collaboration, maintenance and operation, and business showcases. Through comprehensive cross-platform integration technology, it provides intelligent, efficient, and eco-friendly solutions.